Installation, testing and commissioning

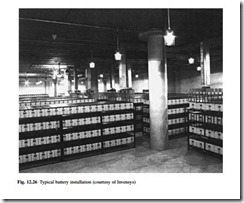

Larger lead acid or nickel cadmium installations should be sited in a correctly constructed room, vehicle, cubicle or rack which allows ready access for maintenance and ensure adequate ventilation of batteries and battery chargers. The battery should not be located close to a source of heat such as a transformer or heater. Battery racks should adhere to recommendations regarding spacing between cells, and drip trays and insulators should be fitted where applicable. All cell connections should be cleaned, coated with no-oxide grease and tightened to the suppliers’ specification. A typical installation is shown in Fig. 12.26.

The rating of the ac mains input cable to the battery charger should be based on the peak current that will be drawn by the charger at the lowest mains voltage. The rating of the dc cables from the battery charger and in the battery should be no lower than the maximum protection fuse rating, and attention should be paid to the overall volt- age drop in the system, especially on lower voltage dc systems. The cables should be adequately protected, and segregation may be necessary on systems with large dc current.

It may be necessary to charge batteries for several days before their full capacity is reached, and in some cases a special initial commissioning charge level may be required.

Tests should be set up so that the results enable the operation of the system to be compared with the original specification. For larger systems, the manufacturer should propose a set of witness tests to be performed at the works, followed by final tests to prove capacity and duty on site. A typical test schedule should be designed to establish:

● the ability of the battery charger to support the standing load, where applicable

● the ability of the battery charger to recharge a fully discharged battery in the required time, whilst simultaneously supporting the standing load, again where applicable

● the ability of the battery charger to maintain regulation within specified limits throughout the required range of load and input conditions

● correct operation of the monitoring features and instrumentation

● the ability of the battery and charger system to supply the load for the required period during a power failure