Speed Control of Universal Motors

The following methods are usually employed for speed-control purposes :

(i) Resistance Method. As shown in Fig. 36.50, the motor speed is controlled by connecting a variable resistance R in series with the motor. This method is employed for motors used in sewing machines. The amount of resistance in the circuit is changed by means of a foot-pedal.

(ii) Tapping-field Method. In this method, a field pole is tapped at various points and speed is controlled by varying the field strength (Fig. 36.51). For this purpose, either of the following two arrangements may be used :

(a) The field pole is wound in various sections with different sizes of wire and taps are brought out from each section.

(b) Nichrome resistance wire is wound over one field pole and taps are brought out from this wire.

(iii) Centrifugal Mechanism. Universal motors, particularly those used for home food and drink mixers, have a number of speeds.Selection is made by a centrifugal device located inside the motor and connected, as shown in Fig. 36.52. The switch is adjustable by means of an external lever. If the motor speed rises above that set by the lever, the centrifugal device opens two contacts and inserts resistance R in the circuit, which causes the motor speed to decrease. When motor runs slow, the two contacts close and short-circuit the resistance, so that the motor speed rises.

This process is repeated so rapidly that variations in speed are not noticeable.

The resistance R is connected across the governor points as shown in Fig. 36.52. A capacitor C is used across the contact points in order to reduce sparking produced due to the opening and closing of these points. Moreover, it prevents the pitting of contacts.

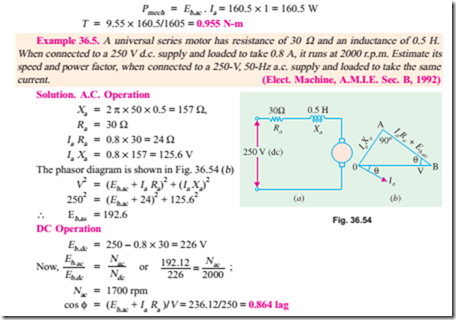

Example 36.4. A 250-W, single-phase, 50-Hz, 220-V universal motor runs at 2000 rpm and takes 1.0 A when supplied from a 220-V dc. supply. If the motor is connected to 220-V ac supply and takes 1.0 A (r.m.s), calculate the speed, torque and power factor. Assume Ra = 20 W and La = 0.4 H.

Unexcited Single-phase Synchronous Motors

Unexcited Single-phase Synchronous Motors

These motors

1. operate from a single-phase a.c. supply

2. run at a constant speed – the synchronous speed of the revolving flux

3. need no d.c. excitation for their rotors (that is why they are called unexcited)

4. are self-starting.

These are of two types (a) reluctance motor and (b) hysteresis motor.