Universal Motor

A universal motor is defined as a motor which may be operated either on direct or single-phase supply at approximately the same speed and output.

In fact, it is a smaller version (5 to 150 W) of the a.c. series motor described in Art. 36.16. Being a series-wound motor, it has high starting torque and a variable speed characteristic. It runs at dangerously high speed on no-load. That is why such motors are usually built into the device they drive.

Generally, universal motors are manufactured in two types:

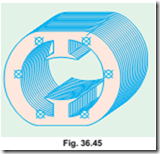

1. concentrated-pole, non-compensated type (low power rating)

2. distributed-field compensated type (high power rating)

The non-compensated motor has two salient poles and is just like a 2-pole series d.c. motor except that whole of its magnetic path is laminated (Fig. 36.45). The laminated stator is necessary because the flux is alternating when motor is operated from a.c. supply. The armature is of wound type and similar to that of a small d.c. motor. It consists essentially of a laminated core having either straight or skewed slots and a commutator to which the ture winding are connected. The distributed-field compensated type motor has a stator core similar to that of a split-phase motor and a wound armature similar to that of a small d.c. motor. The compensating winding is used to reduce the reactance voltage present in the armature when motor runs on a.c. supply. This voltage is caused by the alternating flux by transformer action (Art. 36.16).

transformer action in a coil during its commutation period is not sufficient to cause any serious com- mutation trouble. Moreover, high-resistance brushes are used to aid commutation.

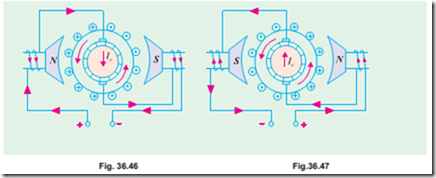

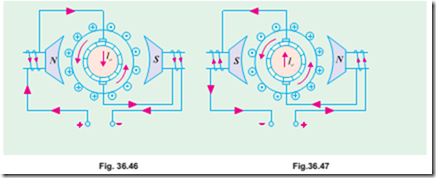

(a) Operation. As explained in Art. 36.16, such motors develop unidirectional torque, regard- less of whether they operate on d.c. or a.c. supply. The production of unidirectional torque, when the motor runs on a.c. supply can be easily understood from Fig. 36.46. The motor works on the same principle as a d.c. motor i.e. force between the main pole flux and the current-carrying armature conductors. This is true regardless of whether the current is alternating or direct (Fig. 36.47).

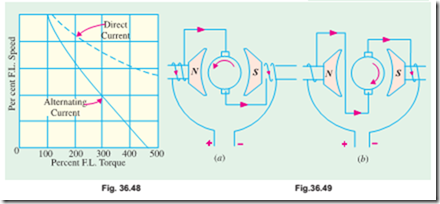

Speed/Load Characteristic. The speed of a universal motor varies just like that of a d.c. series motor i.e. low at full-load and high on no-load (about 20,000 r.p.m. in some cases). In fact, on no-load the speed is limited only by its own friction and windage load. Fig. 36.48 shows typical torque characteristics of a universal motor both for d.c. and a.c. supply. Usually, gear trains are used to reduce the actual load speeds to proper values.

(c) Applications. Universal motors are used in vacuum cleaners where actual motor speed is the load speed. Other applications where motor speed is reduced by a gear train are : drink and food drills and domestic sewing machine etc.

(d) Reversal of Rotation. The concentrated-pole (or salient-pole) type universal motor may be reversed by reversing the flow of current through either the armature or field windings. The usual method is to interchange the leads on the brush holders (Fig.36.49).

The distributed-field compensated type universal motor may be reversed by interchanging either the armature or field leads and shifting the brushes against the direction in which the motor will rotate. The extent of brush shift usually amounts to several commutator bars.

Related posts:

Incoming search terms:

- single phase universal motor

- universal motor single phase

- single phase series universal motor

- a universal moter can on

- universal motor uses for instrument

- unversal motor vs single phase motor

- which single phase motor run at a dangerously high speed without a load?

- why compensated winding used in compensated type universal motor

- why universal motors are used in vacuum cleaners

- universal motor -working principle

- univarsal motor in image

- univarsal moter single phase moter

- single phase ac universal motor

- operating principle of series universal motor

- motor universal dan single phase motor

- load test on universal motor

- gear train in universal motor

- wwwunivarsal com