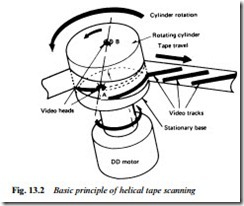

HELICAL TAPE SCAN

The tape is wrapped around approximately 180° of the drum’s periphery and takes a helical path due to the tilting of the head drum and a precision-machined guide rabbet on the lower (stationary) part of the head drum. The head assembly spins anticlockwise at 1500 r.p.m. which confers the required high writing speed. All that is required of the tape transport system now is that it moves the tape along by one track-width per head scan in order that successive tracks are laid down side by side and just abutting each other during record. At playback the same tape-transport system ensures that as each new

head sweep presents itself to the tape wrap a fresh track is lined up in its path for readout. In a typical system using 49 μm-wide video tracks the tape progresses through the deck at 2.34 cm/s, pulled around the head drum by a downstream capstan/pinch wheel assembly. At the entry and exit point of the tape’s head-drum wrap are positioned guides which precisely align the path of the tape around the drum; these and other mechanical aspects of the deck will be examined in detail in Chapter 18.

The head-tips must maintain intimate contact with the magnetic surface of the tape. In audio-recorder practice this is achieved by the use of pressure-pads which hold the tape tight against the heads. That is obviously impractical in a helical-scan system, where a degree of lateral tension is imparted to the tape in its head-wrap by (a) a back– tension brake on the feed spool; and (b) the friction of the tape against the surfaces of the upper and lower head-drum sections. Against the taut tape ribbon the rotating videohead-tips, which project about 50 μm from the drum face surface, push out a moving ‘stretch-spot’ in which the required head-tape pressure is set up.