Types of IFR turbine

In the centripetal turbine, energy is transferred from the fluid to the rotor in passing from a large radius to a small radius. For the production of positive work the product of Ucθ at entry to the rotor must be greater than Ucθ at rotor exit (Eq. (1.18c)). This is usually arranged by imparting a large component of tangential velocity at rotor entry, using single or multiple nozzles, and allowing little or no swirl in the exit absolute flow.

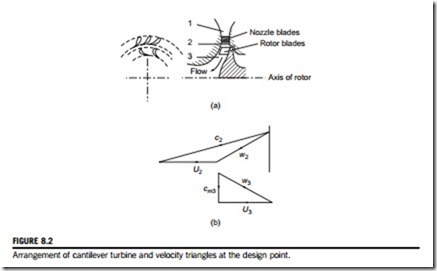

Cantilever turbine

Figure 8.2(a) shows a cantilever IFR turbine where the blades are limited to the region of the rotor tip, extending from the rotor in the axial direction. In practice the cantilever blades are usually of

the impulse type (i.e., low reaction), by which it is implied that there is little change in relative velocity at inlet and outlet of the rotor. There is no fundamental reason why the blading should not be of the reaction type. However, the resulting expansion through the rotor would require an increase in flow area. This extra flow area is extremely difficult to accommodate in a small radial distance, especially as the radius decreases through the rotor row.

Aerodynamically, the cantilever turbine is similar to an axial-impulse turbine and can even be designed by similar methods. Figure 8.2(b) shows the velocity triangles at rotor inlet and outlet. The fact that the flow is radially inwards hardly alters the design procedure because the blade radius ratio r2/r3 is close to unity anyway.

The 90 IFR turbine

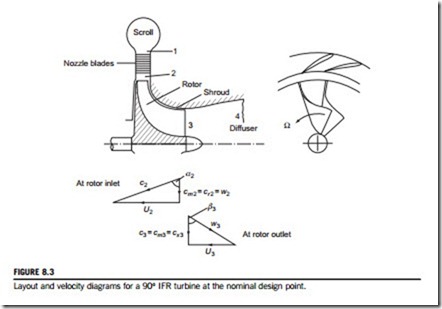

Because of its higher structural strength compared with the cantilever turbine, the 90o IFR turbine is the preferred type. Figure 8.3 shows a typical layout of a 90o IFR turbine; the inlet blade angle is generally made zero, a fact dictated by the material strength and often high gas temperature. The rotor vanes are subject to high stress levels caused by the centrifugal force field, together with a pulsating and often unsteady gas flow at high temperatures. Despite possible performance gains the use of nonradial (or swept) vanes is generally avoided, mainly because of the additional stresses that arise due to bending. Nevertheless, despite this difficulty, Meitner and Glassman (1983) have considered designs using sweptback vanes in assessing ways of increasing the work output of IFR turbines.

From station 2, the rotor vanes extend radially inward and turn the flow into the axial direction. The exit part of the vanes, called the exducer, is curved to remove most if not all of the absolute

tangential component of velocity. The 90o IFR turbine or centripetal turbine is very similar in appearance to the centrifugal compressor of Chapter 7, but with the flow direction and blade motion reversed.

The fluid discharging from the turbine rotor may have a considerable velocity c3 and an axial diffuser (see Chapter 7) would normally be incorporated to recover most of the kinetic energy, ð1=2Þc2, which would otherwise be wasted. In hydraulic turbines (discussed in Chapter 9), a diffuser is invariably used and is called the draught tube.

In Figure 8.3, the velocity triangles are drawn to suggest that the inlet relative velocity, w2, is radially inward, i.e., zero incidence flow, and the absolute flow at rotor exit, c3, is axial. This con- figuration of the velocity triangles, popular with designers for many years, is called the nominal design condition and will be considered in some detail in the following pages. Following this the so-called optimum efficiency design will be explained.