PROBLEMS

Note: In problems 1-6 assume γ and R are 1.4 and 287 J/(kg oC), respectively. In problems 2-6 assume the stagnation pressure and stagnation temperature at compressor entry are 101.3 kPa and 288 K, respectively.

1. A cheap radial-vaned centrifugal fan is required to provide a supply of pressurized air to a furnace. The specification requires that the fan produce a total pressure rise equivalent to 7.5 cm of water at a volume flow rate of 0.2 m3/s. The fan impeller is fabricated from 30 thin sheet metal vanes, the ratio of the passage width to circumferential pitch at the impeller exit being specified as 0.5, and the ratio of the radial velocity to blade tip speed as 0.1. Assuming that the overall isentropic efficiency of the fan is 0.75 and that the slip can be estimated from Stanitz’s expression, Eq. (7.34b), determine

a. the vane tip speed;

b. the rotational speed and diameter of the impeller;

c. the power required to drive the fan if the mechanical efficiency is 0.95;

d. the specific speed.

For air assume the pressure is 105 Pa and the temperature is 20oC.

2. The air entering the impeller of a centrifugal compressor has an absolute axial velocity of 100 m/s. At rotor exit the relative air angle measured from the radial direction is 26o360, the radial component of velocity is 120 m/s, and the tip speed of the radial vanes is 500 m/s.

Determine the power required to drive the compressor when the air flow rate is 2.5 kg/s and the mechanical efficiency is 95%. If the radius ratio of the impeller eye is 0.3, calculate a suitable inlet diameter assuming the inlet flow is incompressible. Determine the overall total pressure ratio of the compressor when the total-to-total efficiency is 80%, assuming the velocity at exit from the diffuser is negligible.

3. A centrifugal compressor has an impeller tip speed of 366 m/s. Determine the absolute Mach number of the flow leaving the radial vanes of the impeller when the radial component of velocity at impeller exit is 30.5 m/s and the slip factor is 0.90. Given that the flow area at impeller exit is 0.1 m2 and the total-to-total efficiency of the impeller is 90%, determine the mass flow rate.

4. The eye of a centrifugal compressor has a hub-tip radius ratio of 0.4, a maximum relative flow Mach number of 0.9, and an absolute flow that is uniform and completely axial. Determine the optimum speed of rotation for the condition of maximum mass flow given that the mass flow rate is 4.536 kg/s. Also, determine the outside diameter of the eye and the ratio of axial

velocity-blade speed at the eye tip. Figure 7.12 may be used to assist the calculations.

5. An experimental centrifugal compressor is fitted with free-vortex guide vanes to reduce the relative air speed at inlet to the impeller. At the outer radius of the eye, air leaving the guide

vanes has a velocity of 91.5 m/s at 20o to the axial direction. Determine the inlet relative Mach number, assuming frictionless flow through the guide vanes, and the impeller total-to- total efficiency. Other details of the compressor and its operating conditions are:

Radial vanes at impeller exit

Impeller entry tip diameter, 0.457 m; Impeller exit tip diameter, 0.762 m; Slip factor, 0.9 radial blades at impeller exit;

Radial component of velocity at impeller exit, 53.4 m/s; Rotational speed of impeller, 11,000 rev/min; Static pressure at impeller exit, 223 kPa (abs).

6. A centrifugal compressor has an impeller with 21 vanes, which are radial at exit, a vaneless diffuser, and no inlet guide vanes. At inlet, the stagnation pressure is 100 kPa (abs) and the stagnation temperature is 300 K.

a. Given that the mass flow rate is 2.3 kg/s, the impeller tip speed is 500 m/s and the mechanical efficiency is 96%, determine the driving power on the shaft. Use Eq. (7.34b) for the slip factor.

b. Determine the total and static pressures at diffuser exit when the velocity at that position

is 100 m/s. The total-to-total efficiency is 82%.

c. The reaction, which may be defined as for an axial-flow compressor by Eq. (5.19), is 0.5, the absolute flow speed at impeller entry is 150 m/s, and the diffuser efficiency is 84%. Determine the total and static pressures, absolute Mach number, and radial component of velocity at the impeller exit.

d. Determine the total-to-total efficiency for the impeller.

e. Estimate the inlet-outlet radius ratio for the diffuser assuming the conservation of angular momentum.

f. Find a suitable rotational speed for the impeller given an impeller tip width of 6 mm.

7. A centrifugal pump is used to raise water against a static head of 18.0 m. The suction and delivery pipes, both 0.15 m diameter, have, respectively, friction head losses amounting to 2.25 and 7.5 times the dynamic head. The impeller, which rotates at 1450 rev/min, is 0.25 m diameter with eight vanes, radius ratio 0.45, inclined backward at β0 5 60o. The axial width of the impeller is designed so as to give constant radial velocity at all radii and is 20 mm at impeller exit. Assuming a hydraulic efficiency of 0.82 and an overall efficiency of 0.72, determine

a. the volume flow rate;

b. the slip factor using Busemann’s method;

c. the impeller vane inlet angle required for zero incidence angle;

d. the power required to drive the pump.

8. A centrifugal pump delivers 50 dm3/s of water at an impeller speed of 1450 rev/min. The impeller has eight vanes inclined backward to the direction of rotation with an angle at the tip of β0 5 60o. The diameter of the impeller is twice the diameter of the shroud at inlet and the magnitude of the radial component of velocity at impeller exit is equal to that of the axial component of velocity at the inlet. The impeller entry is designed for the optimum flow condition to resist cavitation (see Eq. (7.20)) has a radius ratio of 0.35 and the blade shape corresponds to a well-tested design giving a cavitation coefficient σb 5 0.3. Assuming that the hydraulic efficiency is 70% and the mechanical efficiency is 90%, determine

a. the diameter of the inlet;

b. the NPSH;

c. the impeller slip factor using Wiesner’s formula;

d. the head developed by the pump;

e. the power input.

Also calculate values for slip factor using the equations of Stodola and Busemann, comparing the answers obtained with the result found from Wiesner’s equation.

9. a. Write down the advantages and disadvantages of using free-vortex guide vanes upstream of the impeller of a high-pressure ratio centrifugal compressor. What other sorts of guide vanes can be used and how do they compare with free-vortex vanes?

b. The inlet of a centrifugal air compressor has a shroud diameter of 0.2 m and a hub diameter of 0.105 m. Free-vortex guide vanes are fitted in the duct upstream of the impeller so that the flow on the shroud at the impeller inlet has a relative Mach number, M1,rel 5 1.0, an absolute flow angle of α1 5 20o, and a relative flow angle β1 5 55o. At inlet the stagnation conditions are 288 K and 105 Pa. Assuming frictionless flow into the inlet, determine

i. the rotational speed of the impeller;

ii. the air mass flow.

c. At exit from the radially vaned impeller, the vanes have a radius of 0.16 m and a design point slip factor of 0.9. Assuming an impeller efficiency of 0.9, determine

i. the shaft power input;

ii. the impeller pressure ratio.

10. Sketch a Mollier diagram showing all the stagnation and static points needed to represent the complete flow process in a diffuser. Derive the following expression for the diffuser efficiency:

Air enters a diffuser with an averaged velocity of 360 m/s at a stagnation pressure and temperature of 340 kPa and 420 K and leaves at a stagnation pressure of 300 kPa with an averaged velocity of 120 m/s and a static pressure of 285 kPa. Determine a. the static pressure and Mach number of the air at inlet;

b. the diffuser efficiency;

c. the Mach number at exit and the overall entropy increase.

Take γ 5 1.4 and Cp 5 287 J/(kg K).

11. At the inlet to an axial diffuser the velocity of the approaching air is 420 m/s, the stagnation pressure is 300 kPa, and the stagnation temperature is 600 K. At exit the stagnation pressure is 285 kPa and the static pressure is 270 kPa. Using compressible flow analysis, determine

a. the static temperature, static pressure, and Mach number at inlet and the diffuser efficiency;

b. the Mach numbers at exit and entry.

For air take γ 5 1.376 and R 5 287 J/(kg K).

12. A centrifugal compressor fitted with 21 radial vanes with an outside diameter of 40 cm is designed to operate at a rotational speed of 17,400 rpm. Assuming that the air admitted is at

101.3 kPa and a temperature of 15oC, determine

a. the absolute Mach number of the flow at the impeller tip given that the radial velocity at that location is 30 m/s;

b. the stagnation pressure of the air leaving the impeller if the total-to-total efficiency of the impeller is 92%;

c. the mass flow of air passing through the compressor if the axial width of the passage at

impeller exit is 2.0 cm.

Assume the Stanitz expression for the slip factor. Take Cp 5 1005 J/(kg K) and γ 5 1.4.

13. a. A model of low-speed centrifugal compressor (a “blower”) runs at 430 rpm and delivers 10 m3/s of air against a pressure head of 60 mm of water. If the pump efficiency is estimated to be 80%, how much power is required to drive the compressor?

b. A geometrically similar compressor is made with a diameter 1.8 times the size of the model and is required to work against a pressure head of 80 mm of water. Determine the operating speed and the power needed to drive the compressor assuming dynamically similar conditions apply.

14. A centrifugal pump is required to deliver 0.09 m3/s of water against a back pressure of 100 kPa. The impeller, which rotates at 1250 rpm, is 0.35 m diameter and has nine vanes swept back at 45o. The axial width of the impeller at its tip is 40 mm. Using Wiesner’s slip correlation (assuming that r1/r2 5 ε in Eq. (7.35d)) determine the specific work done by the impeller. If the efficiency of the pump is 70%, calculate the power needed to drive the pump. Calculate the specific speed and specific diameter of the pump and compare your results with the data given in Chapter 2.

15. Atmospheric air enters the intake diffuser of a jet aircraft flying at a Mach number of 0.9 at a constant altitude where the static pressure and temperature are 25 kPa and 220 K, respectively. The entrance area of the intake is 0.5 m2 and the area at entry to the compressor is 0.8 m2. There is a loss of 10% of the stagnation pressure of the air as it flows to the compressor. Using compressible flow theory and assuming adiabatic flow in the intake, determine the Mach number and velocity of the flow entering the compressor.

16.A prototype centrifugal compressor is to be built with an impeller having 19 vanes backswept at β0 5 30o, rotating at 12,000 rpm and delivering air at an outlet pressure of 385 kPa. The total-to-total efficiency of the compressor, based upon previous well-established design data, is estimated as 0.82. It can be assumed that the radial component of the air leaving the impeller equals 0.2 times the impeller tip speed. The air enters the inlet axially at a stagnation temperature and pressure of 288 K and 100 kPa. Determine a. the impeller tip speed and tip diameter using the Wiesner slip factor; b. the specific speed of the compressor assuming that the axial velocity at entry is equal to the radial component of velocity at impeller outlet. Comment upon whether the chosen value of the efficiency is appropriate.

How well does the specific speed you have found compare with the values shown in Figure 2.7?

17. For the preceding problem determine the size of the compressor eye given that the air flow is 8 kg/s the radius ratio rh1/rs1 5 0.4. What is the value of the absolute Mach number M1?

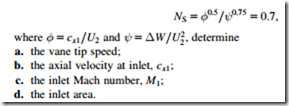

18. A radial-vaned centrifugal compressor is designed for a rotational speed of 2400 rpm and requires 1 MW of power to compress the incoming air at a flow rate of 8 kg/s. The air enters the intake axially and the stagnation conditions are 103 kPa and 288 K. Assuming the slip factor is 0.9 and the specific speed

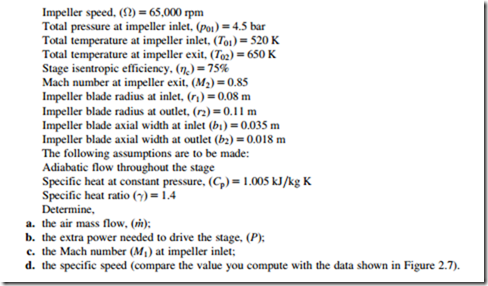

19. The final stage of a high-pressure axial compressor is centrifugal of the purely radial type (see Figure 7.5), the flow at all points through the stage having no axial component. At the design point for the stage the following data applies:

19. The final stage of a high-pressure axial compressor is centrifugal of the purely radial type (see Figure 7.5), the flow at all points through the stage having no axial component. At the design point for the stage the following data applies:

Related posts:

Incoming search terms:

- numericals on centrifugal compressor

- centrifugal compressor numericals

- solved problems on centrifugal compressors

- for pump and compressor pipes mail

- numerical on centrifugal compressor

- Compressors and Pumps mail

- Centrifugal compressors mail

- problems on centrifugal compressor

- centifugal air compressor static and stagnation

- Compressors High Pressure Water Pumps mail

- in a centrifugal compressor the air enters the impeller axially and leaves the vane radially

- 366m/s centrifugal compressor mach no is

- numerical on centrifugal compressor in design of pump compressor and blower be mechanical

- mach number problems on centrifugal pump

- numerical of centrifugal comp

- Low pressure Industrial Centrifugal Fan mail

- how to solve numerical based on centrifugal compressor

- numericals based on centrifugal compressor

- stagnation value in centrifugal compressor

- solved problems on centrifugal compressors with hints

- Radial Fans mail

- Pumps Centrifugal mail

- numerical problem on centrifugal fan

- problems based on crntrifugal compressor

- numericals to determine power to drive the centrifugal fan

- numericals s on fan

- water enters impeller centrifugal compressor

- how to solve centrifugal compressor numericals

- difficult numericals problems on centrifugal compressor

- centrifugal compresser numericals

- centrifugal air compressor numericals

- can centrifugal compressor give 100 m/s speed

- Backward Curved SWSI Centrifugal Fan mail

- Absolute Machinery mail

- a centrifugal pump is used to raise water against a staic head of 18 0

- A centrifugal compressor has an impeller tip speed of 366 m/s Determine the absolute Mach number of the flow leaving the radial vanes of the impeller when the radial component of velocity at impeller exit is 30 5 m/s and the slip factor is 0 90 Given that

- 86 Centrifugal Water Pump Agriculture Machinery Equipment mail

- centrifugal compresser solved numericals

- centrifugal compressor design numerical problems

- Compressors pumps mail

- Centrifugal fan mail

- centrifugal compressors problems

- centrifugal compressors numerical problems

- centrifugal compressors in pronlems

- centrifugal compressor solved problems

- centrifugal compressor inlet diameter 300 and exit diameter 600 air inlet in compressor 15 m/s

- centrifugal compressor example problems

- 3 A centrifugal compressor has an impeller tip speed of 366 m/s Determine the absolute Mach number of the flow leaving the radial vanes of the impeller when the radial component of velocity at impeller exit is 30 5 m/s and the slip factor is 0 90 Given th