PROBLEMS

1. A fan operating at 1750 rpm at a volume flow rate of 4.25 m3/s develops a head of 153 mm measured on a water-filled U-tube manometer. It is required to build a larger, geometrically similar fan that will deliver the same head at the same efficiency as the existing fan but at a speed of 1440 rpm. Calculate the volume flow rate of the larger fan.

2. An axial flow fan 1.83 m diameter is designed to run at a speed of 1400 rpm with an average axial air velocity of 12.2 m/s. A quarter scale model has been built to obtain a check on the design and the rotational speed of the model fan is 4200 rpm. Determine the axial air velocity of the model so that dynamical similarity with the full-scale fan is preserved. The effects of Reynolds number change may be neglected. A sufficiently large pressure vessel becomes available in which the complete model can be placed and tested under conditions of complete similarity. The viscosity of the air is independent of pressure and the temperature is maintained constant. At what pressure must the model be tested?

3. The water pump used to generate the plot shown in Figure 2.2 has an impeller diameter of 56 mm. When tested at a speed of 4500 rpm, the head-volume flow rate characteristic produced can be approximated by the equation

where H is in meters and Q in dm3/s. Show that, provided viscous and cavitation effects are negligible, the characteristic of all geometrically similar pumps may be written in dimensionless form as

where ψ is the dimensionless head coefficient, gH/Ω2D2, Φ is the flow coefficient, Q/ΩD3, and Ω is expressed in rad/s. Show that this result is consistent with Figure 2.2, where Ω is expressed in rev/s.

4. A water turbine is to be designed to produce 27 MW when running at 93.7 rpm under a head of 16.5 m. A model turbine with an output of 37.5 kW is to be tested under dynamically similar conditions with a head of 4.9 m. Calculate the model speed and scale ratio. Assuming a model efficiency of 88%, estimate the volume flow rate through the model. It is estimated that the force on the thrust bearing of the full-size machine will be 7.0 GN. For what thrust must the model bearing be designed?

5. Derive the nondimensional groups that are normally used in the testing of gas turbines and compressors. A compressor has been designed for normal atmospheric conditions (101.3 kPa and 15oC). To economize on the power required, it is being tested with a throttle in the entry duct to reduce the entry pressure. The characteristic curve for its normal design speed of 4000 rpm is being obtained on a day when the ambient temperature is 20oC. At what speed should the compressor be run? At the point on the characteristic curve at which the mass flow would normally be 58 kg/s, the entry pressure is 55 kPa. Calculate the mass flow rate during the test.

6. Describe, with the aid of sketches, the relationship between geometry and specific speed for pumps.

a. A model centrifugal pump with an impeller diameter of 20 cm is designed to rotate at 1450 rpm and to deliver 20 dm3/s of freshwater against a pressure of 150 kPa. Determine the specific speed and diameter of the pump. How much power is needed to drive the pump if its efficiency is 82%?

b. A prototype pump with an impeller diameter of 0.8 m is to be tested at 725 rpm under dynamically similar conditions as the model. Determine the head of water the pump must overcome, the volume flow rate, and the power needed to drive the pump.

7. A hydraulic turbine is to be installed where the net head is 120 m and the normal available flow rate is 1.5 m3/s. A 48 pole synchronous generator is available (to operate with a 60 Hz electrical system) and has an adequate power capacity matching the turbine. Determine

a. the rotational speed and the electrical power that can be delivered if the system efficiency (turbine and generator) is 85%;

b. the power specific speed of the turbine;

What type of turbine is being used in this application?

8. A hydraulic turbine running at 160 rpm, discharges 11 m3/s and develops 2400 kW at a net head of 25 m. Determine

a. the efficiency of the turbine;

b. the speed, flow rate, and power output of this turbine when running under a net head of 40 m assuming homologous conditions and the same efficiency.

9. A hydraulics engineer is planning to utilize the water flowing in a stream, normally able to provide water at a flow rate of 2.7 m3/s, and a head of 13 m for power generation. The engineer is planning to use a 2.0 m diameter turbine operating at a rotational speed of 360 rpm and at a hoped for efficiency of 88%.

a. Determine the likely power developed by the turbine, the specific speed and specific diameter, and the most suitable type of turbine for this duty.

b. The engineer then decides, first of all, to test a geometrically similar model turbine with a diameter of 0.5 m (operating at the same specific speed and specific diameter as the prototype) and with a head of 4.0 m. Determine, for the model, the volume flow rate, the rotational speed, and the power.

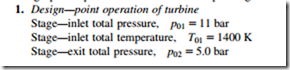

10. A single-stage axial flow gas turbine is to be tested in a “cold rig” so as to simulate the design-point operation. The two sets of operating conditions are:

For both sets of conditions, assume that the axial velocity across the stage remains constant.

Determine

a. the stage—exit total temperature T02ðcrÞ;

b. the power output in the cold rig.

Assume that the average specific heat ratio for both operating conditions is given by γ 5 1:36.

plz provide the answers