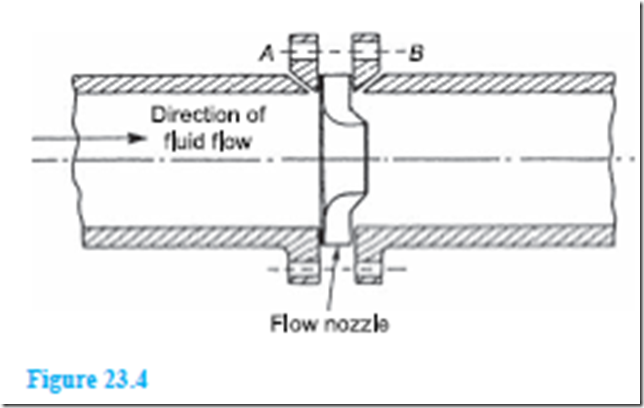

Flow nozzle

The flow nozzle lies between an orifice plate and the venturimeter both in performance and cost. A typical section through a flow nozzle is shown in Figure 23.4, where pressure tappings are located immediately adjacent to the upstream and downstream faces of the nozzle (i.e. at points A and B). The fluid flow does not contract any further as it leaves the nozzle and the pressure loss created is considerably less than that occurring with orifice plates. Flow nozzles are suitable for use with high velocity flows for they do not suffer the wear that occurs in orifice plate edges during such flows.

Pitot-static tube

A Pitot-static tube is a device for measuring the velocity of moving fluids or of the velocity of bodies moving through fluids. It consists of one tube, called the Pitot tube, with an open end facing the direction of the fluid motion, shown as pipe R in Figure 23.5, and a second tube, called the piezometer tube, with the open- ing at 90° to the fluid flow, shown as T in Figure 23.5. Pressure recorded by a pressure gauge moving with

the flow, i.e. static or stationary relative to the fluid, is called free stream pressure and connecting a pressure gauge to a small hole in the wall of a pipe, such as point T in Figure 23.5, is the easiest method of recording this pressure. The difference in pressure (pR – pT), shown as h in the manometer of Figure 23.5, is an indication of the speed of the fluid in the pipe.

Figure 23.6 shows a practical Pitot-static tube consisting of a pair of concentric tubes. The centre tube is the impact probe that has an open end which faces ‘head-on’ into the flow. The outer tube has a series of holes around its circumference located at right angles to the flow, as shown by A and B in Figure 23.6. The manometer, showing a pressure difference of h, may be calibrated to indicate the velocity of flow directly.

Applications A Pitot-static tube may be used for both turbulent and non-turbulent flow. The tubes can be made very small compared with the size of the pipeline and the monitoring of flow velocity at particular points in the cross-section of a duct can be achieved. The device is generally unsuitable for routine measurements and in industry is often used for making preliminary tests of flow rate in order to specify permanent flow measuring equipment for a pipeline. The main use of Pitot tubes is to measure the velocity of solid bodies moving through fluids, such as the velocity of ships. In these cases, the tube is connected to a Bourdon pressure gauge that can be calibrated to read velocity directly. A development of the Pitot tube, a pitometer, tests the flow of water in water mains and detects leakages.

Advantages of Pitot-static tubes

(i) They are inexpensive devices.

(ii) They are easy to install.

(iii) They produce only a small pressure loss in the tube.

(iv) They do not interrupt the flow.

Disadvantages of Pitot-static tubes

(i) Due to the small pressure difference, they are

only suitable for high velocity fluids.

(ii) They can measure the flow rate only at a particular position in the cross-section of the pipe.

(iii) They easily become blocked when used with fluids carrying particles.

Mechanical flow meters

With mechanical flow meters, a sensing element situated in a pipeline is displaced by the fluid flowing past it. Examples of mechanical flow meters commonly used include:

(a) Deflecting vane flow meter (see Section 23.7)

(b) Turbine type meters (see Section 23.8)

Deflecting vane flow meter

The deflecting vane flow meter consists basically of a pivoted vane suspended in the fluid flow stream as shown in Figure 23.7.

When a jet of fluid impinges on the vane it deflects from its normal position by an amount proportional to the flow rate. The movement of the vane is indicated on a scale that may be calibrated in flow units. This type of meter is normally used for measuring liquid flow rates in open channels or for measuring the velocity of air in ventilation ducts. The main dis- advantages of this device are that it restricts the flow rate and it needs to be recalibrated for fluids of differing densities.