Turbine type meters

Turbine type flow meters are those that use some form of multi-vane rotor and are driven by the fluid being investigated. Three such devices are the cup anemometer, the rotary vane positive displacement meter and the turbine flow meter.

(a) Cup anemometer. An anemometer is an instrument that measures the velocity of moving gases and is most often used for the measurement of wind speed. The cup anemometer has three or four cups of hemispherical shape mounted at the end of arms radiating horizontally from a fixed point. The cup system spins round the vertical axis with a speed approximately proportional to the velocity of the wind. With the aid of a mechanical and/or electrical counter the wind speed can be determined and the device is easily adapted for automatic recording.

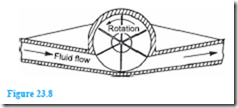

(b) Rotary vane positive displacement meters measure the flow rate by indicating the quantity of liquid flowing through the meter in a given time. A typical such device is shown in section in Figure 23.8 and consists of a cylindrical chamber into which is placed a rotor containing a number of vanes (six in this case). Liquid entering the chamber turns the rotor and a known amount of liquid is trapped and carried round to the outlet. If x is the volume displaced by one blade then for each revolution of the rotor in Figure 23.8 the total volume displaced is 6x. The rotor shaft may be coupled to a mechanical counter and electrical devices which may be calibrated to give flow volume. This type of meter in its various forms is used widely for the measurement of domestic and industrial water consumption, for the accurate measurement of petrol in petrol pumps and for the consumption and batch control measurements in the general process and food industries for measuring flows as varied as solvents, tar and molasses (i.e. thickish treacle).

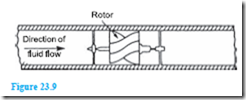

(c) A turbine flowmeter contains in its construction a rotor to which blades are attached which spin at a velocity proportional to the velocity of the fluid which flows through the meter. A typical section through such a meter is shown in Figure 23.9. The number of revolutions made by the turbine blades may be determined by a mechanical or electrical device enabling the flow rate or total flow to be determined. Advantages of turbine flow meters include a compact durable form, high accuracy, wide temperature and pressure capability and good response characteristics. Applications include the volumetric measurement of both crude and refined petroleum products in pipelines up to 600 mm bore, and in the water, power, aerospace, process and food industries, and with modification may be used for natural, industrial and liquid gas measurements. Turbine flow meters require periodic inspection and cleaning of the working parts.

Float and tapered-tube meter

Principle of operation

With orifice plates and venturimeters the area of the opening in the obstruction is fixed and any change in the flow rate produces a corresponding change in pressure. With the float and tapered-tube meter the area of the restriction may be varied so as to maintain a steady pressure differential. A typical meter of this type is shown diagrammatically in Figure 23.10 where a vertical tapered tube contains a ‘float’ that has a density greater than the fluid.

The float in the tapered tube produces a restriction to the fluid flow. The fluid can only pass in the annular area between the float and the walls of the tube. This reduction in area produces an increase in velocity and hence a pressure difference, which causes the float to rise. The greater the flow rate, the greater is the rise in the float position, and vice versa. The position of the float is a measure of the flow rate of the fluid and this is shown on a vertical scale engraved on a transparent tube of plastic or glass. For air, a small sphere is used for the float but for liquids there is a tendency to instability and the float is then designed with vanes that cause it to spin and thus stabilize itself as the liquid flows past. Such meters are often called ‘rotameters’. Calibration of float and tapered tube flowmeters can be achieved using a Pitot-static tube or,

more often, by using a weighing meter in an instrument repair workshop.

Advantages of float and tapered-tube flow meters

(i) They have a very simple design.

(ii) They can be made direct reading.

(iii) They can measure very low flow rates.

Disadvantages of float and tapered-tube flow meters

(i) They are prone to errors, such as those caused by temperature fluctuations.

(ii) They can only be installed vertically in a pipe- line.

(iii) They cannot be used with liquids containing large amounts of solids in suspension.

(iv) They need to be recalibrated for fluids of different densities.

Practical applications of float and tapered-tube meters are found in the medical field, in instrument purging, in mechanical engineering test rigs and in simple process applications, in particular for very low flow rates. Many corrosive fluids can be handled with this device without complications.