Parameters and test methods

There are a large number of cable and material properties which are controlled by the manufacturer in order to ensure fitness for purpose and reliable long-term service performance. However, it is the operating parameters of the finished installed cable which are of most importance to the user in cable selection. The major parameters of interest are as follows:

● current rating

● capacitance

● inductance

● voltage drop

● earth loop impedance

● symmetrical fault capacity

● earth fault capacity

These are dealt with in turn in the following sections.

Current rating

The current rating of each individual type of cable could be measured by subjecting a sample to a controlled environment and by increasing the load current passing through the cable until the steady-state temperature of the limiting cable component reached its maximum permissible continuous level. This would be a very costly way of establishing current ratings for all types of cable in all sizes, in all environments and in all ambient temperatures. Current ratings are therefore obtained using an internationally-accepted calculation method, published in IEC 60287. The formulae and reference material properties presented in IEC 60287 have been validated by correlation with data produced from laboratory experiments.

Current ratings are quoted in manufacturers’ literature and they are listed in IEE Wiring Regulations (BS 7671) for some industrial, commercial and domestic cables. The ratings are quoted for each cable type and size in air, in masonry, direct-in-ground and in underground ducts. Derating factors are given so that these quoted ratings can be adjusted for different environmental conditions, such as ambient temperature, soil resistivity or depth of burial.

Information is given in BS 7671 and in the IEE Guidance Notes on the selection of the appropriate fuse or mcb to protect the cable from overload and fault conditions, and general background is given in sections 8.2 and 8.3.

Capacitance

The capacitance data in manufacturers’ literature is calculated from the cable dimensions and the permittivity of the insulation.

For example, the star capacitance of a 3-core belted armoured cable to BS 6346 is the effective capacitance between a phase conductor and the neutral star point. It is calculated using the following formula:

Equation 9.1 assumes that the conductors are circular in section. For those cables having shaped conductors, the value of capacitance is obtained by multiplying the figure obtained using eqn 9.1 by an empirical factor of 1.08.

The calculated capacitance tends to be conservative, that is the actual capacitance will always be lower than the calculated value. However, if an unusual situation arises in which the cable capacitance is critical, then the manufacturer is able to make a measurement using a capacitance bridge.

If the measured capacitance between cores and between core and armour is quoted, then the star capacitance can be calculated using eqn 9.2:

Inductance

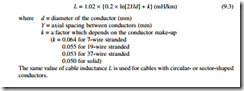

The calculation of cable inductance L for the same example of a 3-core armoured cable to BS 6346 is given by eqn 9.3 as follows:

Voltage drop

BS 7671 specifies that within customer premises the voltage drop in cables is to be a maximum value of 4 per cent. It is therefore necessary to calculate the voltage drop along a cable.

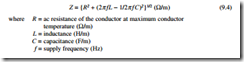

The cable manufacturer calculates voltage drop assuming that the cable will be loaded with the maximum allowable current which results in the maximum allowable operating temperature of the conductor. The cable impedance used for calculating the voltage drop is given by eqn 9.4.

The voltage drop is then given by eqns 9.5 and 9.6: For single-phase circuits:

![]() Symmetrical and earth fault capacity

Symmetrical and earth fault capacity

It is necessary that cables used for power circuits are capable of carrying any fault cur- rents that may flow, without damage to the cable; the requirements are specified in BS 7671. This assessment demands a knowledge of the maximum prospective fault cur- rents on the circuit, the clearance characteristics of the protective device (as explained in Chapter 8) and the fault capacity of the relevant elements in the cable. For most installations it is necessary to establish the let-through energy of the protective device and to compare this with the adiabatic heating capacity of the conductor (in the case of symmetrical and earth faults) or of the steel armour (in the case of earth faults).

The maximum let-through energy (I 2t) of the protective device is explained in Chapter 8. It can be obtained from the protective device manufacturer’s data. In practice the value will be less than that shown by the manufacturer’s information because of the reduction in current during the fault which results from the significant rise in temperature and resistance of the cable conductors.

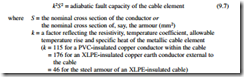

The fault capacity of the cable conductor and armour can be obtained from information given in BS 7671 and the appropriate BS cable standard, as follows:

In practice it will be found that provided the cable rating is at least equal to the nominal rating of the protective device and the maximum fault duration is less than 5 seconds, the conductors and armour of the cables to BS will easily accommodate the let-through energy of the protective device.

It is also important that the impedance of the supply cable is not so high that the protective device takes too long to operate during a zero-sequence earth fault on connected equipment. This is important because of the need to protect any person in contact with the equipment, by limiting the time that the earthed casing of the equip- ment, say, can become energized during an earth fault.

This requirement, which is stated in BS 7671, places restrictions on the length of the cable that can be used on the load side of a protective device, and it therefore demands knowledge of the earth fault loop impedance of the cable. Some cable manufacturers have calculated the earth fault impedance for certain cable types and the data are presented in specialized literature. These calculations take account of the average temperature of each conductor and the reactance of the cable during the fault. The values are supported by independent experimental results. BS 7671 allows the use of such manufacturer’s data or direct measurement of earth fault impedance on a completed installation.