Types of Single-Phase Motors

Such motors, which are designed to operate from a single- phase supply, are manufactured in a large number of types to perform a wide variety of useful services in home, offices, factories, workshops and in business establishments etc. Small motors, particularly in the fractional kilo watt sizes are better known than any other. In fact, most of the new products of the manufacturers of space vehicles, aircrafts, business ma- chines and power tools etc. have been possible due to the advances made in the design of fractional-kilowatt motors. Since the performance requirements of the various applications differ so widely, the motor-manufacturing industry has developed many different types of such motors, each being designed to meet specific demands.

Single-phase motors may be classified as under, depending on their construction and method of starting :

Single-phase motors may be classified as under, depending on their construction and method of starting :

1. Induction Motors (split-phase, capacitor and shaded-pole etc.)

2. Repulsion Motors (sometime called Inductive-Series Motors)

3. A.C. Series Motor

4. Un-excited Synchronous Motors

Single-phase Induction Motor

Constructionally, this motor is, more or less, similar to a polyphase induction motor, except that (i) its stator is provided with a single-phase winding and (ii) a centrifugal switch is used in some types of motors, in order to cut out a winding, used only for starting purposes. It has distributed stator winding and a squirrel-cage rotor. When fed from a single-phase supply, its stator winding produces a flux (or field) which is only alternating i.e. one which alternates along one space axis only. It is not a synchronously revolving (or rotating) flux, as in the case of a two- or a three-phase stator winding, fed from a 2-or 3-phase supply. Now, an alternating or pulsating flux acting on a stationary squirrel-cage rotor cannot produce rotation (only a revolving flux can). That is why a single-phase motor is not self- starting.

However, if the rotor of such a machine is given an initial start by hand (or small motor) or otherwise, in either direction, then immediately a torque arises and the motor accelerates to its final speed (unless the applied torque is too high).

This peculiar behaviour of the motor has been explained in two ways : (i) by two -field or double field revolving theory and (ii) by cross-field theory. Only the first theory will be discussed briefly.

Double-field Revolving Theory

This theory makes use of the idea that an alternating uni-axial quantity can be represented by two oppositely-rotating vectors of half magnitude. Accordingly, an alternating sinusoidal flux can be represented by two revolving fluxes, each equal to half the value of the alternating flux and each rotating synchronously (Ns = 120f/P) in opposite direction*.

As shown in Fig. 36.1 (a), let the alternating flux have a maximum value of Φm. Its component fluxes A and B will each be equal to Φm /2 revolving in anticlockwise and clockwise directions respectively.

zero, as shown in Fig. 36.1 (e) and so on. If we plot the values of resultant flux against q between limits q = 0º to q= 360º, then a curve similar to the one shown in Fig. 36.2 is obtained. That is why an alternating flux can be looked upon as composed of two revolving fluxes, each of half the value and revolving synchronously in opposite directions.

It may be noted that if the slip of the rotor is s with respect to the forward rotating flux (i.e. one which rotates in the same direction as rotor) then its slip with respect to the backward rotating flux is (2 – s)*.

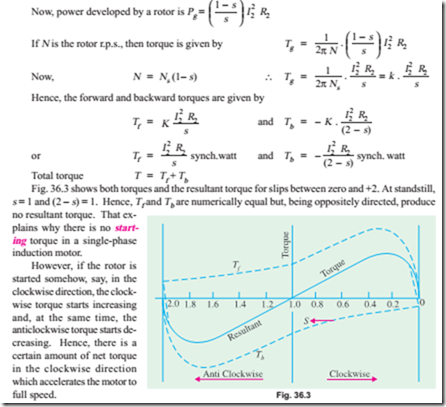

Each of the two component fluxes, while revolving round the stator, cuts the rotor, induces an and this produces its own torque. Obviously, the two torques (called forward and backward torques) are oppositely-directed, so that the net or resultant torques is equal to their difference as shown in Fig. 36.3.