Torque/Speed Curve

The torque developed by a conventional 3-phase motor depends on its speed but the relation between the two cannot be represented by a simple equation. It is easier to show the relationship in the form of a curve (Fig. 34.22). In this diagram, T represents the nominal full-load torque of the motor. As seen, the starting torque (at N = 0) is 1.5 T and the maximum torque (also called breakdown torque) is 2.5 T.

At full-load, the motor runs at a speed of N. When mechanical load increases, motor speed decreases till the motor torque again becomes equal to the load torque. As long as the two torques are in balance, the motor will run at constant (but lower) speed. However, if the load torque exceeds 2.5 T, the motor will suddenly stop.

Shape of Torque/Speed Curve

For a squirrel-cage induction motor (SCIM), shape of its torque/speed curve depends on the voltage and frequency applied to its stator. If f is fixed, T µ V2 (Art 34.22). Also, synchronous speed

depends on the supply frequency. Now, let us see what happens when both stator voltage and frequency are changed. In practice, supply voltage and frequency are varied in the same proportion in order to maintain a constant flux in the air-gap. For example, if voltage is doubled, then frequency is also doubled. Under these conditions, shape of the torque/speed curve remains the same but its position along the X-axis (i.e.speed axis) shifts with frequency.

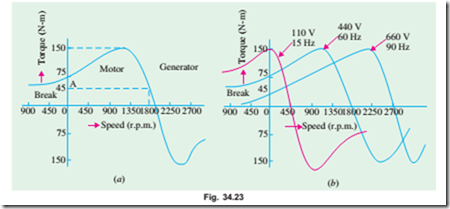

Fig. 34.23 (a) shows the torque/speed curve of an 11.kW, 440-V, 60-Hz 3-f SCIM. As seen, full- load speed is 1728 rpm and full-load torque is 45 N-m (point-A) whereas breakdown torque is 150 N-m and locked-rotor torque is 75 N–m.

Suppose, we now reduce both the voltage and fequency to one-fourth their original values i.e. to 110 V and 15 Hz respectively. As seen in Fig. 34.23 (b), the torque/speed curve shifts to the left. Now, the curve crosses the X-axis at the synchronous speed of 120 ´ 15/4 = 450 rpm (i.e. 1800/4 = 450 rpm). Similarly, if the voltage and frequency are increased by 50% (660 V 90 Hz), the curve shifts to the right and cuts the X-axis at the synchronous speed of 2700 rpm.

Since the shape of the torque/speed curve remains the same at all frequencies, it follows that torque developed by a SCIM is the same whenever slip-speed is the same.

Exampel 34.26. A 440-V, 50-Hz, 4-pole, 3-phase SCIM develops a torque of 100 N-m at a speed of 1200 rpm. If the stator supply frequency is reduced by half, calculate

(a) the stator supply voltage required for maintaining the same flux in the machine.

(b) the new speed at a torque of 100 N-m.

Solution. (a) The stator voltage must be reduced in proportion to the frequency. Hence, it should also be reduced by half to 440/2 = 220 V.

(b) Synchronous speed at 50 Hz frequency = 120 ´ 50/4 = 1500 rpm. Hence, slip speed for a torque of 100 N-m = 1500 – 1200 = 300 rpm.

Now, synchronous speed at 25 Hz = 1500/2 = 750 rpm.

Since slip-speed has to be the same for the same torque irrespective of the frequency, the new speed at 100 N-m is = 750 + 300 = 1050 rpm.