Recordable DVD

The original DVD specification related to the read-only (non-Recordable) DVD-ROM explained in chapter 21. Recording on a DVD requires a blank disc capable of being written on. Today, there are several competing recordable formats for DVD applications. They fall into two groups:

● Recordable (write once) format: DVD-R and DVD + R, R for recordable and

● Re-writable or re-recordable (write several times) format: DVD-RAM, DVD-RW and DVD +RW.

DVD-R, DVD-RW and DVD-RAM formats are supported by Panasonic, Toshiba, Apple Computer, Hitachi, NEC, Pioneer, Samsung and Sharp. They are also supported by the DVD Forum. DVD+R and DVD+RW for- mats on the other hand are supported by Philips, Sony, Hewlett-Packard, Dell, Ricoh, Yamaha and others.

The various recording formats have different features: DVD-R is com- patible with over 80% of all DVD players and DVD-ROM drives. DVD- RW was the first DVD recording format released that is compatible with almost 70% of all DVD players and DVD-ROM drives. It supports single side 4.7 GB and double-side 9.4 GB disc capacities. DVD +R is compatible with over 80% of all DVD players and DVD-ROM drives. DVD+RW has better features than DVD-R such as lossless linking and both constant angular velocity (CAV) and constant linear velocity (CLV) writing. Its greatest advantage is that it is compatible with almost all DVD players and DVD-ROM drives. It supports single-side 4.7 GB and double-side 9.4 GB disc capacities. DVD-RAM has the best recording features but unfortunately it is incompatible with most DVD players and DVD-ROM drives. DVD-RAM discs are used more as a removable storage device than a recording medium for audio/video information.

Dual layer (or double-layer) technology is supported by a range of manufacturers including Dell, HP, Verbatim, Philips, Sony, Yamaha and others. Also known as DVD + R DL or DVD-R DL, they provide two indi- vidual recordable layers on a single-sided DVD disc. They have a capacity of 8 GB and normally referred to as DVD-R9.

There are two versions of DVD-R format: DVD-R(G) for General and the DVD-R(A) for Authoring. It is also possible to create a hybrid disc which is partially read only and partially recordable, sometimes known as DVD-PROM. This would normally be a disc with two layers, one of which is a read only and the other a recordable part.

While DVD-ROM disc such as a DVD-video disc have pits stamped permanently onto its surface, writable or recordable discs use other tech- niques to produce the same effect of a pit. In the case of a write-once DVD discs, a photosensitive dye is used to cover a reflective metallic surface. When the dye is heated by a high-power (6–12 mW) pulsating laser beam, it becomes darker and hence less transparent resulting in a weaker reflec- tion. A pulsating laser is necessary to avoid overheating the dye creat- ing oversized ‘pits’. The disc is manufactured with a wobbled groove which is moulded into the substrate. The wobbled groove provides a self-regulating clock to guide the laser beam as it burns the disc. The wobbled track is pre-divided into sectors and each sector is identified by pre-stamped header. DVD-R is available in two versions. Version 1 has a

capacity of 3.95 billion bytes (3.68 GB) and version 2 has a capacity of 4.7 billion bytes (4.37 GB).

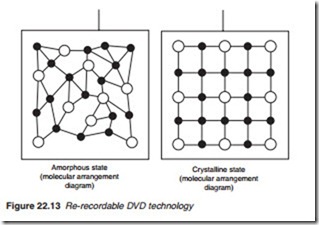

Re-writable DVD discs including DVD-RAM employ a different tech- nology, known as phase-change. Phase-change technology uses a metal compound that changes its reflectivity as it moves between a crystallised and an amorphous state (Figure 22.13). When the compound is heated by a low-power laser, it melts creating a crystallised spot with a high reflec- tivity known as ‘eraser’. Alternatively, if it is heated by a high-power laser, it melts and then cools down rapidly to form an amorphous (non- crystalline) spot of low reflectivity, known as ‘mark’. The marks can be read by a low power laser to retrieve the data from the disc. Phase-change uses the same wobbled groove as DVD-ROM, but it writes its data bits in both the groove and the land between the grooves as shown in Figure

22.14. The purpose of the wobbled grove is twofold:

● The generation of a spindle motor control signal

● The generation of a gate signal used in detection of the land pre-pits The pre-pits on the other hand ensures high precision when writing the data and it provides the recording address and other information that are necessary for writing on a DVD disc.