Nonimpact Printing Technologies

Ink Jet

The transfer process of ink jet printing is one of removing a drop of liquid ink from the bulk and giving it a velocity of sufficient precision and magnitude to place it on a substrate in close proximity to but not touching the printhead. There are three broad techniques: continuous, electrostatic, and drop on demand. Continuous ink jet printing, because of its intrinsic high drop rate, has tended to find more applications in commercial systems; electrostatic methods have yet to find widespread application, but have been used for facsimile recording; drop on demand, because of its simplicity and ease of implementation of color, has been widely accepted in the office and home market.

Continuous Ink Jet

The basic principle of continuous ink jet is to take advantage of the natural breakup process due to an instability in the jet that is formed when fluid is forced under pressure through a small orifice. This results from the interplay of surface tension and viscosity and takes place in a quasirandom manner unless external stimulation is applied. This breakup process was first studied by Rayleigh who characterized it via a growth rate for the instability, which depended on the jet diameter D, its velocity V , and the frequency F of any external stimulation. Rayleigh showed that the frequency for maximum growth rate of the instability was

F = V/4.5D. By stimulating the jet at this frequency it is possible to obtain a uniform stream of droplets. The typical method of providing this stimulation today is via a piezoelectric transducer as an integral part of the printhead.

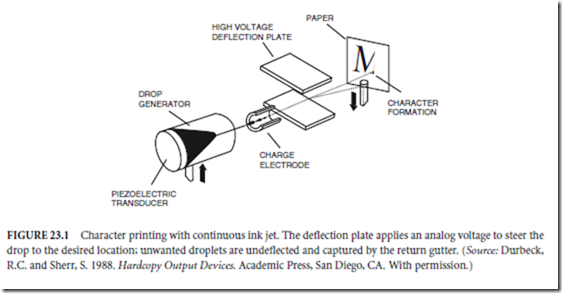

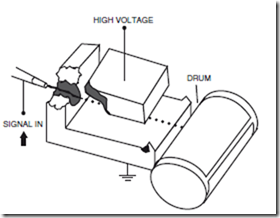

To make use of these droplets for printing it is necessary to charge them at breakoff. This is accomplished by placing electrodes in proximity to the breakup region of the jet. Deflection voltages are then applied farther downstream to direct the droplet to the substrate or into a collector for re- circulation and reuse. The earliest techniques in- volved charging the droplet and applying a variable deflection field to direct it to a specific spot on the paper, enabling full height characters to be printed in one pass (see Fig. 23.1). Later methods focused on producing a stream of charged droplets and using the printing (high-voltage) electrode to deflect unwanted drops for recirculation and reuse (Fig. 23.2). This technique, known as binary charged continuous ink jet, lends itself to the construction of multiple nozzle arrays, and there are a number of page-wide implementations in use.

Binary charged continuous ink jet with its high droplet rate makes a simple gray scaling technique possible. The dot on the paper is modulated in size by printing from one up to N droplets at the same location, where N is the number of different dot sizes desired. By operating at high frequencies and small drop volumes it is possible to produce sufficient gray levels such that full grayscale printing is achieved at reasonable print speeds. The most recent implementation of this method offers 512 gray levels at addressabilities between 200–300 pixels/in. To achieve the small fundamental droplet size, typical implementations employ glass capillaries with diameters of the order of 10 µm and are pressurized from 500–700 lb/in2. A color printhead will contain four capillaries, one for each color ink plus black.

FIGURE 23.2 Binary charged continuous ink jet. Droplets, charged at breakoff, are directed to the paper on a rotating drum. Droplets not selected for printing are diverted by the high-voltage electrode to be collected by a return gutter. (Source: Durbeck, R.C. and Sherr, S. 1988. Hardcopy Output Devices. Academic Press, San Diego, CA. With permission.

Drop On Demand (DOD) Ink Jet

For office and home applications the complexities of continuous ink jet technology, such as startup and shutdown procedures, ink recirculation, and the limited nozzle count, have led to the development of drop on demand ink jet technology. These devices employ unpressurized ink delivery systems and, as implied by their name, supply a drop only when requested. The basic technique employed is to produce a volume change in either the ink supply channel or an ink chamber adjacent to the nozzle such that the resulting pressure wave causes drop ejection. Refill is achieved by capillary forces and most DOD systems operate with a slight negative pressure at the ink reservoir. The mechanism for generating the pressure wave dominates the design of these devices, and there are two techniques extant in common DOD printers. One employs the pressure pulse derived from the vaporization of superheated fluid, and the other makes use of piezoelectric materials, which can be deformed by the application of electric potentials.

Devices employing the vaporization of superheated fluid are known concurrently as thermal ink jet or bubble jet printers, the choice of name depending on the manufacturer. Since drop on demand ink jets rely on capillary refill, their operational frequencies are much lower than for continuous ink jet devices. This stresses the importance of the compactness of the actuating system so as to achieve reasonable printing speeds via multiple nozzle printheads. The nozzles must also be precisely registered with respect to each other if systematic print artifacts are to be avoided.

FIGURE 23.3 Drop ejection sequence for thermal ink jet. Nominal time frames and values for various parameters are given to indicate the scale of the three processes of nucleation, bubble growth, and jet formation followed by drop ejection and refill.

Thermal Ink Jet/Bubble Jet DOD Printers

When fluids are heated at extreme rates (e.g., 500 × 106 W/m2), they enter a short-lived metastable state where temperatures can far exceed the boiling point at atmospheric pressure. The difference between the elevated temperature and the boiling point is known as the degree of superheat. This process does not continue indefinitely, and all fluids have what is known as a superheat limit. At this point nucleation and vaporization will occur in the bulk of the fluid. These devices employ an electrically driven planar heater (typically, 50–60 µm2) in contact with the fluid. Under these conditions vaporization commences at the surface of the heater due to the presence of nucleation sites such as microscopic roughness. With correctly chosen heating rates this can be made very reliable. These heating rates lead to electrical pulse widths of 3–5 µs. In this time frame only a submicron portion of the fluid will be superheated. The net result is a vaporization pulse well in excess of atmospheric pressure and of approximately 3/4-µs duration. By locating a nozzle directly over or alongside the resistor this pressure pulse will eject a droplet (Fig. 23.3).

Within limits of the drop volume desired, it is found that the linear dimensions of the nozzle diameter and planar resistor are comparable. The actuator is therefore optimally compact, and this enables high- nozzle count printheads. The fabrication of the resistors is accomplished by photolithographic techniques common to the IC industry and the resistor substrates are silicon with a thin layer of insulating silicon dioxide. Precise registration from nozzle to nozzle is guaranteed under these circumstances, and electrical drive circuits may be integrated into the head to provide multiplexing capability. This is a valuable attribute for scanning printheads, which employ a flexible printed circuit for interconnect. These features have produced printheads currently numbering 300 or more nozzles for a single color. An additional benefit of the compactness of this technology is that the ink supply can be fully integrated with the print- head. This provides the user with virtually maintenance free operation as the printhead is replaced when the ink supply is consumed. Since the majority of problems arise from paper dust particles finding their way into a nozzle and occasionally becoming lodged there, printhead replacement provides for user service at reasonable cost. Some implementations feature a semipermanent printhead, which is supplied by ink from replaceable cartridges. The design choice is then a tradeoff involving many factors: frequency of maintenance, cost of operation, how often the printer is to be used, type of material printed, etc. The important subject of ink and paper for these printers will be taken up at the end of the section on DOD technologies.

FIGURE 23.4 Squeeze tube piezoelectric ink jet. Early implementation of piezoelectric transducers for drop ejection. (Source: Advanced Technology Resources Corporation.)

FIGURE 23.4 Squeeze tube piezoelectric ink jet. Early implementation of piezoelectric transducers for drop ejection. (Source: Advanced Technology Resources Corporation.)

Piezoelectric DOD Printers

Crystalline structures, which develop a spontaneous dipole moment when mechanically strained, thereby distorting their crystal structures, are called piezoelectric. These materials may conversely be caused to be distorted via electrical potentials applied to the appropriate planes of the cyrstal. Piezoceramics have a polarization direction established during the manufacturing process, and the applied fields then interact with this internal polarization to produce mechanical displacement. Depending on the direction of the applied fields, the material can compress or extend longitudinally or transversely. These materials have found widespread use as transducers for DOD printers. An early form was that of a sleeve over a glass capillary, which terminated in a nozzle (Fig. 23.4). Depending on the location of the electrodes either a radial or longitudinal compression could be applied leading to a pressure wave in the enclosed ink sufficient to eject a droplet. Using the diameter of the nozzle as a unit of linear dimension, this approach placed the transducer well upstream from the nozzle (Fig. 23.5). Implementation of this design in a multinozzle printhead required careful matching of transducers and fluid impedance of the individual channels feeding each nozzle. This was a challenging task, and most designs bond a planar transducer to an ink chamber adjacent to a nozzle, as shown in Fig. 23.6.

FIGURE 23.5 Drop ejection sequence for piezoelectric printhead. Schematic of drop ejection via deflection of piezocrystal bonded to an ink capillary. In practice the piezodrivers were located well upstream of the nozzle due their size. (Source: Advanced Technology Resources Corporation.)

FIGURE 23.6 Design of Stemme Larson electric-driven DOD ink jet. Note the direct coupling of the pressure pulse to the ink chamber at the nozzle. (Source: Advanced Technology Resources Corporation.)

The method of directly coupling the piezoelectric transducer through an ink chamber to an exit nozzle has seen many enhancements and developments since its invention. A feature of some designs is that of air flow channeled at the orifice in such a way as to entrain the droplet as it exits the nozzle and to improve its directional stability, as well as to accelerate the droplet. This enables the device to be operated at lower transducer deflections and, therefore, at higher droplet rate since the settling time of the device has been reduced. Piezodevices can operate at elevated temperatures and are used to eject inks that are solid at room temperature. For solid inks the material is melted to a design temperature for appropriate viscosity and surface tension and then supplied to the piezoelectric-driven ink chamber. The ink then solidifies instantly on contact with the substrate.

A more recent innovation employs piezoelectric transducers operated in the longitudinal mode. The transducers are formed from a single block of piezoceramic material in the form of an array of rods. Suitably placed potentials excite the rods to extend in the longitudinal direction. By bonding one end of the rod in contact with a thin membrane forming the base of an ink chamber, a pressure pulse is generated similar to that of the previous design (Fig. 23.7). To achieve sufficient pressure amplitude a diaphragm is used that is substantially larger than the orifice exit diameter. The consequence of this is that high nozzle

density printheads will require multiple rows of nozzles (Fig. 23.8). This design has been implemented to date with liquid inks only.

Grayscale Methods for DOD Ink Jet Printers

The drop rates for DOD devices are typically an order of magnitude less than those of continuous, pressurized systems. This dictates different strategies for the achievement of grayscale. Techniques are based on the generation of a few gray levels that, when incorporated into digital halftoning algorithms, such as error diffusion, clustered, dispersed dot, or blue-noise dither, produce a satisfactory grayscale. The number of levels necessary, their position relative to the maximum modulation achievable (i.e., maximum dot size or maximum intensity), and the specialized techniques employed in digital halftoning are an area of active research. There are many patents in the literature governing these techniques, and manufacturers seek to distinguish their devices by the technique offered. When combined with resolution enhancement methods mentioned in the section on print quality, printers with medium resolution, such as 300 dpi and 2 bits of grayscale, can produce remarkable results for both images, text, and graphics.

There are several methods available for DOD devices to modulate either the size or intensity of the dot. For piezodevices, pulse width modulation has been shown to produce droplets of different volumes and, therefore, dot sizes. All DOD ink jet devices have the option of ejecting a droplet repeatedly at the same location by passing over the same swath as many times as desired but this will affect throughput rates. Printheads with sufficient nozzle count can do this and still keep throughput rates within reason. For vapor bubble driven devices, a unique option exits by virtue of the short duration of the actuating bubble. Typical lifetime of bubbles in these devices, from vaporization through to bubble collapse, is of the order of 20 µs. If the resistor is pulsed shortly after bubble collapse, a second droplet can be ejected virtually on the tail of the initial droplet. This technique has been called multidrop in the literature. The ink chamber is fired under partial refill conditions, but with proper design several droplets can be ejected by this method at drop rates at around 40 kHz and having substantially the same volume (Fig. 23.9). These merge on the substrate to produce different dot sizes according to the number of droplets ejected for the location. This is not an option for most piezodevices due to the slower settling time of the actuator. Dye dilution methods have also been demonstrated as a way of modulating the intensity of the dot. If no halftone algorithm is employed, this will require many sets of nozzles to accommodate the different dye dilutions.

FIGURE 23.9 Stylized representation of multidrop process. Each input pulse consists of a group of drive pulses chosen for the final dot size desired. (Source: Durbeck, R.C. and Sherr, S. 1988. Hardcopy Output Devices. Academic Press, San Diego, CA. With permission.)

Ink and Paper for Ink Jet Devices

When liquid inks are employed the paper properties have a major impact on the print quality. The ink droplets will be absorbed by a substrate whose internal structure and surface energy will determine the size, shape, and overall microstructure of the drop. Paper, being a interlocking mesh of cellulose fibers with sizing and binding chemistry, is quite variable in nature. Figure 23.10 is a schematic indication of the response of paper to different volumes of ink. Note that it can be very nonlinear at low drop volumes and either flat or high gain at large volumes. The implication is that by simply changing the paper the print quality is altered. To control this variablity some papers are given a thin coat of claylike material containing whiteners, which are often fluorescent.

This coating presents a microporous structure that is more uniform than the cellulose fibers.

Dot formation on coated papers is therefore circular and more stable than on uncoated stock. Un-coated papers allow the ink to wick down the fibers producing an effect known as feathering of the dot. In this case, microscopic tendrils of dye appear at the edge of the dot giving it and the overall print quality a blurred effect. This is particularly serious in the case of text printing, which benefits most fromsharp dot edges. Feathering is common for papers used in xerographic copiers. Bond paper, which is a popular office stock, is a partially coated paper and exhibits little feathering.

FIGURE 23.10 Paper response curves. The lower curve is typical of coated stock, which minimizes dot spread. (Source: Durbeck, R.C. and Sherr, S. 1988. Hardcopy Out- put Devices. Academic Press, San Diego, CA. With per- mission.)

Depending on the manufacturer, several techniques are employed to minimize the impact of paper variability on print quality. One method, the use of a heater, takes advantage of the fact that absorption into the paper does not commence immediately upon contact. There is a period known as the wetting time, which can be as long as 80 µs during which no absorption takes place. The application of heat immediately in the vicinity of the printhead swath can effectively “freeze the dot” by vaporizing carrier. This makes the printer insensitive to change in paper stock and provides uniformly high print quality regardless of substrate. Other methods make use of altering the fluid chemistry by means of surfactants, which increase penetration rate, and high vapor pressure additives to increase removal of fluid into the atmosphere. If the ink penetrates quickly then it is less likely to spread sideways and, thereby, dot size variation is lessened. When choosing a drop on demand ink jet printer, it is advisable to test the performance over the range of paper stocks to be used. In some cases it will be found that high-quality printing can only be obtained when a paper specified by the manufacturer is chosen.

With reference to the section on print quality, it should be kept in mind that the choice of paper will affect the overall dynamic range of print. Text printing, to be pleasing, needs to have an optical density of at least 1.3–1.4. For images, the more dynamic range the better, and special coated stock will always excel over copy paper if image quality is important. Many of the coated papers available still have a matte surface that diffusely reflects the light and limits the dynamic range for reasons previously discussed. Some manufacturers now offer a high-gloss substrate specifically intended for images. These substrates have a plastic base with special coatings to absorb the ink through to the substrate leaving a high gloss finish. This greatly improves the dynamic range to the point of approximating that of photographic paper. These substrates provide ink jet printers with the capability to produce highly saturated brilliant colors with exceptional chromatic and dynamic range and should be used if image printing is the primary objective. Besides excellent print quality there are other demands placed on the ink. It must provide reliable operation of the device and a durable image. By this it is meant that the image does not fade rapidly, that it is mechanically sound, that it cannot be easily removed from the paper, and that it is impervious to liquids. For liquid ink, this is a challenge since solvent-based color highlighter pens are commonly used to mark up printed documents. These solvents can cause the ink to smear depend- ing on the choice of ink chemistry and the manner in which the colorants are fixed to the substrate. These issues focus on colorant chemistry, and much research is applied to this problem. There are fade-proof dyes, but many are either incompatible with the ink vehicle, typically water, or are toxic or

mutagenic.