Design point efficiency of a turbine stage

In this section, the performance of a turbine stage in terms of its efficiency is calculated for several types of design, i.e., 50% reaction, zero reaction, and zero exit flow angle, using the loss correlation method of Soderberg described in Chapter 3. The results are most usefully presented in the form of carpet plots of the stage loading coefficient, ψ, and flow coefficient, φ.

Total-to-total efficiency of 50% reaction stage

In a multistage turbine the total-to-total efficiency is the relevant performance criterion, the kinetic energy at stage exit being recovered in the next stage. After the last stage of a multistage turbine or

From these expressions combined with Soderberg’s correlation given in Eq. (3.46), the performance chart, shown in Figure 4.14, was derived for specified values of ψ and φ. From this chart it can be seen that the peak total-to-total efficiency, ηtt, is obtained at very low values of φ and ψ. As

indicated in a survey by Kacker and Okapuu (1982), most aircraft gas turbine designs operate with flow coefficients in the range, 0.5 # φ # 1.5, and values of stage loading coefficient in the range, 0.8 # ψ # 2.8.

Total-to-total efficiency of a zero reaction stage

The degree of reaction will normally vary along the length of the blade depending upon the type of design specified. The performance for R 5 0 represents a limit, lower values of reaction are possible but undesirable as they would give rise to large losses in efficiency. For R , 0, w3 , w2, which means the relative flow decelerates across the rotor.

The performance chart shown in Figure 4.15 was derived using these expressions. This is similar in its general form to Figure 4.14 for a 50% reaction, with the highest efficiencies being obtained at the lowest values of φ and ψ, except that higher efficiencies are obtained at higher values of the stage loading but at reduced values of the flow coefficient.

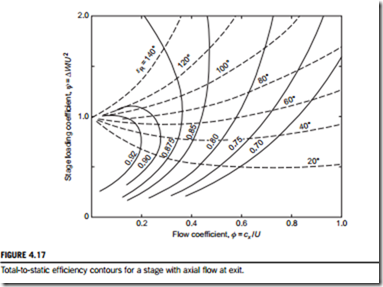

Total-to-static efficiency of stage with axial velocity at exit

A single-stage axial turbine will have axial flow at exit and the most appropriate efficiency is usually total to static. To calculate the performance, Eq. (4.21) is used: