Introduction

Utility companies make a good-faith attempt to deliver clean, well-regulated power to their customers. Most disturbances on the ac line are beyond the control of the utility company. Large load changes imposed by customers on a random basis, PF correction switching, lightning, and accident-related system faults all com- bine to produce an environment in which tight control over ac power quality is difficult to maintain. There- fore, the responsibility for ensuring ac power quality must rest with the users of sensitive equipment.

The selection of a protection method for a given facility is as much an economic question as it is a technical one. A wide range of power-line conditioning and isolation equipment is available. A logical decision about how to proceed can be made only with accurate, documented data on the types of disturbances typically found on the ac power service to the facility. The protection equipment chosen must be matched to the problems that exist on the line. Using inexpensive basic protectors may not be much better than operating directly from the ac line. Conversely, the use of a sophisticated protector designed to shield the plant from every conceivable power disturbance may not be economically justifiable.

Purchasing transient-suppression equipment is only one element in the selection equation. Consider the costs associated with site preparation, installation, and maintenance. Also consider the operating efficiency of the system. Protection units that are placed in series with the load consume a certain amount of power and, therefore, generate heat. These considerations may not be significant, but they should be taken into account. Prepare a complete life-cycle cost analysis of the protection methods proposed. The study may reveal that the long-term operating expense of one system outweighs the lower purchase price of another.

The amount of money a facility manager is willing to spend on protection from utility company disturbances generally depends on the engineering budget and how much the plant has to lose. Spending $250,000 on systemwide protection for a highly computerized manufacturing center is easily justified. At smaller operations, justification may not be so easy.

The Key Tolerance Envelope

The susceptibility of electronic equipment to failure because of disturbances on the ac power line has been studied by many organizations. The benchmark study was conducted by the Naval Facilities Engineering Command (Washington, DC). The far-reaching program, directed from 1968 to 1978 by Lt. Thomas Key, identified three distinct categories of recurring disturbances on utility company power systems. As shown in Table 11.1, it is not the magnitude of the voltage, but the duration of the disturbance that determines the classification.

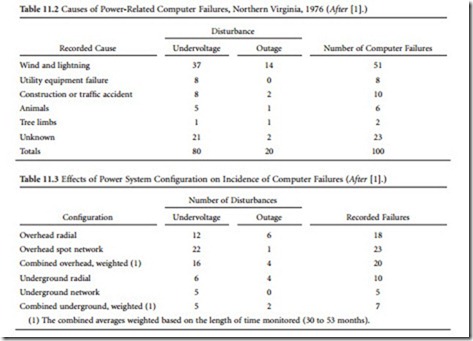

In the study, Key found that most data processing (DP) equipment failure caused by ac line disturbances occurred during bad weather, as shown in Table 11.2. According to a report on the findings, the incidence of thunderstorms in an area can be used to predict the number of failures. The type of power- transmission system used by the utility company also was found to affect the number of disturbances observed on power company lines (Table 11.3). For example, an analysis of utility system problems in Wash- ington, DC , Norfolk, VA, and Charleston, SC, demonstrated that underground power-distribution systems experienced one-third fewer failures than overhead lines in the same areas. Based on his research, Key developed the “recommended voltage tolerance envelope” shown in Figure 11.1. The design goals illustrated are recommendations to computer manufacturers for implementation in new equipment.