Pressure

There are four types of pressure measurement. Differential pressure is the difference between two pressures applied to the transducer. Gauge pressure is made with respect to atmospheric pressure. It can be considered as a differential pressure measurement with the low pressure leg left open, and is usually denoted by the suffix ‘g’ (e.g. 37 psig). Most pressure transducers in hydraulic and pneumatic systems indicate gauge pressure. Absolute pressure is made with respect to a vacuum, so

Absolute pressure = gauge pressure + atmospheric pressure (4.1)

Atmospheric pressure is approximately 1 bar, 100 kPa or 14.7 psi.

Head pressure is used in liquid level measurement and refers to pressure in terms of the height of a liquid (e.g. inches water gauge). It is effectively a gauge pressure measurement, as in a vented vessel any changes in atmospheric pressure will affect both legs of the transducer equally giving a reading which is directly related to the liquid height. The head pressure is given by:

P = ρgh (4.2)

where P is the pressure in pascals, ρ is the density (kg m–2), g is the acceleration due to gravity (9.8 ms–2) and h is the column height in metres.

The manometer

Manometers give a useful insight into the principle of pressure measurement. If a U-tube is part filled with liquid, and differing pressures are applied to both legs (Fig. 4.5), the liquid will fall on the high pressure side and rise on the low pressure side until the

head pressure of the liquid matches the pressure difference. If the two levels are separated by a height h then

where P1 and P2 are the pressures (in pascals) and ρ and g are as in eqn 4.2.

Elastic sensing elements

The Bourdon tube is the most common pressure indicating device. The tube is made by flattening a circular cross section tube to the section shown in Fig. 4.6 and bending it into a C-shape. One end is fixed and connected to the pressure to be measured. The other end is closed and left free. If pressure is applied to the tube it will tend to straighten, causing the free end to move up and to the right. This motion is converted to a circular motion for a pointer with a quadrant and pinion linkage. A Bourdon tube inherently measures gauge pressure.

Bourdon tubes are usable up to about 50 MPa. Where an electrical output is required, the tube can be coupled to a potentiometer or Linear Variable Differential Transformer (LVDT).

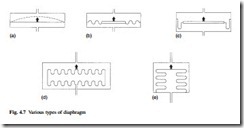

Diaphragms can also be used to convert a pressure differential into a mechanical displacement. Various arrangements are shown in Fig. 4.7. The displacement can be measured by LVDTs (section 4.5.3) or strain gauges (section 4.7.2).

Piezo elements

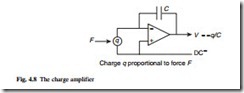

The piezoelectric effect occurs in quartz crystals. An electrical charge appears on the faces when a force is applied. The charge, q, is directly proportional to the applied force, which can be related to pressure with suitable diaphragms. The resulting charge is converted to a voltage by the circuit shown in Fig. 4.8 which is called a charge amplifier. The output voltage is given by:

As q is proportional to the force, V is proportional to the force applied to the crystal. In practice the charge leaks away, even with FET amplifiers and low leakage capacitors and piezoelectric transducers are thus unsuitable for measuring static pressures, but they have a fast response and are ideal for measuring fast dynamic pressure changes.

A related effect is the piezoresistive effect which results in a change in resistance with applied force. Piezoresistive devices are connected into a Wheatstone bridge.