Insulating materials

The reason for using insulating materials is to separate electrically the conducting parts of equipment from each other and from earthed components. Earthed components may include the mechanical casing or structure that is necessary to enable the equipment to be handled and to operate. Whereas the ‘active’ parts of the equipment play a useful role in its operation, the insulation is in many ways a necessary evil. For example in an electric motor the copper of the winding and the steel core making up the magnetic circuit are the active components and both contribute to the power output of the motor; the insulation which keeps these two components apart contributes nothing, in fact it takes up valuable space and it may be considered by the designer as not much more than a nuisance.

For these reasons, insulating materials have become a design focus in many types of electrical equipment, with many companies employing specialists in this field and carrying out sophisticated life testing of insulation systems. Such is the importance attached to this field that major international conferences on the subject are held reg- ularly, for instance by the IEEE in USA, IEE and Electrical Insulation Association (EIA) in UK and the European Electrical Insulation Association (EEIM) in Europe, all of which publish the papers presented. Conferences are also held in Canada, India and South Africa.

The simplest way to define an insulating material is to state what it is not. It is not a good conductor of electricity and it has a high electrical resistance that decreases with rising temperature, unlike conductors. The following are the most important properties of insulating materials:

● volume resistivity, which is also known as specific resistance

● relative permittivity (or dielectric constant), which is defined as the ratio of the electric flux density produced in the material to that produced in vacuum by the same electric field strength. The definitions have been set down in eqns 2.1 and

2.2. Relative permittivity can be expressed as the ratio of the capacitance of a capacitor made of that material to that of the same capacitor using vacuum as its dielectric (see eqn 2.11).

● dielectric loss (or electrical dissipation factor), which is defined as the ratio of the power loss in a dielectric material to the total power transmitted through it. It is given by the tangent of the loss angle and is commonly known as tan delta. Tan delta has been defined in eqn 2.43.

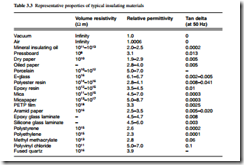

The volume resistivity, relative permittivity and tan delta values for a range of insulating materials are shown in Table 3.3.

The most important characteristic of an insulating material is its ability to with- stand electric stress without breaking down. This ability is sometimes known as its

dielectric strength, and is usually quoted in kilovolts per millimetre (kV/mm). Typical values may range from 5 to 100 kV/mm, but it is dependent on a number of other fac- tors which include the speed of application of the electric field, the length of time for which it is applied, temperature and whether ac or dc voltage is used.

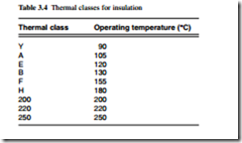

Another significant aspect of all insulating materials that dominates the way in which they are categorized is the maximum temperature at which they will perform satisfactorily. Generally speaking, insulating materials deteriorate over time more quickly at higher temperatures and the deterioration can reach a point at which the insulation ceases to perform its required function. This characteristic is known as ageing, and for each material it has been usual to assign a maximum temperature beyond which it is unwise to operate if a reasonable life is to be achieved. The main gradings or classes of insulation as defined in IEC 60085:1984 and its UK equivalent BS 2757:1986(1994) are listed in Table 3.4. Where a thermal class is used to describe

an item of electrical equipment, it normally represents the maximum temperature found within that product under rated load and other conditions. However, not all the insulation is necessarily located at the point of maximum temperature, and insulation with a lower thermal classification may be used in other parts of the equipment.

The ageing of insulation depends not only on the physical and chemical properties of the material and the thermal stress to which it is exposed, but also on the presence and degree of influence of mechanical, electrical and environmental stresses. The processing of the material during manufacture and the way in which it is used in the complete equipment may also significantly affect the ageing process. The definition of a useful lifetime will also vary according to the type and usage of equipment; for instance the running hours of a domestic appliance and a power station generator will be very different over a 25-year period. All of these factors should therefore influence the choice of insulating material for a particular application.

There is therefore a general movement in the development of standards and methods of testing for insulating materials towards the consideration of combinations of materials or insulating systems, rather than focusing on individual materials. It is not uncommon to consider life testing in which more than one form of stress is introduced; this is known as multifunctional or multifactor testing.

Primary insulation is often taken to mean the main insulation, as in the PVC coating on a live conductor or wire. Secondary insulation refers to a second ‘line of defence’ which ensures that even if the primary insulation is damaged, the exposed live component does not cause an outer metal casing to become live. Sleeving is frequently used as a secondary insulation.

Insulating materials may be divided into basic groups which are solid dielectrics, liquid dielectrics, gas and vacuum. Each is covered separately in the following sections.

Solid dielectrics

Solid dielectric insulating materials have in the past (for instance in BS 5691-2:1995 and IEC 60216-2:1990) been subdivided into three general groups as follows:

● solid insulation of all forms not undergoing a transformation during application

● solid sheet insulation for winding or stacking, obtained by bonding super- imposed layers

● insulation which is solid in its final state, but is applied in the form of a liquid or paste for filling, varnishing or bonding

A more convenient and up-to-date way to subdivide this very large group of materials is used by the IEC Technical Committee 15: Insulating Materials, and is as follows:

● inorganic (ceramic and glass) materials

● plastic films

● flexible insulating sleeving

● rigid fibrous reinforced laminates

● resins and varnishes

● pressure-sensitive adhesive tapes

● cellulosic materials

● combined flexible materials

● mica products

This subdivision is organized on the basis of application and is therefore more helpful to the practising engineer. A brief description of each of these classes of material is given in the following sections.

Inorganic (ceramic and glass) materials

A major application for materials in this category is in high-voltage overhead lines as suspension insulators (see Figs 13.2 and 13.8), or as bushings on high-voltage transformers and switchgear (see Fig. 6.14). In either case the material is formed into a series of flanged discs to increase the creepage distance along the surface of the complete insulator. Ceramic materials are used for a number of reasons, which include:

● ease of production of a wide range of shapes

● good electrical breakdown strength

● retention of insulating characteristics in the event of surface damage

Plastic films

Materials such as polyethylene terephthalate (PETP, more commonly referred to as polyester), polycarbonate, polyimide and polyethylene naphthalate (PEN) have been used as films, depending on the operating temperature requirement, in a variety of applications. These include the insulation between foils in capacitors, slot insulation in rotating electrical machines (either itself or as a composite with other sheet materials) and more recently as a backing for mica-based products used in the insulation of high- voltage equipment. Plastic films are used in applications requiring dimensional stability, high dielectric strength, moisture resistance and physical toughness.

Flexible insulating sleeving

This fulfils a number of requirements including the provision of primary or secondary electrical insulation of component wiring, the protection of cables and components from the deleterious effects of mechanical and thermal damage, and as a rapid and low-cost method of bunching and containing cables. Sleevings may find application in electrical machines, transformers, domestic and heating appliances, light fittings, cable connections, switchgear and as wiring harnesseses in domestic appliances and in vehicles. They are used because of their ease of application, flexibility and high dielec- tric strength and they lend themselves to an extremely wide range of formats. These include shrink sleeving, expandable constructions and textile-reinforced grades incorporating glass, polyester, aramid or keramid yarns, or sometimes a combination together with a coating of acrylic, silicone or polyurethane resins, for low and high voltage and temperatures across the range −70°C to + 450°C.

Rigid fibrous reinforced laminates

In the manufacture of most electrical equipment, there is a need for items machined out of solid board or in the form of tubes and rods. These items can take the form of densified wood or laminates of paper, woven cotton, glass or polyester, or glass or polyester random mats laminated together with a thermosetting resin which might be phenolic, epoxy, polyester, melamine, silicone or polyimide, depending upon the properties required. Rigid boards are used because they are capable of being machined to

size, and they retain their shape and properties during their service life, unlike unseasoned timber which was used in early equipment.

Resins and varnishes

In addition to their use in the laminates outlined in section 3.3.1.4, a wide range of varnishes and resins are used by themselves in the impregnation and coating of electrical equipment in order to improve its resistance to working conditions, to enhance its electrical characteristics and to increase its working life. At first many resins and varnishes were based on naturally occurring materials such as bitumen, shellac and vegetable oils, but now they are synthetically produced in a comprehensive range of thermo- plastic, thermosetting and elastomeric forms. The more common types are phenolic, polyester, epoxy, silicone and polyimide, and these can be formulated to provide the most suitable processing and the required final characteristics. Varnishes and resins are used because of their ability to impregnate, coat and bond basic insulating materials; this assists in the application of the insulating materials and it significantly improves their service life and their ability to withstand dirt and moisture.

Pressure-sensitive adhesive tapes

Certain types of pressure-sensitive adhesive (PSA) tapes have become so much a part of modern life that the trade names have been absorbed into everyday language. The usefulness of PSA in short lengths for holding down, sealing or locating applies equally in the field of insulation and a range of tapes has been developed which is based on paper, films (as in section 3.3.1.2) or woven glass cloth, coated with suitable adhesive such as rubber, silicone or acrylic.

Cellulosic materials

Materials in the form of papers, pressboards and presspapers continue to play a vital role in oil-filled power transformers. Included in this area are also other materials which are produced by paper-making techniques, but which use aramid fibres; these materials find wide application in high-temperature and dry-type transformers as well as in other types of electrical equipment. Cellulose materials are mainly used in con- junction with oil, and it is their porous nature which lends itself to successful use in transformers and cables.

Combined flexible materials

In order to produce suitable materials with the required properties such as tear strength, electric strength and thermal resistance at an acceptable price, a range of laminated or combined flexible sheet products has been developed. These employ cellulosic, poly- ester and aramid papers or fleeces, also glass and polyester fabrics as well as other mate- rials, in combination with many of the plastic films already referred to, in a range of forms to suit the application. These products are used in large quantities in low-voltage electric motors and generators.

Mica products

Materials based on mica, a naturally occurring mineral, play a central part in the design and manufacture of high-voltage rotating machines. Originally the material was

in the form of mica splittings, but at present the industry uses predominantly micapaper, which is produced by breaking down the mica into small platelets by chemical or mechanical means, producing a slurry and then feeding this through a traditional paper- making machine. The resulting micapaper, when suitably supported by a woven glass or film backing (see section 3.3.1.2) and impregnated with epoxy or a similar resin, is used to insulate the copper bars which make up the stator winding of the machine. Micapaper is used in the ground insulation of the winding which is shown as part of the stator slot section illustrated in Fig. 3.5.

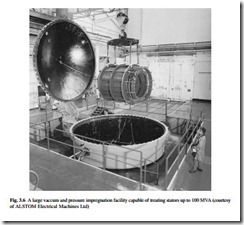

Micapaper products are available in a resin-rich form, in which all the necessary resin for consolidation of the insulation around the winding is included within the material. This consolidation is usually carried out in large steam or electrically heated presses into which an insulated coil side or bar can be placed; heat and pressure are then applied as necessary to cure fully the resin-rich micapaper insulation. Alternatively, micapaper products are available for use with Vacuum Pressure Impregnation (VPI), in which most of the resin is introduced after winding the machine. The use of VPI eliminates the need to consolidate the insulation in a press; consolidation is achieved either by the use of hydrostatic forces or by ensuring full impregnation of the bars or coils already placed or wound into slots. A large electrical machine stator is shown being lowered into a VPI tank in Fig. 3.6.

Mica-based products dominate high-voltage insulation systems because of their unique combination of properties, which include the following:

● high dielectric strength

● low dielectric loss at high frequency

● high surface and volume resistivity

● excellent resistance to corona discharge and electric arc erosion

● temperature capability from −273°C to 1000°C

● flame resistance

● excellent chemical resistance

● high resistance to compressive forces

Textile insulation

Although the use of fully varnished fabric is becoming less common, products using glass and polyester-based yarn, and to a lesser extent cotton and rayon, are still in use.

A much larger range of unvarnished narrow-fabric products, more commonly called woven tapes, exists and these products use various combinations of glass, polyester and aramid yarns to meet specific applications. Primarily these tapes are used as finishing on top of other insulation such as micapaper, in order to provide a tough outer surface which can readily be coated with a final varnish or paint finish. When manufactured on modern needle looms they are an economic proposition.

Woven tapes are used because of their ease of application, good conformity and bed- ding down. An example of the complex shapes that they can be used to cover is shown in Fig. 3.7, which illustrates the endwinding of a high-voltage electrical machine.

Elastomers and thermoplastics

There is a very wide range of polymeric and rubber-like insulation materials. These have traditionally been dealt with in connection with electric cables and IEC and BSI reflect this by dealing with them separately in Technical Committee 20: Electrical Cables.

Some elastomers such as silicone have found application in sleeving, traction systems and increasingly as overhead line insulators, but the bulk of their application continues to be related to cables. The leading materials such as PVC, MDPE, XLPE and EPR are therefore referred to in Chapter 9.

Liquid dielectrics

A liquid dielectric remains in the liquid state throughout its working life, unlike resins and varnishes which become solid after processing.

The principal uses of liquid dielectrics are as a filling and cooling medium for trans- formers, capacitors and rheostats, as an arc-quenching medium in switchgear and as an impregnant of absorbent insulation used mainly in transformers, switchgear, capacitors and cables. The important properties of dielectric liquids are therefore electric strength, viscosity, chemical stability and flashpoint.

Typical materials include highly refined hydrocarbon mineral oils obtained from selected crude petroleum, silicone fluids, synthetic esters and hydrocarbons with high molecular weight. A specially interesting material for cables has been the waxy Mineral Insulating Non-Draining (MIND) compound which has been used in paper- insulated cables; this is described in section 9.2.3. A group of polychlorinated biphenyls (PCBs) has been used in transformers, but these materials are now being

replaced and carefully disposed of because of their toxic nature and their resistance to biological and chemical degradation.

Gas insulation

Two gases already in common use for insulation are nitrogen and sulphur hexafluoride (SF6). Nitrogen is used as an insulating medium in some sealed transformers, while SF6 is finding increasing use in transmission and distribution switchgear because of its insulating properties and its arc-extinguishing capabilities; this is described further in sections 7.4.1 and 7.5.3.2.![]()

Vacuum insulation

Vacuum insulation is now used in a range of medium-voltage switchgear. Like SF6, it has both insulating and arc-extinguishing properties. The action of vacuum in a circuit breaker is explained in section 7.4.1.

Standards

A selection of national and international standards covering the insulation field is given in Table 3.5. The majority of the IEC standards with their EN and BSEN equiv- alents consist of three parts as follows:

● Part 1: Definitions, classsification and general requirements

● Part 2: Methods of test

● Part 3: Specifications for individual materials