Hazardous area equipment

Methods of protection

Electrical equipment has been used in potentially explosive atmospheres for over one hundred years and several methods of protection have been developed during that time. The probability of the equipment becoming an effective source of ignition determines the zone of use. Equipment with a higher probability of being an effective source of ignition can be used only in the zones of lower hazard. The 94/9/EC Directive and the EPS regulations recognize this in specifying the corresponding category for the equipment. All the methods of protection use one or more of only four basic techniques which are summarized in Table 15.3.

Type of Protection n is another method of protection for electrical equipment which uses simplified versions of the methods above and is category 3 only (see Table 15.4). All the above methods of protection were originally developed for use with flammable gases and vapours. There is a further method of protection specifically for combustible dust and several of the methods of protection for gases and vapours have been adapted for use with combustible dust (see Table 15.5).

All the above methods of protection have standards for their design and construction which address most of the EHSRs of the ATEX directive, and hence the EPS regulations; the remaining EHSRs are concerned with instructions for use and other essential information for the end-user.

It is also possible to design and construct equipment which complies with the EHSRs with no reference, or only partial reference, to supporting standards. This equip- ment will carry only the marking specified in the directive without the identifying letters above.

Temperature classes and apparatus groups

Equipment for use in potentially explosive atmospheres must also be suitable for the ignition characteristics of the flammable material. IEC 79-20:1996 (reference 15P)

lists the properties of approximately 400 flammable gases and vapours. The relevant properties are:

● Auto-ignition temperature (AIT) – the temperature at which the most easily ignited mixture with air will ignite

● Minimum ignition energy/minimum ignition current (MIE/MIC) – the smallest amount of energy or current in a spark which will ignite the most easily ignited mixture with air

● Maximum experimental safe gap (MESG) – the largest gap between parts of a flameproof enclosure through which the internal explosion will not propagate to ignite a surrounding flammable atmosphere

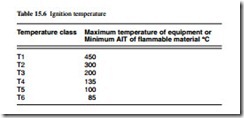

The AIT is used to select equipment on the basis of the temperature of the equipment. The temperature of the equipment must not be greater than the AIT of the surrounding atmosphere. The equipment for use in a potentially explosive atmosphere will be marked with a temperature class (T class), a maximum temperature or both.

In Table 15.6, the maximum temperature of equipment is the temperature of the hottest part of the equipment to which the flammable atmosphere has unprotected access, for instance the external temperature of flameproof equipment but the internal temperature of increased safety equipment.

The ambient temperature in which the equipment is used affects the temperature of the equipment, so a maximum ambient temperature is also specified. The normal maximum ambient temperature is 40°C unless an alternative is marked on the equip- ment. Minimum ambient temperature is also specified; this is −20°C unless marked otherwise.

The MIE and MESG of flammable gases and vapours have been measured and fall into three distinct bands. This has been used to produce three sets of design criteria in the standards for non-mining equipment and a separate set for mining equipment.

These allow equipment to be designated as Group I for underground mining applications and Group II elsewhere. Within Group II, apparatus is designated as IIA, IIB or IIC according to the design criteria used, the IIC design criteria being the most stringent and that of IIA being the least stringent (see Table 15.8). The subgroups A, B and C are important only if the method of protection relies on limitation of energy or current, for instance Intrinsic Safety or Type of Protection nL, or on containment of an explosion such as a flameproof enclosure. Otherwise the equipment is allocated to the whole of Group II.

For convenience IEC 79-20 lists the Group and Temperature Class of equipment suitable for each flammable material.