Brake Test

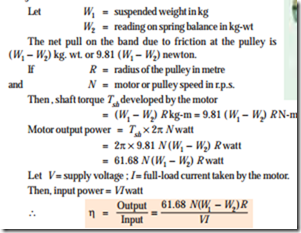

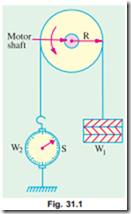

It is a direct method and consists of applying a brake to a water-cooled pulley mounted on the motor shaft as shown in Fig. 31.1. The brake band is fixed with the help of wooden blocks gripping the pulley. One end of the band is fixed to earth via a spring balance S and the other is connected to a suspended weight W1. The motor is running and the load on the motor is adjusted till it carries its full load current.

The simple brake test described above can be used for small motors only, because in the case of large motors, it is difficult to dissipate the large amount of heat generated at the brake.

Another simple method of measuring motor output is by the use of poney brake one form of which is shown in Fig. 31.2 (a). A rope is wound round the pulley and its two ends are attached to two spring balances S1 and S2. The tension of the rope can be adjusted with the help of swivels. Obviously, the force acting tangentially on the pulley is equal to the difference between the readings of the two spring balances. If R is the pulley radius, the torque at the pulley is Tsh = (S1 – S2)R. If w (= 2pN) is the angular velocity of the pulley, then motor output = sh ´ w = 2 p N (S1 – S2)R m-kg. wt. = 9.81 ´ 2pN (S1 – S2) R watt.

The motor input may be measured as shown in Fig. 31.2 (b). Efficiency may, as usual, be found by using the relation h = output/input.

Example 31.1. In a brake test the effective load on the branch pulley was 38.1 kg, the effective diameter of the pulley 63.5 cm and speed 12 r.p.s. The motor took 49 A at 220 V. Calculate the output power and the efficiency at this load.

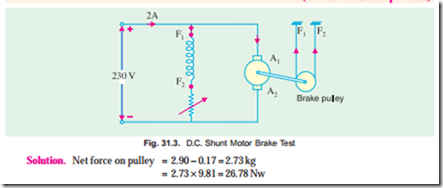

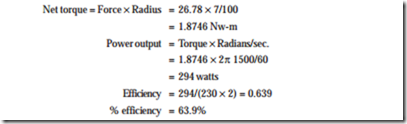

Example 31.2(b). In a brake-test, on a d.c. shunt motor, the tensions on the two sides of the brake were 2.9 kg and 0.17 kg. Radius of the pulley was 7 cm. Input current was 2 amp at 230 volts. The motor speed was 1500 rpm. Find the torque, power-output and efficiency.

(Bharathiar Univ. April 1998)

Swinburne’s* Test (or No-load Test or Losses Method)

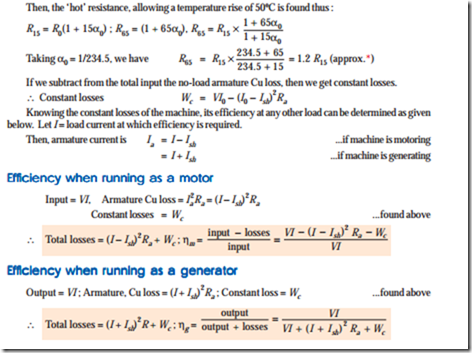

It is a simple method in which losses are measured separately and from their knowledge, efficiency at any desired load can be predetermined in advance. The only running test needed is no-load test. However, this test is applicable to those machines in which flux is practically constant shunt and compound-wound machines.

The machine is running as a motor on no-load at its rated voltage i.e. voltage stamped on the name- plate. The speed is adjusted to the rated speed with the help of shunt regulator as shown in Fig. 31.4.

The no-load current I0 is measured by the ammeter A1 whereas shunt field current Ish is given by ammeter A2. The no-load armature current is (I0 – Ish) or Ia0.

Related posts:

Incoming search terms:

- brake test on dc series motor theory

- break test on dc series motor

- brake test on dc machine

- brake test on dc shunt motor

- brake test On DC shunt motor theory

- brake test on dc compound motor

- brake test of dc machine

- brake load test on a dc series motor

- brake test on dc motor

- break test on dc shunt motor

- brake test on DC compound motor theory

- why brake test is performed only on small machine

- break test of dc series motor

- Brake test of dc motor

- motor braking test

- briefly explain brake test performed on dc series motor

- describe brake test on dc series motor

- break test on dc compound motor theory

- break test on dc shunt motor theory

- Brake test in dc machine

- Break load test on DC motor

- brake load test

- brake test in dc motor

- breake test in dc motor

- brake test on dc series

- brake test of motor

- explain brake test performed on dc series motor

- why should we conduct dc machine tests

- break test in DC motor

- brake test

- break test on dc motor

- brake test on a dc compound motor theory

- Dc machines what is the difference between rope test and indirect test

- brake test of dc machines

- dc motor brake test

- expression for input and output powe for break test on dc shunt motor

- Brake test dc machine

- break test

- what need dc motor break test

- what is the use of brake test of im

- difference between brake test and swineburns test

- brake test for dc machine

- advantages of Brake Test of DC Motor

- brake test on dc machines

- break test on dc shunt motor experiment theory

- perform brake test on dc series motor

- break load test on dc shunt motor

- perform brake test on dc series motor practical

- break test of dc motor

- direct testing of dc machine