Interfacing Analog to Digital Data Converters

• In most of the cases, the PIO 8255 is used for interfacing the analog to digital converters with microprocessor.

• We have already studied 8255 interfacing with 8086 as an I/O port, in previous section. This section we will only emphasize the interfacing techniques of analog to digital converters with 8255.

• The analog to digital converters is treaded as an input device by the microprocessor, that sends an initialising signal to the ADC to start the analogy to digital data conversation process. The start of conversation signal is a pulse of a specific duration.

• The process of analog to digital conversion is a slow process, and the microprocessor has to wait for the digital data till the conversion is over. After the conversion is over, the ADC sends end of conversion EOC signal to inform the microprocessor that the conversion is over and the result is ready at the output buffer of the ADC. These tasks of issuing an SOC pulse to ADC, reading EOC signal from the ADC and reading the digital output of the ADC are carried out by the CPU using 8255 I/O ports.

• The time taken by the ADC from the active edge of SOC pulse till the active edge of EOC signal is called as the conversion delay of the ADC.

• It may range any where from a few microseconds in case of fast ADC to even a few hundred milliseconds in case of slow ADCs.

• The available ADC in the market use different conversion techniques for conversion of analog signal to digitals. Successive approximation techniques and dual slope integration techniques are the most popular techniques used in the integrated ADC chip.

• General algorithm for ADC interfacing contains the following steps:

1. Ensure the stability of analog input, applied to the ADC.

2. Issue start of conversion pulse to ADC

3. Read end of conversion signal to mark the end of conversion processes.

4. Read digital data output of the ADC as equivalent digital output.

5. Analog input voltage must be constant at the input of the ADC right from the start of conversion till the end of the conversion to get correct results. This may be ensured by a sample and hold circuit which samples the analog signal and holds it constant for a specific time duration. The microprocessor may issue a hold signal to the sample and hold circuit.

6. If the applied input changes before the complete conversion process is over, the digital equivalent of the analog input calculated by the ADC may not be correct.

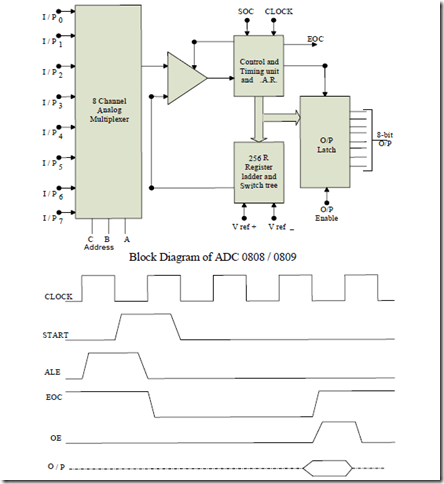

ADC 0808/0809 :

• The analog to digital converter chips 0808 and 0809 are 8-bit CMOS, successive approximation converters. This technique is one of the fast techniques for analog to digital conversion. The conversion delay is 100µs at a clock frequency of 640 KHz, which is quite low as compared to other converters. These converters do not need any external zero or full scale adjustments as they are already taken care of by internal circuits. These converters internally have a 3:8 analog multiplexer so that at a time eight different analog conversion by using address lines – ADD A, ADD B, ADD C. Using these address inputs, multichannel data acquisition system can be designed using a single ADC. The CPU may drive these lines using output port lines in case of multichannel applications. In case of single input applications, these may be hardwired to select the proper input.

• There are unipolar analog to digital converters, i.e. they are able to convert only positive analog input voltage to their digital equivalent. These chips do no contain any internal sample and hold circuit.

Timing Diagram of ADC 0808

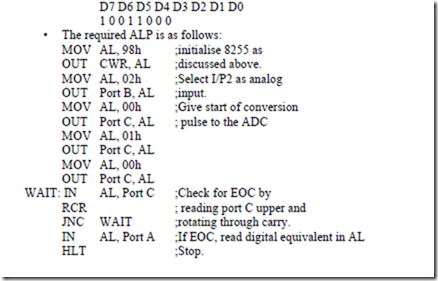

• Example: Interfacing ADC 0808 with 8086 using 8255 ports. Use port A of 8255 for transferring digital data output of ADC to the CPU and port C for control signals. Assume that an analog input is present at I/P2 of the ADC and a clock input of suitable frequency is available for ADC.

• Solution: The analog input I/P2 is used and therefore address pins A,B,C should be 0,1,0 respectively to select I/P2. The OE and ALE pins are already kept at +5V to select the ADC and enable the outputs. Port C upper acts as the input port to receive the EOC signal while port C lower acts as the output port to send SOC to the ADC.

• Port A acts as a 8-bit input data port to receive the digital data output from the ADC. The 8255 control word is written as follows:

Interfacing 0808 with 8086

Interfacing Digital To Analog Converters

INTERFACING DIGITAL TO ANALOG CONVERTERS: The digital to analog converters convert binary number into their equivalent voltages. The DAC find applications in areas like digitally controlled gains, motors speed controls, programmable gain amplifiers etc.

AD 7523 8-bit Multiplying DAC : This is a 16 pin DIP, multiplying digital to analog converter, containing R-2R ladder for D-A conversion along with single pole double thrown NMOS switches to connect the digital inputs to the ladder.

The pin diagram of AD7523 is shown in fig the supply range is from +5V to+15V, while Vref may be any where between -10V to +10V. The maximum analog output voltage will be any where between -10V to +10V, when all the digital inputs are at logic high state.

Usually a zener is connected between OUT1 and OUT2 to save the DAC from negative transients. An operational amplifier is used as a current to voltage converter at the output of AD to convert the current out put of AD to a proportional output voltage.

It also offers additional drive capability to the DAC output. An external feedback resistor acts to control the gain. One may not connect any external feedback resistor, if no gain control is required.

EXAMPLE: Interfacing DAC AD7523 with an 8086 CPU running at 8MHZ and write an assembly language program to generate a sawtooth waveform of period 1ms with Vmax 5V.

Solution: Fig shows the interfacing circuit of AD 74523 with 8086 using 8255. program gives an ALP to generate a sawtooth waveform using circuit.

• In the above program, port A is initialized as the output port for sending the digital data as input to DAC. The ramp starts from the 0V (analog), hence AL starts with 00H. To increment the ramp, the content of AL is increased during each execution of loop till it reaches F2H.

• After that the saw tooth wave again starts from 00H, i.e. 0V(analog) and the procedure is repeated. The ramp period given by this program is precisely 1.000625 ms. Here the count F2H has been calculated by dividing the required delay of 1ms by the time required for the execution of the loop once. The ramp slope can be controlled by calling a controllable delay after the OUT instruction.