Open Feed water Heater

A reheat steam cycle with a single open feedwater heater is depicted in Fig. 12.4 together with the corresponding T-s-diagram. In the open feedwater heater, compressed liquid water coming from the low pressure pump (P1, state 2) is mixed isobarically with some of the steam leaving the high pressure turbine (T1, state 6). The mixing ratio is adjusted such that the resulting mixture (state 3) is saturated liquid at the mixing pressure p3 = p2 = p6. The high pressure pump (P2) compresses this liquid to p4 before it is fed into the boiler where it is heated, evaporated and superheated to state 5.

The high-pressure, high-temperature steam is expanded in the high pressure turbine and then split into the stream to the feedwater heater, and the main stream. The latter is reheated in the boiler (6-7), expanded in the low pressure turbine (7-8), condensed (8-1), and compressed (1-2), before it enters the feedwater heater.

As the figure indicates, the working fluid undergoes two different cycles. The main stream m˙ A undergoes the full cycle 1-2-3-4-5-6-7-8-1 (continuous line), while the mass flow m˙ B bled-off after the high pressure turbine under- goes the cycle 3-4-5-6-3 (dashed line).

The heat added to this process from the fuel is

and takes place at relatively high temperature. The low temperature heating 2-3 occurs through internal heat exchange in the open feedwater heater.

Increase of the average temperature for external heat addition increases the thermal efficiency, and this is why the open feedwater heater gives better efficiency.

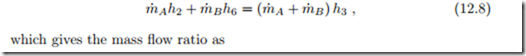

The mass flow ratio is determined from the energy balance for the feedwater heater. We assume that the feedwater heater has no heat loss to the environment, so that