Thermal expansion

Thermal expansion and contraction are very important features in engineering science. For example, if the metal railway lines of a railway track are heated or cooled due to weather conditions or time of day, their lengths can increase or decrease accordingly. If the metal lines are heated due to the weather effects, then the railway lines will attempt to expand, and depending on their construction, they can buckle, rendering the track useless for transporting trains. In countries with large temperature variations, this effect can be much worse, and the engineer may have to choose a superior metal to withstand these changes. The effect of metals expanding and contracting due to the rise and fall of temperatures, accordingly, can also be put to good use. A classic example of this is the simple humble domestic thermostat, which when the water gets too hot, will cause the metal thermostat to expand and switch off the electric heater; conversely, when the water becomes too cool, the metal thermostat shrinks, causing the electric heater to switch on again. All sorts of materials, besides metals, are affected by thermal expansion and contraction. The chapter also defines the coefficients of linear, superficial and cubic expansion.

At the end of this chapter you should be able to:

• appreciate that expansion and contraction occurs with change of temperature

• describe practical applications where expansion and contraction must be allowed for

• understand the expansion and contraction of water

• define the coefficient of linear expansion α

• recognise typical values for the coefficient of linear expansion

• calculate the new length L , after expansion or

• define the coefficient of superficial expansion β

• calculate the new surface area A2, after expansion or contraction, using A2 = A1 [1 + β(t2 – t1)]

• appreciate that β ≈ 2α

• define the coefficient of cubic expansion γ

• recognise typical values for the coefficient of cubic expansion

• appreciate that γ ≈ 3α

• calculate the new volume V2, after expansion or contraction, using V2 = V1 [1 + γ(t2 – t1)]

Introduction

When heat is applied to most materials, expansion occurs in all directions (see Section 2.12, page 33). Conversely, if heat energy is removed from a material (i.e. the material is cooled) contraction occurs in all directions. The effects of expansion and contraction each depend on the change of temperature of the material.

Practical applications of thermal expansion

Some practical applications where expansion and con- traction of solid materials must be allowed for include:

(i) Overhead electrical transmission lines are hung so that they are slack in summer, otherwise their contraction in winter may snap the conductors or bring down pylons.

(ii) Gaps need to be left in lengths of railway lines to prevent buckling in hot weather (except where these are continuously welded).

(iii) Ends of large bridges are often supported on rollers to allow them to expand and contract freely.

(iv) Fitting a metal collar to a shaft or a steel tyre to a wheel is often achieved by first heating the collar or tyre so that they expand, fitting them in position, and then cooling them so that the contraction holds them firmly in place; this is known as a ‘shrink-fit’. By a similar method hot rivets are used for joining metal sheets.

(v) The amount of expansion varies with different materials. Figure 21.1(a) shows a bimetallic strip at room temperature (i.e. two different strips of metal riveted together – see Section 2.12, page 33). When heated, brass expands more than steel, and since the two metals are riveted together the bimetallic strip is forced into an arc as shown in Figure 21.1(b). Such a movement can be arranged to make or break an electric circuit and bimetallic strips are used, in particular, in thermostats (which are temperature- operated switches) used to control central heating systems, cookers, refrigerators, toasters, irons, hot-water and alarm systems.

(vi) Motor engines use the rapid expansion of heated gases to force a piston to move.

(vii) Designers must predict, and allow for, the expansion of steel pipes in a steam-raising plant so as to avoid damage and consequent danger to health.

Expansion and contraction of water

Water is a liquid that at low temperature displays an unusual effect. If cooled, contraction occurs until, at about 4°C, the volume is at a minimum. As the temperature is further decreased from 4°C to 0°C expansion occurs, i.e. the volume increases. (For cold, deep fresh water, the temperature at the bottom is more likely to be about 4°C, somewhat warmer than less deep water). When ice is formed, considerable expansion occurs and it is this expansion that often causes frozen water pipes to burst.

A practical application of the expansion of a liquid is with thermometers, where the expansion of a liquid, such as mercury or alcohol, is used to measure temperature.

Coefficient of linear expansion

The amount by which unit length of a material expands when the temperature is raised one degree is called the coefficient of linear expansion of the material and is represented by α (Greek alpha) – see Section 2.12, page 33.

The units of the coefficient of linear expansion are m/(mK), although it is usually quoted as just/K or K–1. For example, copper has a coefficient of linear expansion value of 17 × 10–6 K–1, which means that a 1 m long bar of copper expands by 0.000017 m if its temperature is increased by 1 K (or 1°C). If a 6 m long bar of copper is subjected to a temperature rise of 25 K then the bar will expand by (6 × 0.000017 × 25) m, i.e. 0.00255 m or 2.55 mm. (Since the Kelvin scale uses the same temperature interval as the Celsius scale, a change of temperature of, say, 50°C, is the same as a change of temperature of 50 K).

If a material, initially of length L1 and at a tempera- ture of t1 and having a coefficient of linear expansion α, has its temperature increased to t2, then the new length L2 of the material is given by:

New length = original length + expansion

Problem 1. The length of an iron steam pipe is 20.0 m at a temperature of 18°C. Determine the length of the pipe under working conditions when the temperature is 300°C. Assume the coefficient of linear expansion of iron is 12 × 10–6 K–1.

In practice, allowances are made for such expansions.

U-shaped expansion joints are connected into pipelines carrying hot fluids to allow some ‘give’ to take up the expansion.

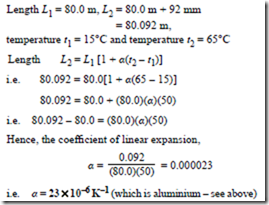

Problem 2. An electrical overhead transmission line has a length of 80.0 m between its supports at 15°C. Its length increases by 92 mm at 65°C.

Determine the coefficient of linear expansion of the material of the line.

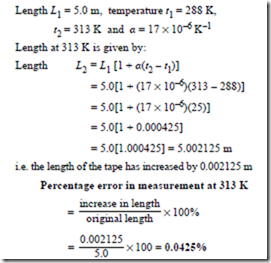

Problem 3. A measuring tape made of copper measures 5.0 m at a temperature of 288 K.

Calculate the percentage error in measurement when the temperature has increased to 313 K. Take the coefficient of linear expansion of copper as 17 × 10–6 K–1.

Problem 4. The copper tubes in a boiler are 4.20 m long at a temperature of 20°C. Determine the length of the tubes (a) when surrounded only by feed water at 10°C (b) when the boiler is operating and the mean temperature of the tubes is 320°C. Assume the coefficient of linear expansion of copper to be 17 × 10–6 K–1.

i.e. the tube extends by 21.4 mm when the temperature rises from 20°C to 320°C

Now try the following Practise Exercise

Practise Exercise 112 Further problems on the coefficient of linear expansion

1. A length of lead piping is 50.0 m long at a temperature of 16°C. When hot water flows through it the temperature of the pipe rises to 80°C. Determine the length of the hot pipe if the coefficient of linear expansion of lead is 29 × 10–6 K–1. [50.0928 m]

2. A rod of metal is measured at 285 K and is 3.521 m long. At 373 K the rod is 3.523 m long. Determine the value of the coefficient of linear expansion for the metal.

[6.45 × 10–6 K–1]

3. A copper overhead transmission line has a length of 40.0 m between its supports at 20°C. Determine the increase in length at 50°C if the coefficient of linear expansion of copper is 17 × 10–6 K–1. [20.4 mm]

4. A brass measuring tape measures 2.10 m at a temperature of 15°C. Determine

(a) the increase in length when the tempera- ture has increased to 40°C

(b) the percentage error in measurement at 40°C. Assume the coefficient of linear expansion of brass to be 18 × 10–6 K–1.

[(a) 0.945 mm (b) 0.045%]

5. A pendulum of a ‘grandfather’ clock is 2.0 m long and made of steel. Determine the change in length of the pendulum if the temperature rises by 15 K. Assume the coefficient of linear expansion of steel to be 15 × 10–6 K–1. [0.45 mm]

6. A temperature control system is operated by the expansion of a zinc rod which is 200 mm long at 15°C. If the system is set so that the source of heat supply is cut off when the rod has expanded by 0.20 mm, determine the temperature to which the system is limited. Assume the coefficient of linear expansion of zinc to be 31 × 10–6 K–1. [47.26°C]

7. A length of steel railway line is 30.0 m long when the temperature is 288 K. Deter- mine the increase in length of the line when the temperature is raised to 303 K. Assume the coefficient of linear expansion of steel to be 15 × 10–6 K–1. [6.75 mm]

8. A brass shaft is 15.02 mm in diameter and has to be inserted in a hole of diameter 15.0 mm. Determine by how much the shaft must be cooled to make this possible, with- out using force. Take the coefficient of linear expansion of brass as 18 × 10–6 K–1. [74 K]

Related posts:

Incoming search terms:

- A brass road is 2m log at a ceetain temperature What its length for a temperature rise at look if the expansivity of brass is 18*10-6k-1?

- what is the linear expansivity of zinc

- to allow rail to move expand and contract freely

- Steel brass inch of length 3m at 29 decree census are to be used for constructing a railine If the linear expansivity of steel 1by10 rise to power minus 5 per kelvin calculate if the safety gaps that must be left If the highest temperature is 41 decree ce

- if the linear expansivity of a copper rod is 0 000017/k calculate the expansion of 10m of copper and rod when heated from 10c to 30 degree

- calculations of the coefficientof feed

- an iron rod 200 mm and al rod of 300 mm are at 0degree at what temperature their lenght will be same

- A steel rod m long of coefficient of linear expansivity temperature rise

- a nickel-steel rod at 21 degrees celsius is 0 62406 m in length raising the temperature at 31 degrees celsius produces an elongation of 121 6 m determine the length at 0 degrees celsius and the coefficient of linear expansion

- a length of a lead piping is 50 m long atba temperature of 16

- a brass rod has length of 80 0m when the temperature is zero degree celtious what is its length on a hot day when the temperature is 20 degree celtious

- A brass rod has a length of 50 0m when the temperature is 0°C what is its length on a hot day when the temperature is 20°C

- a brass rod has a length of 50 0m when the temperature is 0 degree Celsius what is its length on a hot day when the temperature is 20 degree Celsius

- Why does brass expand more than steel rod when subjected to heat