Electronic Speed Control Method for DC Motors

Of late, solid-state circuits using semiconductor diodes and thyristors have become very popular for controlling the speed of a.c. and d.c. motors and are progressively replacing the traditional electric power control circuits based on thyratrons, ignitrons, mercury arc rectifiers, magnetic amplifiers and motor-generator sets etc. As compared to the electric and electromechanical systems of speed control, the electronic methods have higher accuracy, greater reliability, quick response and also higher efficiency as there are no I 2R losses and moving parts. Moreover, full 4-quadrant speed control is possible to meet precise high-speed standards.

All electronic circuits control the motor speed by adjusting either (i) the voltage applied to the motor armature or (ii) the field current or (iii) both.

DC motors can be run from d.c. supply if available or from a.c. supply after it has been converted into d.c. supply with the help of rectifiers which can be either half-wave or full-wave and either controlled (by varying the conduction angle of the thyristors used) or uncontrolled.

AC motors can be run on the a.c. supply or from d.c. supply after it has been converted into a.c. supply with the help of inverters (opposite of rectifiers).

As stated above, the average output voltage of a thyristor-controlled rectifier can be changed by changing its conduction angle and hence the armature voltage of the d.c. motor can be adjusted to control its speed.

When run on a d.c. supply, the armature d.c. voltage can be changed with the help of a thyristor chopper circuit which can be made to interrupt d.c. supply at different rates to give different average values of the d.c. voltage. If d.c. supply is not available, it can be obtained from the available a.c. supply with the help of uncontrolled rectifiers (using only diodes and not thyristors). The d.c. voltages so obtained can be then chopped with the help of a thyristor chopper circuit.

A brief description of rectifiers, inverters* and d.c. choppers would now be given before discuss- ing the motor speed control circuits.

Uncontrolled Rectifiers

As stated earlier, rectifiers are used for a.c. to d.c. conversion i.e., when the supply is alternating but the motor to be controlled is a d.c. machine.

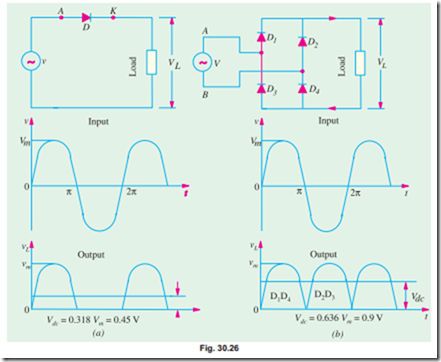

Fig. 30.26 (a) shows a half-wave uncontrolled rectifier. The diode D conducts only during positive half-cycles of the single-phase a.c. input i.e., when its anode A is positive with respect to its cathode K. As shown, the average voltage available across the load (or motor) is 0.45 V where V is the r.m.s. value of the a.c. voltage (in fact, V = Vm / 2 ). As seen it is a pulsating d.c. voltage.

In Fig. 30.26 (b) a single-phase, full-wave bridge rectifier which uses four semiconductor diodes and provides double the voltage i.e., 0.9 V is shown. During positive input half-cycles when end A is positive with respect to end B, diodes D1 and D4 conduct (i.e. opposite diodes) whereas during negative input half-cycles, D2 and D3 conduct. Hence, current flows through the load during both half- cycles in the same direction. As seen, the d.c. voltage supplied by a bridge rectifier is much less pulsating than the one supplied by the half-wave rectifier.

Controlled Rectifiers

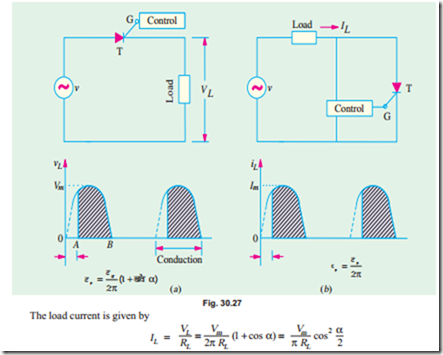

In these rectifiers, output load current (or voltage) can be varied by controlling the point in the input a.c. cycle at which the thyristor is turned ON with the application of a suitable low-power gate pulse. Once triggered (or fired) into conduction, the thyristor remains in the conducting state for the rest of the half-cycle i.e., upto 180º. The firing angle a can be adjusted with the help of a control circuit. When conducting, it offers no resistance i.e., it acts like a short-circuit.

Fig. 30.27 (a) shows an elementary half-wave rectifier in which thyristor triggering is delayed by angle a with the help of a phase-control circuit. As shown, the thyristor starts conducting at point A and not at point O because its gate pulse is applied after a delay of a. Obviously, the conduction angle is reduced from 180º to (180º – a) with a consequent decrease in output voltage whose value is given by

Fig. 30.28 (a) shows a single-phase, full-wave half-controlled rectifier. It is called half-con- trolled because it uses two thyristors and two diodes instead of four thyristors. During positive input half-cycle when A is positive, conduction takes place via T1, load and D1. During the negative half- cycle when B becomes positive, conduction route is via T2, load and D2.

As seen from the figure, when A is positive, D1 and D3 conduct provided T has been fired. In the negative half-cycle, D2 and D4 conduct via the load.

Thyristor Choppers

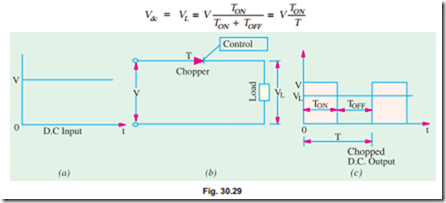

Since thyristors can be switched ON and OFF very rapidly, they are used to interrupt a d.c. supply at a regular frequency in order to produce a lower (mean) d.c. voltage supply. In simple words, they can produce low-level d.c. voltage from a high-voltage d.c. supply as shown in Fig. 30.29.

The mean value of the output voltage is given by

Fig. 30.30 (a) shows a simple thyristor chopper circuit alongwith extra commutating circuitry for switching T1 OFF. As seen, T1 is used for d.c. chopping, whereas R, T2 and C are used for commuta- tion purposes as explained below.

When T1 is fired into conduction by its control circuit (not shown), current is set up through the load and commutation capacitor C gets charged via R with the polarity shown in the figure during this ON period.

For switching T1 OFF, second thyristor T2 is triggered into conduction allowing C to discharge through it (since it acts as a short-circuit while conducting) which reverse-biases T1 thus turning it OFF. The discharge from C leaves T2 with reverse polarity so that it is turned OFF, whereas T1 is triggered into conduction again.

Depending upon the frequency of switching ON and OFF, the input d.c. voltage is cut into d.c. pulses as shown in Fig. 30.30 (c).

In Fig. 30.30 (b), T1 is the chopping thyristor, whereas C, D, T2 and L constitute the commutation circuitry for switching T1 OFF and ON at regular intervals.

When T2 is fired, C becomes charged via the load with the polarity as shown. Next, when T1 is fired, C reverse-biases T2 to OFF by discharging via T1, L and D and then recharges with reverse polarity. T2 is again fired and the charge on C reverse-biases T1 to non-conducting state.

It is seen that output (or load) voltage is present only when T1 is ON and is absent during the interval it is OFF. The mean value of output d.c. voltage depends on the relative values of TON and TOFF. In fact, output d.c. voltage is given by

Obviously, by varying thyristor ON/OFF ratio, VL can be made any percentage of the input d.c. voltage V.

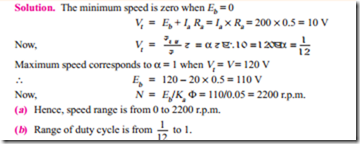

Example 30.48. The speed of a separately excited d.c. motor is controlled by a chopper. The supply voltage is 120 V, armature circuit resistance = 0.5 ohm, armature circuit inductance = 20 mH and motor constant = 0.05 V/r.p.m. The motor drives a constant load torque requiring an average current of 20 A. Assume motor current is continuous. Calculate (a) the range of speed control (b) the range of duty cycle. (Power Electronics-I, Punjab Univ. Nov. 1990)

Thyristor Inverters

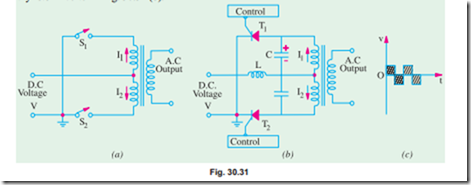

Such inverters provide a very efficient and economical way of converting direct current (or voltage) into alternating current (or voltage). In this application, a thyristor serves as a controlled switch alternately opening and closing a d.c. circuit. Fig. 30.31 (a), shows a basic inverter circuit where an a.c. output is obtained by alternately opening and closing switches S1 and S2. When we replace the mechanical switches by two thyristors (with their gate triggering circuits), we get the thyristor inverter in Fig. 30.31 (b).

Before discussing the actual circuit, it is worthwhile to recall that thyristor is a latching device which means that once it starts conducting, gate loses control over it and cannot switch it OFF what- ever the gate signal. A separate commutating circuitry is used to switch the thyristor OFF and thus enable it to perform ON-OFF switching function.

Suppose T1 is fired while T2 is still OFF. Immediately I1 is set up which flows through L, one half of transformer primary and T1. At the same time, C is charged with the polarity as shown.

Next when T2 is fired into condition, I2 is set up and C starts discharging through T1 thereby reverse- biasing it to CUT-OFF.

When T1 is again pulsed into condition, I1 is set up and C starts discharging thereby reverse-biasing T2 to OFF and the process just described repeats. As Second generation thyristor inverter shown in Fig. 30.31 (c), the output is an alternating voltage whose frequency depends on the switching frequency to thyristors T1 and T2.