Variable Reluctance Stepper Motors

Construction : A variable-reluctance motor is constructed from ferromagnetic material with salient poles as shown in Fig. 39.2. The stator is made from a stack of steel laminations and has six equally-spaced projecting poles (or teeth) each wound with an exciting coil. The rotor which may be solid or laminated has four projecting teeth of the same width as the stator teeth. As seen, there are three independent stator circuits or phases A , B and C and each one can be energised by a direct current pulse from the drive circuit (not shown in the figure).

A simple circuit arrangement for supplying current to the stator coils in proper sequence is shown in Fig.

(e). The six stator coils are connected in 2-coil groups to form three separate circuits called phases.

Each phase has its own independent switch.

Diametrically opposite pairs of stator coils are connected in series such that when one tooth becomes a N-pole, the other one becomes a S-pole. Although shown as mechanical switches in Fig. 39.2 (e), in actual practice, switching of phase currents is done with the help of solid-state control. When there is no current in the stator coils, the rotor is completely free to rotate. Energising one or more stator coils causes the rotor to step forward (or backward) to a position that forms a path of least reluctance with the magnetized stator teeth. The step angle of this three-phase, four rotor teeth motor is b = 360/ 4 ´ 3 = 30º.

Working. The motor has following modes of operation :

(a) 1-phase-ON or Full-step Operation

Fig. 39.2 (a) shows the position of the rotor when switch S1 has been closed for energising phase A . A magnetic field with its axis along the stator poles of phase A is created. The rotor is therefore, attracted into a position of minimum reluctance with diametrically opposite rotor teeth 1 and 3 lining up with stator teeth 1 and 4 respectively. Closing S2 and opening S1 energizes phase B causing rotor teeth 2 and 4 to align with stator teeth 3 and 6 respectively as shown in Fig. 39.2 (b). The rotor rotates through full-step of 30º in the clockwise (CW) direction. Similarly, when S3 is closed after opening S2, phase C is energized which causes rotor teeth 1 and 3 to line up with stator teeth 2 and 5 respectively as shown in Fig. 39.2 (c). The rotor rotates through an additional angle of 30º in the clockwise (CW) direction. Next if S3 is opened and S1 is closed again, the rotor teeth 2 and 4 will align with stator teeth 4 and 1 respectively thereby making the rotor turn through a further angle of 30º as shown in Fig. 39.2 (d). By now the total angle turned is 90º. As each switch is closed and the preceding one opened, the rotor each time rotates through an angle of 30º. By repetitively closing the switches in the sequence 1-2-3-1 and thus energizing stator phases in sequence ABCA etc., the rotor will rotate clockwise in 30º steps. If the switch sequence is made 3-2-1-3 which makes phase sequence CBAC (or ACB), the rotor will rotate anticlockwise. This mode of operation is known as 1-phase-ON mode or full-step operation and is the simplest and widely-used way of making the motor step. The stator phase switching truth table is shown in Fig. 39.2 (f). It may be noted that the direction of the stator magnetizing current is not significant because a stator pole of either magnetic polarity will always attract the rotor pole by inducing opposite polarity.

(b) 2-phase-ON Mode

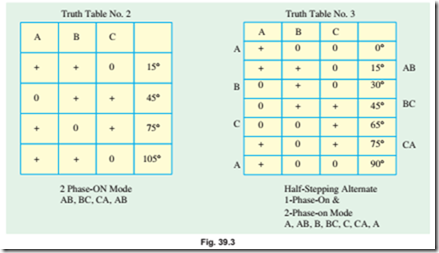

In this mode of operation, two stator phases are excited simultaneously. When phases A and B are energized together, the rotor experiences torques from both phases and comes to rest at a point mid-way between the two adjacent full-step positions. If the stator phases are switched in the sequence A B, BC, C A, AB etc., the motor will take full steps of 30º each (as in the 1-phase-ON mode) but its equilibrium positions will be interleaved between the full-step positions. The phase switching truth table for this mode is shown in Fig. 39.3 (a).

The 2-phase-ON mode provides greater holding torque and a much better damped single-stack response than the 1-phase-ON mode of operation.

(c) Half-step Operation

Half-step operation or ‘half-stepping’ can be obtained by exciting the three phases in the sequence A, AB, B, BC, C etc. i.e. alternately in the 1-phase-ON and 2-phase-ON modes. It is sometime known as ‘wave’ excitation and it causes the rotor to advance in steps of 15º i.e. half the full-step angle. The truth table for the phase pulsing sequence in half-stepping is shown in Fig. 39.3 (b).

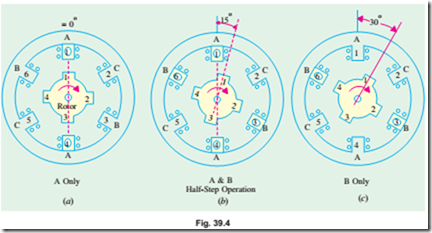

Half-stepping can be illustrated with the help of Fig. 39.4 where only three successive pulses have been considered. Energizing only phase A causes the rotor position shown in Fig. 39.4 (a). Energising phases A and B simultaneously moves the rotor to the position shown in Fig. 39.4 (b) where rotor has moved through half a step only. Energising only phase B moves the rotor through another half-step as shown in Fig. 39.4 (c). With each pulse, the rotor moves 30 / 2 = 15º in the CCW direction.

It will be seen that in half-stepping mode, the step angle is halved thereby doubling the resolution. Moreover, continuous half-stepping produces a smoother shaft rotation.

It is also known as mini-stepping. It utilizes two phases simultaneously as in 2-phase-ON mode but with the two currents deliberately made unequal (unlike in half-stepping where the two phase currents have to be kept equal). The current in phase A is held constant while that in phase B is increased in very small increments until maximum current is reached. The current in phase A is then reduced to zero using the same very small increments. In this way, the resultant step becomes very small and is called a microstep. For example, a VR stepper motor with a resolution of 200 steps / rev (b = 1.8º) can with microstepping have a resolution of 20,000 steps / rev (b = 0.018º). Stepper motors employing microstepping technique are used in printing and phototypesetting where very fine resolution is called for. As seen, microstepping provides smooth low-speed operation and high resolution.

Torque. If Ia is the d.c. current pulse passing through phase A, the torque produced by it is given dL / dq. VR stepper motors have a high (torque / inertia) ratio giving high rates of acceleration and fast response. A possible disadvantage is the absence of detent torque which is necessary to retain the rotor at the step position in the event of a power failure.

Related posts:

Incoming search terms:

- variable reluctance stepper motor

- variable reluctance stepper motor working principle

- variable reluctace stepper motar

- write material used in construction of variable reluctance stepper motor with salient poles

- disadvantage of variable reluctance stepper motor

- construction and principle of operation of variable reluctance stepper motor

- construction of variable reluctance stepper motor

- 2- phase- on mode of variable reluctance stepper motor

- various modes of excitation of variable reluctance motor

- variable reluctance stepper motor disadvantages

- variable reluctance stepper motor applications

- variable reluctance stepper motor truth table

- variable reluctance stepper applications

- variable reluctance motor torque produtiin

- Variable reluctance motor construction and working

- varia le reluctance stepper moyor 2 phase on mode

- variable reluctance stepper motor is made of ferromagnetic

- Working of Variable Reluctance Stepper motor

- variable ructance and stepper motors

- variable reluctance type stepper motor

- vr stepping motor on varoius mode construction

- variable reluctance stepper motortruthtable

- Variable Reluctance Stepper Motors

- with aid of labelled diagram an truth table describe the half-steps operation of a variable reluctance stepper motor in clockwise

- with help of truth table describe the half-step operation of variable reluctance stepper motor in clockwise direction

- variable reluctance stepper motor two phase on mode

- truth table of stepper motor

- torque production in vr stepper motor

- torque production in variable reluctance stepper motor

- different modes of excitation in stepper motor

- construction of vr steepers motor

- construction of reluctance stepper motor

- construction and working of variable reluctance stepper motor with application

- construction and working and mode of operation of variable reluctance stepper motor

- 2 modes of operating a variable reluctance stepper motor

- applications of variable reluctance stepper motor

- Application of variable reluctance stepper motor

- application of variable reluctance of multi stack

- disadvantage of variable reluctance steeper motor

- half step operation of vr stepper motor

- how ministepping is achieved in variable reluctance stepper motor

- torque produced in variable reluctance stepper motor

- Torque produce by variable reluctant motor

- TORQUE CONTROL OF A MULTI-STACK VARIABLE RELUCTANCE STEPPER MOTOR USING CYCLO-CONVERTERS

- stepper motor truth table

- steeper motor 2 phase on truth table

- operation of variables reluctant stepper motor

- mode of operation of variable reluctance motor

- mode of operation in variable reluctance stepper motor

- material used for construction of variable reluctance motor