Permanent-Magnet DC Motor

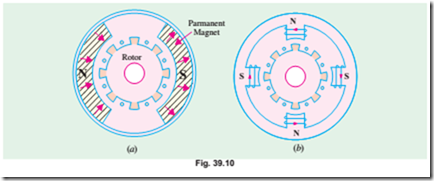

A permanent-magnet d.c. (PMDC) motor is similar to an ordinary d.c. shunt motor except that its field is provided by permanent magnets instead of salient-pole wound-field structure. Fig. 39.10 (a) shows 2-pole PMDC motor whereas Fig. 39.10 (b) shows a 4-pole wound-field motor for comparison purposes.

(a) Construction

As shown in Fig. 39.10 (a), the permanent magnets of the PMDC motor are supported by a cylindrical steel stator which also serves as a return path for the magnetic flux. The rotor (i.e. armature) has winding slots, commutator segments and brushes as in conventional d.c. machines.

There are three types of permanent magnets used for such motors. The materials used have residual flux density and high coercivity.

(i) Alnico magnets – They are used in motors having ratings in the range of 1 kW to 150 kW.

(ii) Ceramic (ferrite) magnets – They are much economical in fractional kilowatt motors.

(iii) Rare-earth magnets – Made of samarium cobalt and neodymium iron cobalt which have the highest energy product. Such magnetic materials are costly but are best economic choice for small as well as large motors.

Another form of the stator construction is the one in which permanent-magnet material is cast in the form of a continuous ring instead of in two pieces as shown in Fig. 39.10 (a).

(b) Working

Most of these motors usually run on 6 V, 12 V or 24 V dc supply obtained either from batteries or rectified alternating current. In such motors, torque is produced by interaction between the axial current-carrying rotor conductors and the magnetic flux produced by the permanent magnets.

(c) Performance

curves for such a motor. Its speed-torque curve is a straight line which makes this motor ideal for a servomotor. Moreover, input current increases linearly with load torque. The efficiency of such motors is higher as compared to wound-field dc motors because, in their case, there is no field Cu loss.

(d) Speed Control

Since flux remains constant, speed of a PMDC motor cannot be controlled by using Flux Control Method (Art 33.2). The only way to control its speed is to vary the armature voltage with the help of an armature rheostat (Art 33.2) or electronically by 0 using x-choppers. Consequently, such motors are found in systems where speed control below base speed only is required.

(e) Advantages

(i) In very small ratings, use of permanent-magnet excitation results in lower manufacturing cost.

(ii) In many cases a PMDC motor is smaller in size than a wound-field d.c. motor of equal power rating.

(iii) Since field excitation current is not required, the efficiency of these motors is generally higher than that of the wound-field motors.

(iv) Low-voltage PMDC motors produce less air noise.

(v) When designed for low-voltage (12 V or less) these motors produced very little radio and TV interference.

(f) Disadvantages

(i) Since their magnetic field is active at all times even when motor is not being used, these motors are made totally enclosed to prevent their magnets from collecting magnetic junk from neighbourhood. Hence, as compared to wound-field motors, their temperature tends to be higher. However, it may not be much of a disadvantage in situations where motor is used for short intervals.

(ii) A more serious disadvantage is that the permanent magnets can be demagnetized by armature reaction mmf causing the motor to become inoperative. Demagnetization can result from (a) improper design (b) excessive armature current caused by a fault or transient or improper connection in the armature circuit (c) improper brush shift and (d) temperature effects.

(g) Applications

(i) Small, 12-V PMDC motors are used for driving automobile heater and air conditioner blowers, windshield wipers, windows, fans and radio antennas etc. They are also used for electric fuel pumps, marine engine starters, wheelchairs and cordless power tools.

(ii) Toy industry uses millions of such motors which are also used in other appliances such as the toothbrush, food mixer, ice crusher, portable vacuum cleaner and shoe polisher and also in portable electric tools such as drills, saber saws and hedge trimmers etc.

Low-inertia DC Motors

These motors are so designed as to make their armature mass very low. This permits them to start, stop and change direction and speed very quickly making them suitable for instrumentation applications. The two common types of low-inertia motors are (i) shell-type motor and (ii) printed- circuit (PC) motor.

Shell-type Low-intertia DC Motor

Its armature is made up of flat aluminium or copper coils bonded together to form a hollow cylinder as shown in Fig. 39.12. This hollow cylinder is not attached physically to its iron core which is stationary and is located inside the shell-type rotor. Since iron does not form part of the rotor, the rotor inertia is very small.