Reluctance Motor

It has either the conventional split-phase stator and a centrifugal switch for cutting out the auxiliary winding (split-phase type reluctance motor) or a stator similar to that of a permanent-split capacitor-run motor (capacitor-type reluctance motor). The stator produces the revolving field.

The squirrel-cage rotor is of unsymmetrical magnetic construction. This type of unsymmetrical construction can be achieved by removing some of the teeth of a symmetrical squirrel-cage rotor punching. For example, in a 48-teeth, four-pole rotor following teeth may be cut away :

1, 2, 3, 4, 5, 6 – 13, 14, 15, 16, 17, 18 – 25, 26, 27, 28, 29, 30 – 37, 38, 39, 40, 41, 42.

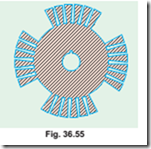

This would leave four projecting or salient poles (Fig. 36.55) consisting of the following sets of teeth : 7–12; 19–24; 31–36 and 43 – 48. In this way, the rotor offers variable magnetic reluctance to the stator flux, the reluctance varying with the position of the rotor.

Working

For understanding the working of such a motor one basic fact must be kept in mind. And it is that when a piece of magnetic material is located in a magnetic field, a force acts on the material, tending to bring it into the most dense portion of the field. The force tends to align the specimen of material in such a way that the reluctance of the magnetic path that lies through the material will be minimum.

When the stator winding is energised, the revolving magnetic field exerts reluctance torque on the unsymmetrical rotor tending to align the salient pole axis of the rotor with the axis of the revolving magnetic field (because in this position, the reluctance of the magnetic path is minimum). If the reluctance torque is sufficient to start the motor and its load, the rotor will pull into step with the revolving field and continue to run at the speed of the revolving field.*

However, even though the rotor revolves synchronously, its poles lag behind the stator poles by a certain angle known as torque angle, (something similar to that in a synchronous motor). The reluctance torque increases with increase in torque angle, attaining maximum value when a = 45º. If a increases beyond 45º, the rotor falls out of synchronism. The average value of the reluctance torque is given by T = K (V /f)2 sin2 d where K is a motor constant.

It may be noted that the amount of load which a reluctance motor could carry at its constant speed would only be a fraction of the load that the motor could normally carry when functioning as an induction motor. If the load is increased beyond a value under which the reluctance torque cannot maintain synchronous speed, the rotor drops out of step with the field. The speed, then, drops to some value at which the slip is sufficient to develop necessary torque to drive the load by induction-motor action.

The constant-speed characteristic of a reluctance motor makes it very suitable for such applications as signalling devices, recording instruments, many kinds of timers and phonographs etc.