Armature Torque of a Motor

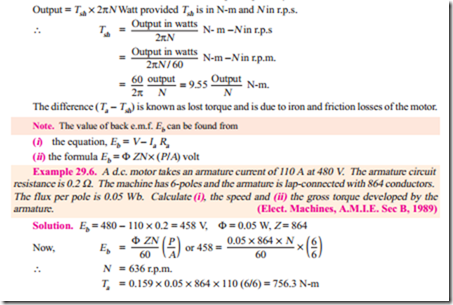

Let Ta be the torque developed by the armature of a motor running at N r.p.s. If Ta is in N/M, then power developed = Ta ´ 2p N watt

Shaft Torque

The whole of the armature torque, as calculated above, is not available for doing useful work, because a certain percentage of it is required for supplying iron and friction losses in the motor.

The torque which is available for doing useful work is known as shaft torque Tsh. It is so called because it is available at the shaft. The motor output is given by

Example 29.7. A 250-V, 4-pole, wave-wound d.c. series motor has 782 conductors on its armature. It has armature and series field resistance of 0.75 ohm. The motor takes a current of 40 A. Estimate its speed and gross torque developed if it has a flux per pole of 25 mWb.

Since, the terminal voltage is same in both the cases, shunt field current remains as 2.5 amp. With armature reaction is ignored, the flux/pole remains same. The e.m.f. then becomes proportional to the speed. If the generator must be driven at N r.p.m.

Example 29.15. The armature winding of a 200-V, 4-pole, series motor is lap-connected. There are 280 slots and each slot has 4 conductors. The current is 45 A and the flux per pole is 18 mWb. The field resistance is 0.3 W; the armature resistance 0.5 W and the iron and friction losses total 800 W. The pulley diameter is 0.41 m. Find the pull in newton at the rim of the pulley.

(Elect. Engg. AMIETE Sec. A. 1991)

Example 29.18. A 460-V, 55.95 kW, 750 r.p.m. shunt motor drives a load having a moment of inertia of 252.8 kg-m2. Find approximate time to attain full speed when starting from rest against full-load torque if starting current varies between 1.4 and 1.8 times full-load current.

Solution. Let us suppose that the starting current has a steady value of (1.4 + 1.8)/2 = 1.6 times full-load value.