Gas Turbine Cycles with Regeneration and Reheat

Regenerative Brayton Cycle

We return to the discussion of the Brayton cycle, which was introduced in Sec. 10.5. As is evident from the discussion there, in particular from the T-s- diagram, the Brayton cycle expels rather warm exhaust into the environment. Since the exhaust is warmer than the environment, it has a work potential as was shown in Sec. 11.6. If the exhaust is just blown into the environment, this work potential remains unused. The ensuing equilibration between exhaust and environment is an irreversible process—it is an external irreversibility for the gas turbine.

To recover at least a portion of the exhaust work potential, the exhaust can be lead through a regenerator to heat the compressed air before it enters the combustion chamber. With this, less heat must be supplied from the outside, and the efficiency is increased.

Figure 13.9 shows schematic and T-s-diagram for a Brayton gas turbine cycle with regenerator, which is a counter-flow heat exchanger. Since heat

goes from warm to cold, the preheat temperature Tx cannot be larger than the turbine exhaust temperature T4, while the final exhaust temperature Ty cannot be smaller than T2. Thus, the use of a regenerator makes only sense when the turbine exhaust temperature T4 is larger than the temperature after compression, T2.

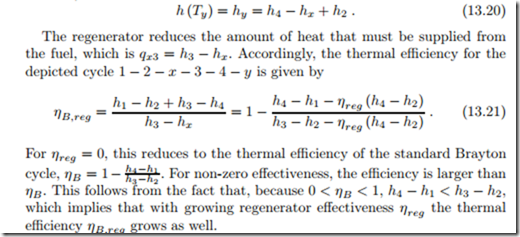

A perfect heat exchanger would yield Tx = T4 and this is used to define the regenerator effectiveness as3

A 100% effective regenerator would transfer heat at infinitesimal temperature differences, a realistic regenerator operates with finite temperature differences and around 80% effectiveness. The exhaust temperature Ty follows from the energy balance over the regenerator, assuming that no heat is lost to the exterior, as

The actual improvement depends on the detailed data of the process.

Example: Brayton Cycle with Regenerator

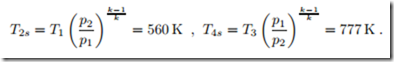

The impact of the regenerator is best studied by means of examples. We con- sider a Brayton cycle with compressor inlet temperature T1 = 290 K, turbine inlet temperature T3 = 1500K, and pressure ratio p2/p1 = 10. To simplify the computation, we rely on the cold-air approximation with k = cp = 1.4, R, which gives the temperatures after isentropic compressor and turbine as

First, we consider the fully reversible cycle, with 100% effective regenera- tor. For this, according to (13.19, 13.20), the preheat temperature after the regenerator is Tx = T4s, and the exhaust temperature is Ty = T2s. With the computed temperatures, we find the specific work of the reversible cycle as

We see that a regenerator can give substantial improvement for cycle efficiency.

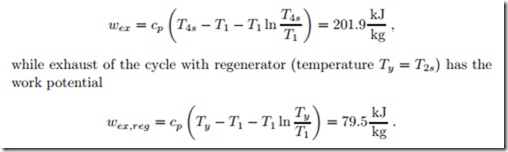

With the regenerator, the external loss is reduced, since the exhaust temperature, and thus the external irreversibility, is lowered considerably. Indeed, the exhaust of the cycle without regenerator (temperature Tx = T4s) has the work potential

Recall that the work potential of the exhaust is lost, since the exhaust is dumped into the environment. For this example, the regenerator reduces the exhaust loss by about 60%.

All efficiency values in the above example are relatively high, since no internal irreversibilities are accounted for. To study how internal irreversibilities affect the results, we now assume isentropic efficiencies for compressor and turbine of ηT = ηC = 0.85, and a regenerator effectiveness of ηreg = 0.8.

Then, we find the temperatures after compressor and turbine as

Nevertheless, the exhaust still has significant work potential, which is about 50% of the work actually delivered by the system. Another heat engine can be used to produce work from the exhaust—see the discussion of the combined cycle further below.

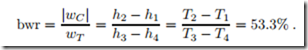

For motivation of the next section we compute the ratio between compressor and turbine work, i.e., the back work ratio, for this cycle as