Combined Cycle

As we have seen, even in a gas turbine with regeneration there are significant exhaust losses. An alternative to regeneration is using the gas turbine exhaust to provide heat for another heat engine. In the combined cycle the gas turbine exhaust is used in a heat recovery steam generator (HSRG) to provide heat for a steam power cycle. Figure 13.11 shows schematic and energy flow diagram for the combination of a standard Brayton cycle with a standard Rankine cycle. Real power plants use state of the art regenerative steam cycles (see Section 12.2).4

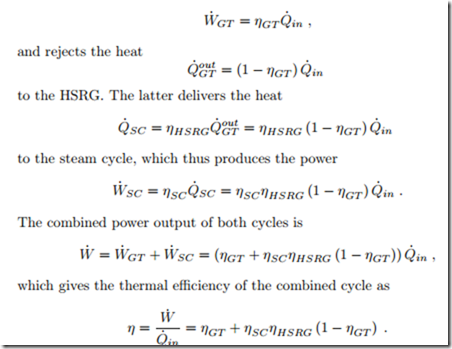

In order to evaluate the combined cycle, we consider a gas turbine cycle with thermal efficiency ηGT and a steam cycle with thermal efficiency ηSC , which are connected by an HSRG with effectiveness ηHSRG.

The heat into the system from combustion in the gas turbine is Q˙ in. The gas turbine cycle produces the work

The efficiency of the combined cycle is always greater than the efficiency of the gas turbine alone (unless ηHSRG = 0), and is also larger than the efficiency of the steam cycle alone as long as ηHSRG is large enough (in particular η > ηSC if ηHRSG = 1).

A gas turbine with ηGT = 0.31 combined with a steam cycle of ηSC = 0.45 by means of a HRSG with ηHRSG = 0.9 has an overall efficiency of 60%.

Indeed, combined cycle power plants have the highest available efficiencies among all combustion driven power plants. They allow large upper temperatures in the gas turbines, and reject heat at relatively low temperatures.

The only drawback to their use is that they require gaseous or liquid fuels, and cannot be fed directly with coal. Recall that the average efficiency of the World’s combustion power plants is about 35% or less. Much better use of fossil fuels could be made by using coal gasification or liquefaction and combined cycle plants.