Introduction

Most transient disturbances that a facility will experience enter the plant through the utility company ac power line. Effective transient suppression, therefore, begins with proper installation of the ac power-system wiring. If possible, arrange with the local utility to have a separate transformer feed the facility. The initial cost may be higher, but it will reduce the chances that transient disturbances from nearby operations will affect sensitive equipment. Do not allow the placement of noisy loads on the facility power line. Devices such as arc-welders, heavy electric motors, elevators, and other large loads can create an electrical environment that is prone to equipment malfunctions. It should be noted, however, that because transient disturbances, by definition, are high-frequency events, they will capacitively couple from the primary to the secondary of a typical utility company transformer. Simply installing a dedicated transformer that is not equipped with a Faraday shield (utility transformers generally do not have such shields) will not, in itself, protect equipment from potential damage. Installation of a dedicated utility transformer, however, will reduce the likelihood of problems and permit the establishment of a facility ground system independent of other users.

Facility Wiring

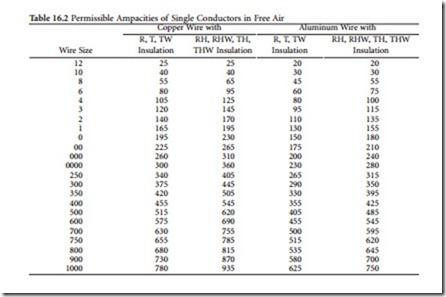

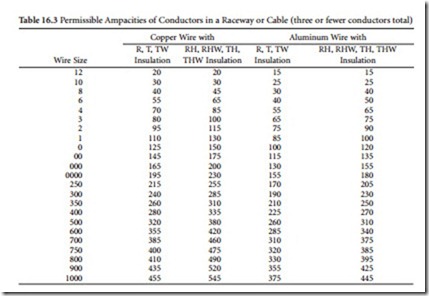

All ac wiring within a facility should be performed by an experienced electrical contractor and always fully within the local electrical code. Confirm that all wiring is sized properly for the load current. Table 16.1 lists the physical characteristics for various wire sizes. The current-carrying capability (ampacity) of single con- ductors in free air is listed in Table 16.2. The ampacity of conductors in a raceway or cable (three or fewer conductors) is listed in Table 16.3.

Synthetic insulation for wire and cable is classified into two broad categories: (1) thermosetting, and (2) thermoplastic. A wide variety of chemical mixtures can be found within each category. Most insulation is com- posed of compounds made from synthetic rubber polymers (thermosetting) and from synthetic materials (thermoplastics). Various materials are combined to provide specific physical and electrical properties. Ther- mosetting compounds are characterized by their ability to be stretched, compressed, or deformed within rea- sonable limits under mechanical stress and then to return to their original shape when the stress is removed. Thermoplastic insulation materials are best known for their electrical characteristics and relatively low cost. Thermoplastics permit insulation thickness to be reduced while maintaining good electrical properties.

Many different types of insulation are used for electric conductors. The operating conditions determine the type of insulation used. Insulation types are identified by abbreviations established in the National Elec- trical Code (NEC). The most popular types are

• R: Rubber, rated for 140°F

• RH: Heat-resistant rubber, rated for 167°F

• RHH: Heat-resistant rubber, rated for 194°F

• RHW: Moisture- and heat-resistant rubber, rated for 167°F

• T: Thermoplastic, rated for 140°F

• THW: Moisture- and heat-resistant thermoplastic, rated for 167°F

• THWN: Moisture- and heat-resistant thermoplastic with nylon, rated for 194°F

Utility Service Entrance

Figure 16.1 shows a typical service entrance, with the neutral line from the utility company tied to ground and to a ground rod at the meter panel. Where permitted by the local code, this should be the only point at which neutral is tied to ground in the ac distribution system.

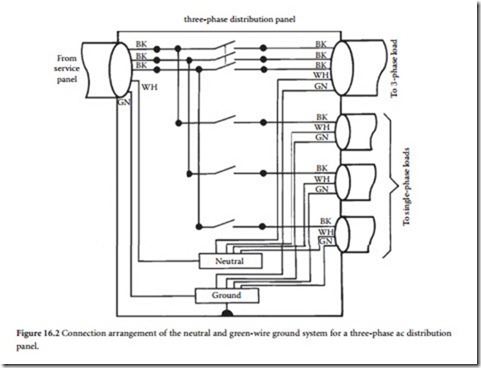

Figure 16.2 shows a three-phase power-distribution panel. Note that the neutral and ground connections are kept separate. Most ac distribution panels give the electrical contractor the ability to lift the neutral from ground by removing a short-circuiting screw in the breaker-panel chassis. Where permitted by local code, insulate the neutral lines from the cabinet. Bond the ground wires to the cabinet for safety. Always run a separate, insulated green wire for ground. Never rely on conduit or other mechanical structures to provide an ac system ground to electric panels or equipment.

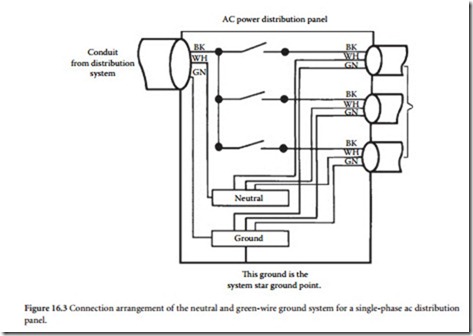

A single-phase power-distribution panel is shown in Figure 16.3. Note that neutral is insulated from ground and that the insulated green ground wires are bonded to the panel chassis.

Conduit runs often are a source of noise. Corrosion of the steel-to-steel junctions can act as an RF detector. Conduit feeding sensitive equipment may contact other conduit runs powering noisy devices, such as elevators or air conditioners. Where possible (and permitted by the local code), eliminate this problem by using PVC pipe, Romex, or jacketed cable. If metal pipe must be used, send the noise to the power ground rods by isolating the green ground wire from the conduit with a ground-isolating (orange) receptacle. When using an orange receptacle, a second ground wire is required to bond the enclosure to the ground system, as shown in Figure 16.4. In a new installation, isolate the conduit from building metal structures or other conduit runs. Consult the local electrical code and an experienced electrical contractor before installing or modifying any ac power-system wiring. Make sure to also secure any necessary building permits for such work.