Factors Affecting Alternator Size

The efficiency of an alternator always increases as its power increases. For example, if an alternator of 1 kW has an efficiency of 50%, then one of 10 MW will inevitably have an efficiency of about 90%. It is because of this improvement in efficiency with size that alternators of 1000 MW and above possess efficiencies of the order of 99%.

Another advantage of large machines is that power output per kilogram increases as the alternator power increases. If 1 kW alternator weighs 20 kg (i.e. 50 W/kg), then 10MW alternator weighing 20,000 kg yields 500 W/kg. In other words, larger alterna- tors weigh relatively less than smaller ones and are, consequently, cheaper.

However, as alternator size increases, cooling problem becomes more serious.

Since large machines inherently produce high power loss per unit surface area (W/m2), they tend to overheat.

To keep the temperature rise within acceptable limits, we have to design efficient cooling system which becomes ever more elaborate as the power increases. For cooling alternators of rating upto 50 MW, circulating cold-air system is adequate but for those of rating between 50 and 300 MW, we have to resort to hydrogen cooling. Very big machines in 1000 MW range have to be equipped with hollow water-cooled conductors. Ultimately, a point is reached where increased cost of cooling exceeds the saving made elsewhere and this fixes the upper limit of the alternator size.

So for as the speed is concerned, low-speed alternators are always bigger than high speed alternators of the same power. Bigness always simplifies the cooling

problem. For example, the large 200-rpm, 500-MVA alternators installed in a typical hydropower plant are air-cooled whereas much smaller 1800-r.p.m., 500-MVA alternators installed in a steam plant are hydrogen cooled.

Alternator on Load

As the load on an alternator is varied, its terminal voltage is also found to vary as in d.c. generators. This variation in terminal voltage V is due to the following reasons:

1. voltage drop due to armature resistance Ra

2. voltage drop due to armature leakage reactance XL

3. voltage drop due to armature reaction

(a) Armature Resistance

The armature resistance/phase Ra causes a voltage drop/phase of IRa which is in phase with the armature current I. However, this voltage drop is practically negligible.

(b) Armature Leakage Reactance

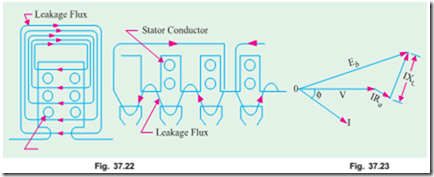

When current flows through the armature conductors, fluxes are set up which do not cross the air-gap, but take different paths. Such fluxes are known as leakage fluxes. Various types of leakage fluxes are shown in Fig. 37.22.

The leakage flux is practically independent of saturation, but is dependent on I and its phase angle with terminal voltage V. This leakage flux sets up an e.m.f. of self-inductance which is known as reactance e.m.f. and which is ahead of I by 90°. Hence, armature winding is assumed to possess leakage reactance XL (also known as Potier rectance XP) such that voltage drop due to this equals IXL. A part of the generated e.m.f. is used up in overcoming this reactance e.m.f.

This fact is illustrated in the vector diagram of Fig. 37.23.

(c) Armature Reaction

As in d.c. generators, armature reaction is the effect of armature flux on the main field flux. In the case of alternators, the power factor of the load has a considerable effect on the armature reaction. We will consider three cases :

(i) when load of p.f. is unity

(ii) when p.f. is zero lagging and

(iii) when p.f. is zero leading.

Before discussing this, it should be noted that in a 3-phase machine the combined ampere-turn wave (or m.m.f. wave) is sinusoidal which moves synchronously. This amp-turn or m.m.f. wave is fixed relative to the poles, its amplitude is proportional to the load current, but its position depends on the p.f. of the load.

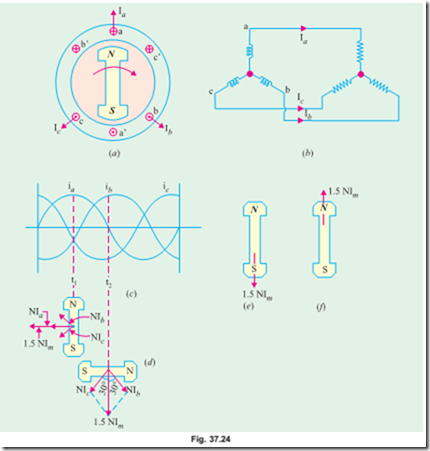

Consider a 3-phase, 2-pole alternator having a single-layer winding, as shown in Fig. 37.24 (a). For the sake of simplicity, assume that winding of each phase is concentrated (instead of being distributed) and that the number of turns per phase is N. Further suppose that the alternator is loaded with a resistive load of unity power factor, so that phase currents Ia, Ib and Ic are in phase with their respective phase voltages. Maximum current Ia will flow when the poles are in position shown in Fig.

(a) or at a time t1 in Fig. 37.24 (c). When Ia has a maximum value, Ib and Ic have one-half their maximum values (the arrows attached to Ia , Ib and Ic are only polarity marks and are not meant to give the instantaneous directions of these currents at time t1). The instantaneous directions of currents are shown in Fig. 37.24 (a). At the instant t1, Ia flows in conductor a whereas Ib and Ic flow out.

As seen from Fig. 37.24 (d), the m.m.f. (= NIm) produced by phase a–a¢ is horizontal, whereas that produced by other two phases is (Im/2) N each at 60° to the horizontal. The total armature m.m.f. is equal to the vector sum of these three m.m.fs.

Armature m.m.f. = NIm + 2.(1/2 NIm) cos 60° = 1.5 NIm

As seen, at this instant t1, the m.m.f. of the main field is upwards and the armature m.m.f. is behind it by 90 electrical degrees.

Next, let us investigate the armature m.m.f. at instant t2. At this instant, the poles are in the horizontal position. Also Ia = 0, but Ib and Ic are each equal to 0.866 of their maximum values. Since Ic has not changed in direction during the interval t1 to t2, the direction of its m.m.f. vector remains unchanged. But Ib has changed direction, hence, its m.m.f. vector will now be in the position shown in Fig. 37.24 (d). Total armature m.m.f. is again the vector sum of these two m.m.fs.

Armature m.m.f. = 2 ´ (0.866 NIm) ´ cos 30° = 1.5 NIm. If further investigations are made, it will be found that.

1. armature m.m.f. remains constant with time

2. it is 90 space degrees behind the main field m.m.f., so that it is only distortional in nature.

3. it rotates synchronously round the armature i.e. stator.

For a lagging load of zero power factor, all currents would be delayed in time 90° and armature m.m.f. would be shifted 90° with respect to the poles as shown in Fig. 37.24 (e). Obviously, armature m.m.f. would demagnetise the poles and cause a reduction in the induced e.m.f. and hence the terminal voltage.

For leading loads of zero power factor, the armature m.m.f. is advanced 90° with respect to the position shown in Fig. 37.24 (d). As shown in Fig. 37.24 (f), the armature m.m.f. strengthens the main

In this case, armature reaction is wholly magnetising and causes an increase in the terminal voltage.

The above facts have been summarized briefly in the following paragraphs where the matter is discussed in terms of ‘flux’ rather than m.m.f. waves.

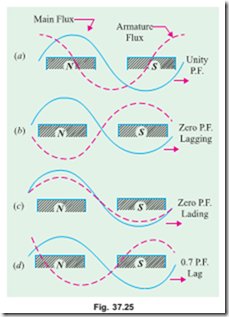

1. Unity Power Factor

In this case [Fig. 37.25 (a)] the armature flux is cross-magnetising. The result is that the flux at the leading tips of the poles is reduced while it is increased at the trailing tips. However, these two effects nearly offset each other leaving the average field strength constant. In other words, armature reaction for unity p.f. is distortional.

2. Zero P.F. lagging

As seen from Fig. 37.25 (b), here the arma- ture flux (whose wave has moved backward by 90°) is in direct opposition to the main flux.

Hence, the main flux is decreased. Therefore, it is found that armature reaction, in this case, is wholly demagnetising, with the result, that due to weakening of the main flux, less e.m.f. is generated. To keep the value of generated e.m.f. the same, field excitation will have to be increased to compensate for this weakening.

3. Zero P.F. leading

In this case, shown in Fig. 37.25 (c) armature flux wave has moved forward by 90° so that it is in

phase with the main flux wave. This results in added main flux. Hence, in this case, armature reaction is wholly magnetising, which results in greater induced e.m.f. To keep the value of generated e.m.f. the same, field excitation will have to be reduced somewhat.

4. For intermediate power factor [Fig. 37.25 (d)], the effect is partly distortional and partly demagnetising (because p.f. is lagging).