GENERATOR CONSTRUCTION

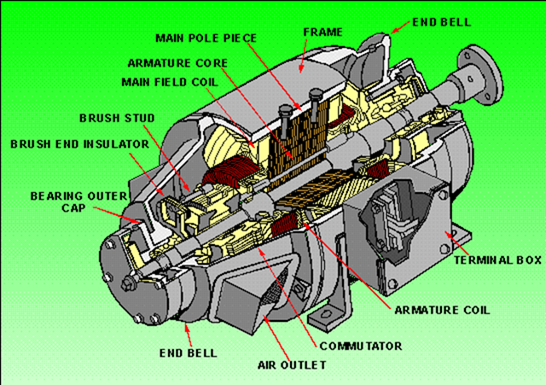

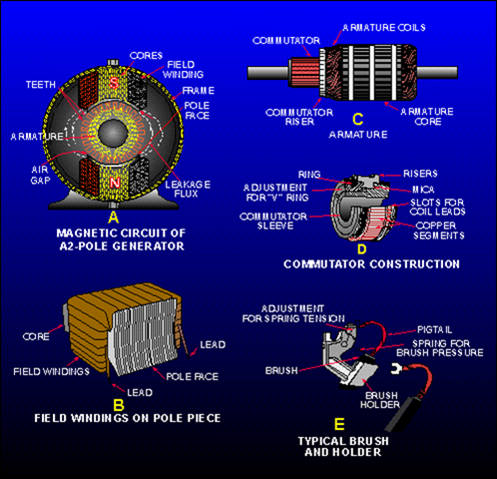

Figure 1-19, views A through E, shows the component parts of dc generators. Figure 1-20 shows the entire generator with the component parts installed. The cutaway drawing helps you to see the physical relationship of the components to each other.

Figure 1-19. – Components of a dc generator.

Figure 1-20. – Construction of a dc generator (cutaway drawing).

VOLTAGE REGULATION

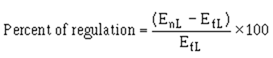

The regulation of a generator refers to the VOLTAGE CHANGE that takes place when the load changes. It is usually expressed as the change in voltage from a no-load condition to a full-load condition, and is expressed as a percentage of full-load. It is expressed in the following formula:

where EnL is the no-load terminal voltage and EfL is the full-load terminal voltage of the generator. For example, to calculate the percent of regulation of a generator with a no-load voltage of 462 volts and a full-load voltage of 440 volts

Given:

No-load voltage 462 V

Full-load voltage 440 V

Solution:

NOTE: The lower the percent of regulation, the better the generator. In the above example, the 5% regulation represented a 22-volt change from no load to full load. A 1% change would represent a change of 4.4 volts, which, of course, would be better.

Q.20 What term applies to the voltage variation from no-load to full-load conditions and is expressed as a percentage?

Back

Home

Up

Next

VOLTAGE CONTROL

Voltage control is either (1) manual or (2) automatic. In most cases the process involves changing the resistance of the field circuit. By changing the field circuit resistance, the field current is controlled. Controlling the field current permits control of the output voltage. The major difference between the various voltage control systems is merely the method by which the field circuit resistance and the current are controlled.

VOLTAGE REGULATION should not be confused with VOLTAGE CONTROL.

As described previously, voltage regulation is an internal action occurring within the generator whenever the load changes. Voltage control is an imposed action, usually through an external adjustment, for the purpose of increasing or decreasing terminal voltage.

Manual Voltage Control

The hand-operated field rheostat, shown in figure 1-21,is a typical example of manual voltage control. The field rheostat is connected in series with the shunt field circuit. This provides the simplest method of controlling the terminal voltage of a dc generator.

Figure 1-21. – Hand-operated field rheostat.

This type of field rheostat contains tapped resistors with leads to a multiterminal switch. The arm of the switch may be rotated to make contact with the various resistor taps. This varies the amount of resistance in the field circuit. Rotating the arm in the direction of the LOWER arrow (counterclockwise) increases the resistance and lowers the output voltage. Rotating the arm in the direction of the RAISE arrow (clockwise) decreases the resistance and increases the output voltage.

Most field rheostats for generators use resistors of alloy wire. They have a high specific resistance and a low temperature coefficient. These alloys include copper, nickel, manganese, and chromium. They are marked under trade names such as Nichrome, Advance, Manganin, and so forth. Some very large generators use cast-iron grids in place of rheostats, and motor-operated switching mechanisms to provide voltage control.

Automatic Voltage Control

Automatic voltage control may be used where load current variations exceed the built-in ability of the generator to regulate itself. An automatic voltage control device "senses" changes in output voltage and causes a change in field resistance to keep output voltage constant.

The actual circuitry involved in automatic voltage control will not be covered in this chapter. Whichever control method is used, the range over which voltage can be changed is a design characteristic of the generator. The voltage can be controlled only

PARALLEL OPERATION OF GENERATORS

When two or more generators are supplying a common load, they are said to be operating in parallel. The purpose of connecting generators in parallel is simply to provide more current than a single generator is capable of providing. The generators may be physically located quite a distance apart. However, they are connected to the common load through the power distribution system.

There are several reasons for operating generators in parallel. The number of generators used may be selected in accordance with the load demand. By operating each generator as nearly as possible to its rated capacity, maximum efficiency is achieved. A disabled or faulty generator may be taken off-line and replaced without interrupting normal operations.

Q.21 What term applies to the use of two or more generators to supply a common load?

Back

Home

Up

Next

AMPLIDYNES

Amplidynes are special-purpose dc generators. They supply large dc currents, precisely controlled, to the large dc motors used to drive heavy physical loads, such as gun turrets and missile launchers.

The amplidyne is really a motor and a generator. It consists of a constant-speed ac motor (the prime mover) mechanically coupled to a dc generator, which is wired to function as a high-gain amplifier (an amplifier is a device in which a small input voltage can control a large current source). For instance, in a normal dc generator, a small dc voltage applied to the field windings is able to control the output of the generator. In a typical generator, a change in voltage from 0-volt dc to 3-volts dc applied to the field winding may cause the generator output to vary from 0-volt dc to 300-volts dc. If the 3 volts applied to the field winding is considered an input, and the 300 volts taken from the brushes is an output, there is a gain of 100. Gain is expressed as the ratio of output to input:

![]()

In this case 300 V ÷ 3 V = 100. This means that the 3 volts output is 100 times larger than the input.

The following paragraphs explain how gain is achieved in a typical dc generator and how the modifications making the generator an amplidyne increase the gain to as high as 10,000.

The schematic diagram in figure 1-22 shows a separately excited dc generator. Because of the 10-volt controlling voltage, 10 amperes of current will flow through the 1-ohm field winding. This draws 100 watts of input power (P = IE).

Figure 1-22. – Ordinary dc generator.

Assume that the characteristics of this generator enable it to produce approximately 87 amperes of armature current at 115 volts at the output terminals. This represents an output power of approximately 10,000 watts (P = IE). You can see that the power gain of this generator is 100. In effect, 100 watts controls 10,000 watts.

An amplidyne is a special type of dc generator. The following changes, for explanation purposes, will convert the typical dc generator above into an amplidyne.

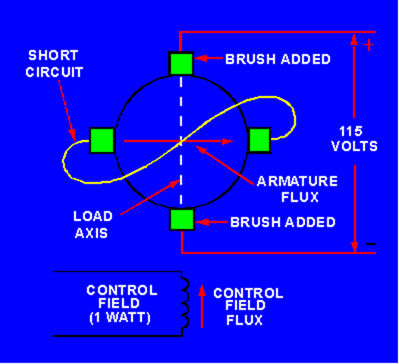

The first step is to short the brushes together, as shown in figure 1-23. This removes nearly all of the resistance in the armature circuit.

Figure 1-23. – Brushes shorted in a dc generator.

Because of the very low resistance in the armature circuit, a much lower control-field flux produces full-load armature current (full-load current in the armature is still about 87 amperes). The smaller control field now requires a control voltage of only 1 volt and an input power of 1 watt (1 volt across 1 ohm causes 1 ampere of current, which produces 1 watt of input power).

The next step is to add another set of brushes. These now become the output brushes of the amplidyne. They are placed against the commutator in a position perpendicular to the original brushes, as shown in figure 1-24. The previously shorted brushes are now called the "quadrature" brushes. This is because they are in quadrature (perpendicular) to the output brushes. The output brushes are in line with the armature flux. Therefore, they pick off the voltage induced in the armature windings at this point. The voltage at the output will be the same as in the original generator, 115 volts in our example.

Figure 1-24. – Amplidyne load brushes.

As you have seen, the original generator produced a 10,000-watt output with a 100-watt input. The amplidyne produces the same 10,000-watt output with only a 1-watt input. This represents a gain of 10,000. The gain of the original generator has been greatly increased.

As previously stated, an amplidyne is used to provide large dc currents. The primary use of an amplidyne is in the positioning of heavy loads through the use of synchro/servo systems. Synchro/servo systems will be studied in a later module.

Assume that a very large turning force is required to rotate a heavy object, such as an antenna, to a very precise position. A low-power, relatively weak voltage representing the amount of antenna rotation required can be used to control the field winding of an amplidyne. Because of the amplidyne’s ability to amplify, its output can be used to drive a powerful motor, which turns the heavy object (antenna). When the source of the input voltage senses the correct movement of the object, it drops the voltage to zero. The field is no longer strong enough to allow an output voltage to be developed, so the motor ceases to drive the object (antenna).

The above is an oversimplification and is not meant to describe a functioning system. The intent is to show a typical sequence of events between the demand for movement and the movement itself. It is meant to strengthen the idea that with the amplidyne, something large and heavy can be controlled very precisely by something very small, almost insignificant.

Q.22 What is the purpose of a dc generator that has been modified to function as an amplidyne?

Q.23 What is the formula used to determine the gain of an amplifying device?Q.24 What are the two inputs to an amplidyne?

Back

Home

Up

Next

SAFETY PRECAUTIONS

You must always observe safety precautions when working around electrical equipment to avoid injury to personnel and damage to equipment. Electrical equipment frequently has accessories that require separate sources of power. Lighting fixtures, heaters, externally powered temperature detectors, and alarm systems are examples of accessories whose terminals must be deenergized. When working on dc generators, you must check to ensure that all such circuits have been de-energized and tagged before you attempt any maintenance or repair work. You must also use the greatest care when working on or near the output terminals of dc generators.

Back

Home

Up

Next