Ericsson Cycle

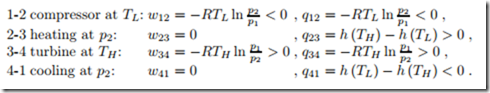

The Stirling cycle operates in piston-cylinder assemblies, in closed systems. The Ericsson cycle is very similar, only that it consists of open system devices, namely isothermal turbine and compressor, and isobaric heat exchangers; again, the working fluid is an ideal gas. Figure 13.5 shows the corresponding p-V- and T-s-diagrams. Since we consider open system devices for the realization of the cycle, the corresponding work and heat contributions are

Since the enthalpy of an ideal gas depends only on temperature, but not on pressure, the amounts of heat exchanged on the isobaric legs are equal in magnitude with opposite signs: a regenerator can be used for internal exchange of heat. In fact, the regenerator must be a counter-flow heat exchanger, which leads to the schematic shown in Fig. 13.6.

With the use of the regenerator, only the heat q34 must be supplied from the outside, and the thermal efficiency of the ideal cycle becomes

This, again, is the Carnot efficiency, that is the best possible efficiency obtain- able from a heat engine operating between reservoirs at temperatures TH , TL.

As the Stirling engine, the Ericsson engine uses external heat supply, which, in principle, allows the use of any heat source.

The Ericsson cycle relies on isothermal turbine and compressor, which require heat exchange during compression and expansion. Since heat transfer is slow, these are difficult to realize: Fast compressors and turbines normally are adiabatic, since the mass flows through too fast so that there is no time for significant heat transfer. Adiabatic compression with intercooling, and adiabatic expansion with reheat, together with regeneration, as discussed in the next sections, are means to bring gas turbine cycles closer to the Ericsson cycle, and thus improve their efficiency.