HUNTING

If the torque output of a prime mover pulsates, it may cause the rotor of the alternator to be pulled ahead of, and then behind, its normal running position. A diesel engine is one example of a prime mover that has a pulsating torque output. If an alternator is used with a diesel engine, the alternator rotor periodically will move slightly faster and then slower. This pulsating or oscillating effect is called hunting. It causes the current to surge back and forth between alternators operating in parallel. This condition is unsatisfactory and may become cumulative, resulting in such a large increase in the current between the alternators that the overload relays open the circuit.

Hunting can be corrected by the use of a heavy flywheel. A damper winding is often used in the rotating field structure to minimize the pulsating torque. Figure 12–2 showed a damper winding, which is often called an amortisseur winding. This winding is embedded in slots in each of the pole faces of the rotating field. The amortisseur winding consists of heavy conductors that are brazed or welded to two end rings. At the instant that hunting develops, the path of the armature flux changes so that it cuts the short-circuited conductors of the amortissuer winding. This change in the flux path produces induced currents in the damper winding. The currents oppose the force producing them (by Lenz’s law). The proper design of the damper winding ensures that the effects of hunting are canceled by the induced currents in the short-circuited conductors.

SUMMARY

• An emf is generated

1. when there is relative motion between the armature conductors and the field.

2. in armature conductors when rotating in a magnetic field with stationary field poles.

3. in stationary armature conductors when the field poles rotate past the conductors.

• A dc generator has stationary field poles and rotating armature conductors. The alternating voltage induced in the rotating armature conductors is changed to a direct voltage at the brushes by means of the commutator.

• AC generators (alternators) do not use commutators.

• Alternators are classified into two groups:

1. Revolving armature machines with stationary fields; the kilovolt-ampere capacity and the low-voltage rating of these machines are usually rather small.

2. Revolving field machines with stationary armature (stator) conductors.

a. The field poles rotate inside the stator.

b. Higher voltages can be generated without insulation failure.

c. Higher current values can be obtained without arcing or heat production at the brushes and slip rings.

• There are two types of revolving fields:

1. The salient field rotor (used with slow-speed alternators up to 1800 r/min).

2. The cylindrical field rotor (used for speeds from 1800 to 3600 r/min; most steam turbine-driven alternators have cylindrical rotors).

• An ac generator cannot supply its own field current:

1. The field excitation is direct current and is supplied from an external direct-current source.

2. Slip rings and brushes are used to take the excitation current from the external source to the field windings.

3. The field voltage is usually in the range between 100 and 250 V.

4. The amount of power delivered to the field circuit is relatively small.

• The induced field voltage is large enough to damage equipment. To eliminate this dan- ger, a special field discharge switch is used.

1. In the closed position, the field discharge switch acts like a normal double-pole, single-throw switch.

2. When the switch is opened, an auxiliary blade closes just before the main switch blades open.

3. When the main switch blades are fully open, a circuit path still exists through the auxiliary switch blade.

4. This path goes through the field discharge resistor, bypassing the field rheostat and the ammeter.

5. The voltage induced in the field coils by the collapsing magnetic field dissipates quickly as a current through the field discharge resistor.

6. A large machine may use a field contactor or field circuit breaker for the same purpose; each of these devices has two normally open main poles and one over- lapping normally closed discharge pole.

• Large three-phase, revolving field-type ac generators can use one of several types of stationary armature (stator) windings; these windings generally consist of an even number of coils spaced around the perimeter of the stator core.

1. The formed coil is machine wound and insulated before it is installed in the slots of the stator core.

2. A full-pitch coil spans the distance between poles of opposite polarity.

3. A fractional-pitch coil is smaller than the distance between poles of opposite polarity. All of the coils of one single-phase winding are known as a phase belt.

a. Connecting the formed coils of a phase belt (single-phase winding) in series yields a maximum voltage.

b. Reconnecting the same coils in parallel yields the maximum current possible at a lower voltage value.

4. A three-phase alternator has three separate windings that are placed in the slots of the stator core.

a. The windings are arranged so that three voltages are produced and are 120 electrical degrees apart.

b. The three single-phase windings (phase belts) may be connected in either delta or wye.

c. The wye connection is more commonly used because it gives a higher terminal voltage: 1.73 times the phase winding voltage.

• Eddy currents in the stator core due to the flux of the revolving field can be reduced by the use of a laminated core. Such a core consists of thin strips of steel clamped together.

• Ventilating ducts in the core of the stator and ventilating passages in the steel frame prevent the temperature of the stator windings from becoming too high.

1. When the alternator has a salient field rotor, it acts as a fan to aid cooling.

2. High-speed alternators with cylindrical rotors normally have a cooling system that completely encloses the alternator. Either air or hydrogen is used in the system. Hydrogen is more efficient than air because it has almost seven times the heat conductivity of air. However, hydrogen is explosive and is costly to replace.

• When an armature conductor of a generator is cut by a rotating magnetic field, the induced voltage is

• Controlling the field current:

1. The voltage induced in any alternator depends on the field strength and the speed of the rotor.

2. To maintain a fixed frequency, an alternator must operate at a constant speed.

3. The magnitude of the generated voltage depends on the dc field excitation.

4. The following method can be used to change or control the terminal voltage:

a. A rheostat is connected in series with the separately excited field circuit.

b. If an alternator is operated at a constant speed with a fixed field excitation cur- rent, the terminal voltage will change with an increase in the load current.

c. The actual change in voltage is influenced by the power factor of the load circuit and the impedance of the armature windings.

• Percent voltage regulation is the change in the terminal voltage from a full-load to a no-load condition at a constant speed and a fixed field excitation current:

• Vector diagrams can be used to determine the induced voltage of an alternator for different load power factors:

• At a lagging power factor, the induced voltage is greater than when the load power factor was unity.

• At a leading power factor, the induced voltage is less than when the load power factor was unity. In this case, the induced voltage is less than the terminal voltage.

• Synchronous reactance:

1. The voltage drop due to the inductive reactance and the armature reaction have the same effect on the terminal voltage.

2. Both of these effects are proportional to the armature current.

3. These two effects are known as the synchronous reactance, X .

The synchronous impedance test is used to determine values of R and XLS

1. In this test, the field excitation current and the alternator speed are kept at constant values.

2. The line terminals of the alternator are shorted through an ammeter when the test switch is closed.

3. The field excitation current increases until the current in the armature is nearly 150% of the rated full-load current. This value of current is recorded.

4. The test switch is opened and the reading of a voltmeter connected across the generator terminal is recorded.

5. The synchronous impedance is

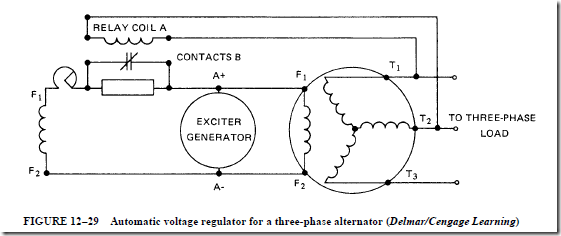

• A relatively constant alternator terminal voltage can be maintained under changing load conditions by the use of an automatic voltage regulator:

1. As the terminal voltage decreases, a relay closes contacts in the regulator to short out a field resistor. There is a resulting increase in the field current, field flux, and induced voltage.

2. An increase in the terminal voltage causes the relay to open the contacts across the field resistor. This action causes a decrease in the field current, field flux, and induced voltage.

3. Many other types of automatic voltage regulators may be used with alternators.

These regulators may use vacuum tubes, amplidynes, magnetic amplifiers, ignition rectifiers, controlled silicon rectifiers, or solid-state control devices.

• Saturation point:

1. For a constant-speed generator, the generated voltage is a direct function of the flux value per pole.

2. The flux is determined by the number of ampere-turns of the field pole. Because the number of turns on each field winding is constant, the flux is proportional to the dc excitation.

3. Increasing the dc excitation increases the flux; therefore, the induced voltage also increases.

4. A point is reached at which the flux no longer increases in proportion to the increase in dc excitation. This point is called the saturation point.

• Reading the saturation curve:

1. The saturation curve shows an increase in induced voltage with an increase in the field current in an alternator.

2. The ascending curve shows an increase in induced voltage as the field current is increased; the descending curve represents a decrease in induced voltage as the field current is decreased.

3. The first part of the ascending curve is nearly vertical because the induced voltage is almost directly proportional to the increase in field current.

4. When the alternator is being driven and the field current is zero, there is a small induced voltage. This voltage is due to the effects of residual magnetism after the magnetomotive force is removed from the field.

5. As the ascending curve reaches the saturation point, it flattens out. From this point to the maximum induced voltage on the curve, the increase in induced voltage is not proportional to the increase in field current.

6. The knee of the ascending curve is located immediately before and after the saturation point.

7. After reaching the maximum induced voltage, the field current is decreased to zero. The resulting plot of these events is the descending curve.

8. Note that the descending curve has a slightly higher induced voltage than does the ascending curve. This reaction is due to molecular friction or hysteresis effects in which the molecules of the iron in the magnetic circuit stay aligned even after the magnetomotive force is decreased.

9. The operating point of a particular generator occurs near the center of the knee of the ascending curve. At this point, there is a maximum ac voltage output with minimal I2 R losses in the field circuit.

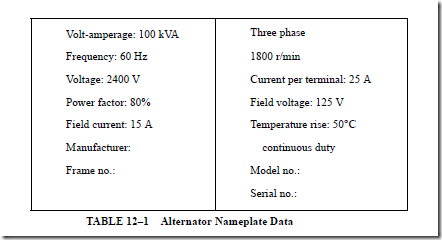

• The alternator nameplate contains the following data:

1. The capacity of the alternator, in kVA

2. The full-load terminal voltage

3. The rated full-load current per terminal

4. The number of phases

5. The frequency

6. The speed in r/min

7. The operating power factor

8. The dc field current and voltage

9. The maximum temperature rise

• Power losses in an alternator consist of fixed or stray losses such as

1. the bearing and brush friction losses.

2. windage losses.

3. iron losses, including eddy current and hysteresis losses.

4. copper losses, including the I2 R losses in the armature windings and the power expended in the separately excited field circuit.

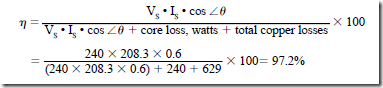

• Alternator efficiency:

2. An alternator should be operated at or near the rated full-load output to obtain the maximum efficiency.

3. Alternators with capacities in the order of 200,000 kVA may have efficiency ratings as high as 96% at the full-load output.

• Advantages of paralleling alternators:

1. They aid in scheduling of maintenance and emergency repairs on alternators.

2. They allow the alternators on the line to be operated near their full-load rating (high efficiency range). Another alternator may be paralleled with the first one to meet peak demands.

3. The generating plant capacity may be expanded to meet increased power demands by installing more alternators. These machines then operate in parallel with the existing generating equipment.

• To parallel ac generators:

1. Observe the following conditions:

a. The output voltages of the alternators must be equal.

b. The frequencies of the alternators must be the same.

c. The output voltages of the alternators must be in phase.

2. If these three conditions are met, the alternators are said to be in synchronism.

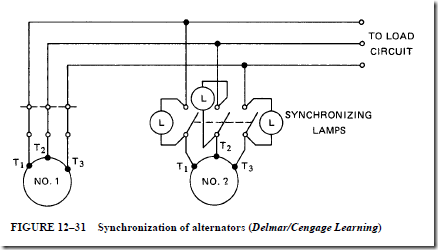

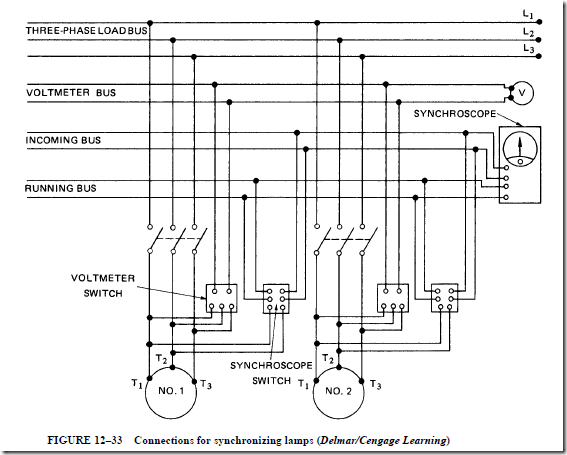

• Synchronizing two alternators:

1. Three-lamp method

a. The three lamps go on and off in unison depending on the frequency difference between the two alternators.

(1) For this case, a slight adjustment in the speed of the prime mover for the alternator coming on line will make the frequency of this machine the same as the alternator presently on the line.

(2) When all three lights go out, the instantaneous electrical polarity of the second machine will equal that of the alternator on the line. The second machine can be brought on line, and the generators will be paralleled.

b. The three lamps will light and go off, but not in unison. In this case, the phase sequence or phase rotation of the second generator is not the same as the alternator on the line. By interchanging the connections of any two leads of the second alternator, the phase sequence can be changed. The steps in part 1 can be followed to adjust the frequency of the second machine so that it can be paralleled.

2. Three lamps dark method

a. This method is used to determine the phase sequence of an alternator.

b. Once the phase sequence is known, permanent connections can be made between the stator windings, the switching equipment, and the station bus bars. It is not necessary to determine the phase sequence each time the alter- nator is paralleled once the equipment is marked correctly.

c. This method is also used to indicate when alternators are in synchronism.

3. Two bright, one dark method:

a. This method is never used to determine the phase sequence.

b. It is used to indicate the synchronism of two alternators.

c. When the incoming alternator is in synchronism (ready to be paralleled), two lamps in lines 1 and 2 will have a maximum brightness and the lamp in line 3 will be dark.

4. There are disadvantages to both methods of testing:

a. There may be a large voltage difference across the synchronizing lamps (even when they are dark); thus, a large voltage difference and phase difference may be present.

b. When an attempt is made to bring the incoming alternator into the bus bar circuit system with the other machines, a large disturbance in the electrical system may result in damage to the alternator windings.

• Use of the synchroscope:

1. Once the phase sequence is known to be correct and permanent connections are made, a synchroscope can be used.

2. The single-phase synchroscope indicates synchronism accurately.

3. A synchroscope gives an accurate indication of the differences in the frequency– phase relationship between two voltages.

a. A pointer rotates over a dial face. When the pointer stops, the frequencies of the two alternators are the same.

b. When the pointer stops in a vertical upward position, the frequencies are equal and the voltages are in phase. This means that the alternators are in syn- chronism and the alternator switch can be closed to parallel both machines.

• Once the two alternators are operating in parallel, the load is shared between them.

1. The load taken by each machine is proportional to the kVA rating of the machine.

2. Changing the field excitation of each dc generator will divide the load between the generators connected in parallel. The same method cannot be used to divide the kilowatt load between the two alternators in parallel.

3. A different method is used to divide the load between two alternators.

a. The prime movers for such alternators should have drooping speed–load characteristic curves.

b. To divide the load equally between the two machines, the input to the prime mover must be increased. The governor on the prime mover of the light-load alternator is opened slightly. As a result, there is an increase in both the horse- power of the light-load alternator and the power output of the alternator. At the same time, the governor on the prime mover of the heavy-load alternator is closed very slightly. This action causes decreases in the input to the prime mover, the horsepower input to the heavy-load alternator, and the power out- put (in kW) of the same alternator.

c. Careful adjustment of the governors of both prime movers can result in the speed–load characteristic curve of each cutting the system frequency line at the same load point. Thus, there is a satisfactory load division between the machines.

d. This adjustment of the prime movers must be obtained without causing a change in the frequency.

• When alternators are operating in parallel, a faulty governor may cause the speed of an alternator to increase; thus, the machine may be pulled out of synchronism.

1. Certain reactions within the alternator will prevent this condition.

2. If the governor malfunctions so that it cuts out completely and shuts off the input to the prime mover, the alternator will operate as a synchronous motor until the governor fault is corrected.

• Hunting

1. is a pulsating or oscillating effect.

2. of the prime mover causes a torque that may cause the rotor of the alternator to be pulled ahead of, and then behind, its normal running position.

3. causes the current to surge back and forth between alternators operating in parallel; this condition is unsatisfactory and may become cumulative, resulting in the circuit being opened by the overload relays.

4. can be corrected by using

a. a heavy flywheel.

b. a damper winding in the rotating field structure. Such a winding is often called an amortisseur winding. The proper design of this winding ensures that the effects of hunting are canceled by the induced currents in the short- circuited conductors.

Achievement Review

1. List two advantages of the rotating field alternator, as compared with the rotating armature ac generator.

|

2.

|

a.

b.

|

Where is the salient pole rotor used? Where is the cylindrical rotor used?

|

|

3.

|

a.

|

Explain why a field discharge resistor is used with the separately excited field circuit.

|

|

b.

|

Draw a schematic wiring diagram of a separately excited field circuit of an alternator. Include a field discharge switch, a field discharge resistor, an ammeter, and a field rheostat. Connect the circuit so that the field rheostat and the ammeter are not in the field discharge circuit path.

|

|

4.

|

a.

|

What methods are used to cool the windings of a high-speed turbine-driven alternator having a large kVA capacity?

|

|

b.

|

There are fewer problems in cooling the windings of slow-speed alternators using salient pole rotors. Why?

|

|

5.

|

A

|

25-kVA, 250-V, 60-Hz, 1800-r/min, single-phase alternator has an

|

armature resistance of 0.12 W and an armature reactance of 0.5 W. The generator delivers the rated load output at a power factor of 1.00 (unity) to a non- inductive load. Determine the induced voltage. (Neglect any armature reaction.)

6. a. Determine the induced voltage of the alternator in question 5 when it delivers the rated output to a load with a lagging power factor of 0.8660.

b. Determine the induced voltage of the alternator in question 5 when it delivers the rated output to a load with a leading power factor of 0.8660.

7. a. Define voltage regulation as it is used with alternators.

b. The full-load terminal voltage of an alternator is 240 V. The load is removed.

The no-load terminal voltage increases to 265 V at the same speed and field excitation. What is the percent voltage regulation of the alternator?

8. A three-phase, wye-connected alternator is rated at 2000 kVA, 4800 V, 60 Hz. In a short-circuit synchronous impedance test, the field excitation current is increased until the three line ammeters indicate nearly 150% of 360 A, the rated line cur- rent. The field excitation current and the speed are kept constant and the three-pole switch is opened. The voltmeter indicates 2250 V. The dc resistance between the line terminals is 0.4 W, and the ratio of effective to ohmic resistance is 1.5. Determine

a. the synchronous impedance.

b. the effective resistance.

c. the synchronous reactance.

9. Determine the no-load voltage and the percent voltage regulation for the alterna- tor in question 8. Assume that the alternator is delivering the rated current to a noninductive, unity power factor load.

10. a. Determine the no-load voltage and the percent voltage regulation for the alter- nator in question 8 assuming that it is delivering the rated current to a load with a lagging power factor of 0.8.

b. Find the no-load voltage and the percent voltage regulation for the same alter- nator when it delivers the rated current to a load with a leading power factor of 0.8.

11. Explain what is meant by the terms

a. synchronous reactance.

b. synchronous impedance.

12. a. Draw a typical saturation curve for an alternator.

b. Give two reasons why saturation curves are used.

13. a. What are the fixed losses of an alternator?

b. What are the copper losses of an alternator?

c. How is the full-load efficiency of an alternator determined?

14. A three-phase, wye-connected alternator is rated at 500 kVA, 2400 V, 60 Hz.

Determine

a. the full-load kilowatt output of the generator at 80% lagging power factor.

b. the full-load current per line terminal for the alternator.

c. the full current rating of each of the phase windings.

d. the voltage rating of each of the phase windings.

15. A three-phase, delta-connected, diesel-driven alternator is rated at 50 kVA, 240 V, 60 Hz.

a. Determine

(1) the full-load current rating per line terminal for the alternator.

(2) the full-load current rating of each of the phase windings.

(3) the voltage rating of each of the phase windings.

b. If the alternator has a rated speed of 240 r/min, how many poles are required for the rotating field?

16. A 5-kVA, 208-V, three-phase alternator is connected in wye.

a. Determine

(1) the line current per terminal at full load.

(2) the coil current at full load.

(3) the voltage of each phase winding.

b. Assuming that this alternator is reconnected in delta, compute the new terminal voltage and the current at full load.

17. A three-phase, 60-Hz, wye-connected turbine-driven alternator has three single- phase windings. Each winding is at 8000 V and 625 A. The alternator has four poles. Determine

a. the kilovolt-ampere rating of the alternator.

b. the kilowatt output of the alternator when it delivers the rated current to a load with an 80% lagging power factor.

c. the line voltage.

d. the rated full-load line current.

e. the speed in r/min of the revolving field of the alternator.

18. For the turbine-driven, high-speed alternator described in question 17, answer the following questions:

a. Why is the field, rather than the armature, the rotating member?

b. Why is a cylindrical rotating field used, rather than one with salient poles?

c. How is the dc excitation current supplied to the rotor of the rotating field alternator?

19. List three reasons why ac generators are operated in parallel.

20. A three-phase, wye-connected alternator is rated at 10,000 kVA, 11,000 V, and 60 Hz. Determine

a. the full-load kilowatt output of the ac generator at a lagging power factor of 80%.

b. the full-load line current of the alternator.

c. the voltage rating of each of the three windings.

d. the horsepower input to the alternator when it delivers the rated load output at an efficiency of 92% and a lagging power factor of 80%.

21. A 240-V, single-phase, 60-Hz, revolving field alternator delivers 30 kW to a non- inductive load. The generator efficiency is 86%, and the stray power losses are 2000 W. The separately excited field requires 6 A at 240 V, dc. Determine

a. the full-load current.

b. the copper losses in the stator winding.

22. a. List the steps, in chronological order, required to place a three-phase alterna- tor in parallel with another ac generator. Assume that this is the first time that the alternator is placed in service.

b. After paralleling the alternators, what means are used to redistribute the kilo- watt load between the two alternators? Assume that the frequency is held constant.

23. a. Diagram the “three lamps dark” method of synchronizing an alternator to the bus bars.

b. How is this method used to determine whether the phase sequence of an alternator is correct with reference to the station bus bars?

24. a. Diagram the “two lamps bright, one lamp dark” method.

b. How is this method used to determine when an incoming alternator is in phase with the bus bars?

25. a. What does the term hunting mean as applied to slow-speed alternators?

b. How does the amortisseur or damping winding on the field rotor decrease the effects of hunting?

c. What other way is used to minimize the effects of hunting?

26. Explain how equal load distribution is obtained between alternators in parallel.

27. Explain what happens when an attempt is made to shift the kilowatt load between alternators by changing the field excitation. Assume that the input to the prime movers of the alternators is not changed.

List the data commonly found on the nameplate of an alternator.

![image_thumb[1] image_thumb[1]](http://lh6.ggpht.com/-AMQJhh2dICk/VLLIAI1X5qI/AAAAAAABEX0/90KAvLPbm0Q/image_thumb1_thumb.png?imgmax=800)

![image_thumb[2] image_thumb[2]](http://lh4.ggpht.com/-Za0tUvvZJ_g/VLLIDDjl1fI/AAAAAAABEYE/P-sU_3pZM6Q/image_thumb2_thumb.png?imgmax=800)

![image_thumb[3] image_thumb[3]](http://lh6.ggpht.com/-Ad9gztLcXQY/VLLIGkP9m6I/AAAAAAABEYU/7w4gBuQHa2g/image_thumb3_thumb.png?imgmax=800)

![image_thumb[4] image_thumb[4]](http://lh6.ggpht.com/-0Go9wnPKMeg/VLLIKsrJaqI/AAAAAAABEYk/zDBJKuyVzdE/image_thumb4_thumb.png?imgmax=800)

![image_thumb[5] image_thumb[5]](http://lh6.ggpht.com/-udcoqtODedM/VLLIOR96nRI/AAAAAAABEY0/0fD0Cb4PpK8/image_thumb5_thumb.png?imgmax=800)