BUS DUCTS AND PANEL PROBLEMS

Triplen harmonic currents can also cause problems with neutral bus ducts and connecting lugs. A neutral bus is sized to carry the rated phase current. Because triplen harmonics can cause the neutral current to be higher than the phase current, it is possible for the neutral bus to become overloaded.

Electrical panels and bus ducts are designed to carry currents that operate at 60 Hz. Harmonic currents produce magnetic fields that operate at higher frequencies. If these fields should become mechanically resonant with the panel or bus duct enclosures, the panels and bus ducts can vibrate and produce buzzing sounds at the harmonic frequency.

Telecommunications equipment is often affected by harmonic currents. Tele- communication cable is often run close to power lines. To minimize interference, communication cables are run as far from phase conductors as possible and as close to the neutral conductor as possible. Harmonic currents in the neutral conductor induce high- frequency currents into the communication cable. These high-frequency currents can be heard as a high-pitched buzzing sound on telephone lines.

Determining Harmonic Problems on Single-Phase Systems

There are several steps that can be followed in determining whether there is a problem with harmonics. One step is to do a survey of the equipment. This is especially important in determining whether there is a problem with harmonics in a single-phase system.

1. Make an equipment check. Equipment such as personal computers, printers, and fluorescent lights with electronic ballast are known to produce harmonics. Any piece of equipment that draws current in pulses can produce harmonics.

2. Review maintenance records to see whether there have been problems with circuit breakers tripping for no apparent reason.

3. Check transformers for overheating. If the cooling vents are unobstructed and the transformer is operating excessively hot, harmonics could be the problem. Check transformer currents with an ammeter capable of indicating a true RMS current value. Make sure that the voltage and current ratings of the transformer have not been exceeded.

It is necessary to use an ammeter that responds to true RMS current when making this check. Some ammeters respond to the average value, not the RMS value. Meters that respond to the true RMS value generally state this on the meter. Meters that respond to the average value are generally less expensive and do not state that they are RMS meters.

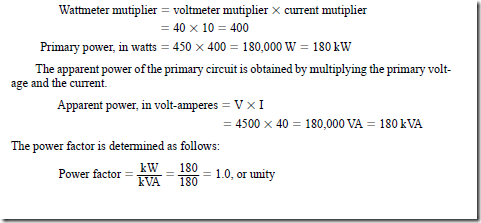

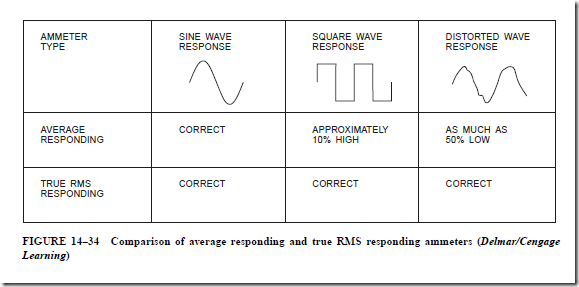

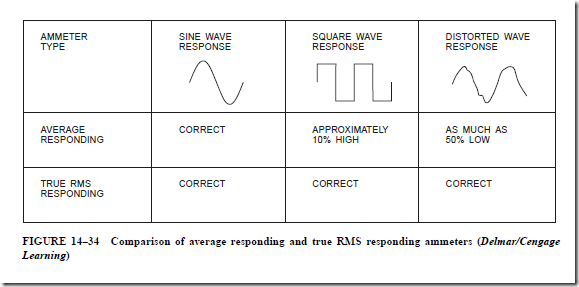

Meters that respond to the average value use a rectifier to convert the alternating current into direct current. This value must be increased by a factor of 1.111 to change the average reading into the RMS value for a sine-wave current. True RMS responding meters calculate the heating effect of the current. The chart in Figure 14–34 shows some of the differences between average indicating meters and true RMS meters. In a distorted waveform, the true RMS value of current will no longer be average × 1.111 (Figure 14–35). The distorted wave- form generally causes the average value to be as much as 50% less than the RMS value.

value of 36.8 A, and the average ammeter indicates a value of 24.8 A. Determine the ratio of the two measurements by dividing the average value by the true RMS value:

A ratio of 1 would indicate no harmonic distortion. A ratio of 0.5 would indicate extreme harmonic distortion. This method does not reveal the name or sequence of the harmonic distortion, but it does indicate whether there is a problem with harmonics.

The most accurate method for determining whether there is a harmonics problem is to use a harmonic analyzer. The harmonic analyzer will determine the name, sequence, and amount of harmonic distortion present in the system.

Determining Harmonic Problems on Three-Phase Systems

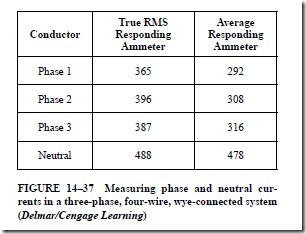

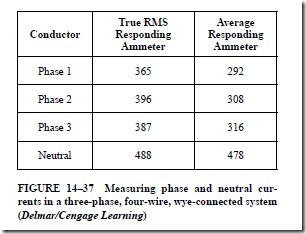

Determining whether a problem with harmonics exists in a three-phase system is similar to determining the problem in a single-phase system. Because harmonic problems in a three-phase system generally occur in a wye-connected, four-wire system, this example will assume a delta-connected primary and wye-connected secondary with a center-tapped neutral as shown in Figure 14–32. To test for harmonic distortion in a three- phase, four-wire system, measure all phase currents and the neutral current with both a true RMS indicating ammeter and an average indicating ammeter. It will be assumed that the three-phase system being tested is supplied by a 200-kVA transformer, and the current values shown in Figure 14–37 were recorded. The current values indicate that a problem with harmonics does exist in the system. Note the higher current measurements made with the true RMS indicating ammeter, and also the fact that the neutral current is higher than any phase current.

Dealing with Harmonic Problems

After it has been determined that harmonic problems exist, something must be done to deal with them. It is generally not practical to remove the equipment causing the harmonic distortion, so other methods must be employed. It is a good idea to consult a power quality expert to determine the exact nature and amount of harmonic distortion present. Some general procedures for dealing with harmonics follow:

1. In a three-phase, four-wire system, the 60-Hz part of the neutral current can be reduced by balancing the current on the phase conductors. If all phases have equal current flow, the neutral current would be zero.

2. If triplen harmonics are present on the neutral conductor, harmonic filters can be added at the load. These filters can help reduce the amount of harmonics on the line.

3. Pull extra neutral conductors. The ideal situation would be to use a separate neutral for each phase, instead of using a shared neutral.

4. Install a larger neutral conductor. If it is impractical to supply a separate neutral conductor for each phase, increase the size of the common neutral.

5. Derate or reduce the amount of load on the transformer. Harmonic problems generally involve overheating of the transformer. In many instances it is necessary to derate the transformer to a point that it can handle the extra current caused by the harmonic distortion. When this is done, it is generally necessary to add a second transformer and divide the load between the two.

Determining Transformer Harmonic Derating Factor

Probably the most practical and straightforward method for determining the derating factor for a transformer is recommended by the Computer & Business Equipment Manufacturers Association. To use this method, two ampere measurements must be made. One is the true RMS current of the phases and the second is the instantaneous peak phase current. The instantaneous peak current can be determined with an oscilloscope connected to a cur- rent probe or with an ammeter capable of measuring the peak value. Many of the digital clamp-on ammeters are capable of measuring the average, true RMS, and peak values of current. For this example, it will be assumed that peak current values are measured for the 200-kVA transformer discussed previously. These values are added to the previous data obtained with the true RMS and average indicating ammeters (Figure 14–38). The formula for determining the transformer harmonic derating factor (THDF) is

This formula will produce a derating factor somewhere between 0 and 1.0. Because the instantaneous peak value of current is equal to the RMS value × 1.414, if the current wave- forms are sinusoidal (no harmonic distortion), the formula will produce a derating factor of 1.0. Once the derating factor is determined, multiply the derating factor by the kVA capacity of the transformer. The product will be the maximum load that should be placed on the transformer.

SUMMARY

• Most electrical energy is generated by three-phase alternating-current generators.

1. Three-phase systems are used to transmit and distribute this electrical energy.

2. For economy, the generated three-phase voltage is stepped up to an extremely high voltage by three-phase transformers for long-distance transmission over the three-phase system.

3. Three-phase transformers are used at distribution points to step down the high voltage to a safe and usable level.

• A large three-phase transformer is completely enclosed in one container. Three single- phase transformers, connected in a bank, can be used to transform the voltages of three- phase systems at distribution points.

1. These transformers may be connected in any one of four standard ways:

a. Delta–delta

b. Wye–wye

c. Delta–wye

d. Wye–delta

2. Another method is the open-delta (or V) connection. This connection uses only two single-phase transformers to transform the voltages on a three-phase system.

• The delta–delta connection:

1. The delta–delta connection is used to supply an industrial load by stepping down a 2400-V, three-phase, three-wire service to a 240-V, three-phase, three-wire service.

2. For most applications, the load is balanced and the three single-phase transformers have the same kilovolt-ampere rating.

3. The primary and the secondary windings are connected in delta.

4. To determine the total capacity in kilovolt-amperes of a delta–delta-connected transformer bank, the three kVA ratings are added.

• For any delta-connected circuits and systems:

1. Each transformer winding is connected across the two line leads; thus, the line voltage and the transformer coil winding voltage are the same.

2. The line current is equal to M3 or 1.73 times the coil winding current.

3. In a closed-delta transformer connection, each line wire is fed by two trans- former coil currents that are out of phase. These coil currents do not add directly, but must be added vectorially to obtain the line current.

• Feeding a dual load using a delta–delta connection—some power companies use a delta–delta-connected transformer bank to feed two types of loads:

1. A 240-V, three-phase industrial load.

2. A 120/240-V, single-phase, three-wire lighting load.

a. The transformer supplying the lighting load is larger than the other two trans- formers of the three-phase system.

b. The neutral wire is tied to the midpoint of the 240-V, low-voltage secondary winding.

c. Many transformers have two 120-V windings. These windings are connected in series and the neutral is brought out at the midpoint to give a 120/240-V service.

3. Both lines A and C have 120 V to the grounded neutral. Line B has approximately 208 V to ground. This connection can be a serious hazard and cannot be used for lighting service.

• Procedure for making a closed-delta connection:

1. Two primary winding leads are brought out of the transformer and are marked H1 and H2. It is assumed that H1 is the beginning and H2 is the ending of each high-voltage winding. The H2 end of each primary winding is connected to the beginning (H1) of the next primary winding to form a series arrangement.

2. One three-phase primary source line is connected to each junction of two windings. With a 2400-V source, each of the primary windings has a line voltage of 2400 V impressed across it.

3. Once the high-voltage primary connections are made, the three-phase, 2400-V input may be energized and tested for the correct phase rotation. If the phase rotation is incorrect, the circuit is deenergized and any two line wires are interchanged.

4. To determine whether a transformer has additive or subtractive polarity, the terminal markings or the nameplate data can be checked.

5. The secondary closed-delta connection is the same as the primary connection, with X1 substituted for H1 and X2 substituted for H2. The primary side of the delta-connected transformer may be connected so as to cause a polarity reversal in one of its legs. A phase inversion on the primary side must be corrected on the secondary side.

a. Determine whether the voltage output of each of the three transformers is the same as the voltage rating on the nameplate.

b. Connect the end of one secondary winding to the beginning of another secondary winding. If the connection is correct, the voltage across the open ends of the two transformers should be the same as the output of each transformer. If the connections are not correct, the resultant voltage is M3 times the secondary rated voltage. The phase reversal is corrected by interchanging the connections to one of the coils.

c. With the correct voltage on the two coils, add the end of the third secondary winding coil to the beginning of the second coil. The resultant voltage is opposite to each secondary voltage and has a magnitude equal to the secondary voltage. If the voltage is zero across the last pair of open leads, they can be connected together. A line wire is attached at each of the connection points. These three line wires form the three-phase output. If the voltage reading is not zero, reverse the connections of the last transformer coil before the delta connection is closed and the output lines are added.

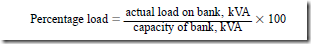

• The percentage load on a transformer bank connected in closed delta, in terms of its rated capacity, is

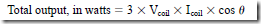

• The total output of a closed-delta connection is

• The total output of a closed-delta connection is

• The wye–wye connection:

1. This connection can be used when the load on the secondary side is balanced. If the secondary load consists of three-phase motors only and the load currents are balanced, the wye–wye connection can be used.

2. This connection cannot be used if the secondary load becomes unbalanced. An unbalanced load causes a serious imbalance in the three voltages of the trans- former bank.

3. A fourth wire, known as the neutral wire, is added to eliminate unbalanced volt- ages. It is connected between the source and the common point on the primary side of the transformer bank.

a. Each high-voltage winding is connected between the neutral and one of the three line leads. If the source is 2400/4160 V, the voltage across each high-voltage winding is 2400 V. The voltage across the three line leads is M3 X 2400, or 4160 V.

b. The neutral wire maintains a constant voltage across each of the high-volt- age windings, even when the load is unbalanced.

c. The neutral wire is grounded and helps protect the three high-voltage windings from lightning surges.

4. With the secondary connected in wye, each low-voltage winding is connected between the secondary neutral and one of the three line leads.

a. For a four-wire, three-phase system rated at 2400/4160 V and 120/280 V, the voltage output of each secondary winding is 120 V. There are 120 V between the neutral wire and any one of the three secondary line leads.

b. The voltage across the line wires is M3 X 120, or 208 V.

(1) 208-V, three-phase service is available for industrial power loads such as three-phase motors.

(2) 120 V is available for lighting loads.

5. Nearly all wye–wye-connected transformers use three single-phase transformers having the same kVA capacity:

6. In a wye–wye connection, a defective transformer must be replaced before the bank can be reenergized.

• The delta–wye connection:

1. This connection is also used for transformation to step up or step down a voltage.

2. The primary windings are connected in delta and the secondary windings are connected in wye.

3. This connection is used at a generator station to step up the voltage. The input voltage is stepped up by the transformer ratio. This voltage is further increased by M3, or 1.73 times the secondary coil voltage. The high voltage is then connected directly to three-phase transmission lines.

4. The insulation requirements are reduced for the secondary windings because the coil voltage is only 58% of the line voltage. (This fact is very important when the secondary side has a very high voltage.)

5. This connection can also be used at the distribution point to step down the voltage.

6. The delta–wye connection can be used for a three-phase, four-wire system for power and lighting.

a. In a 208/120-V system, 208 V supplies the three-phase power load and 120 V supplies the lighting load.

b. In a 480/277-V system, 480 V supplies the three-phase power load and 277 V supplies the lighting load.

(1) Standard 120-V fluorescent lighting fixtures are used with special ballasts for operation on 277-V circuits.

(2) A 277/480-V, three-phase, four-wire system has the following advantages:

(a) The I2 R drop is reduced in feeders and branch circuits, resulting in an increase in the operating efficiency.

(b) Smaller sizes of copper conductors, conduits, and equipment can be used to save up to 25% of the installation cost.

(c) The load demands on the 277/480-V system can be increased with a minimum of changes and expense.

c. In a building using a 277/480-V, three-phase system, the additional require- ment of a 120-V service uses little power. A transformer is added to step down the voltage from 480 V to 120/240 V. A small air-cooled transformer can be used to supply the 120-V service and is centrally located.

• The wye–delta connection:

1. This connection is used to step down relatively high transmission line voltages at the load center. A transformer bank of this type is commonly used to step down voltages of 60,000 V or more.

2. Advantages of the delta–wye connection are

a. the three-phase voltage is reduced by the transformer ratio times 1.73.

b. the insulation requirements are reduced for the high-voltage windings because the wye primary coil voltage is only 58% of the primary line voltage.

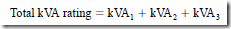

• For the delta–wye and wye–delta connections, the three single-phase transformers generally have the same kVA capacity, and the total capacity of the transformer bank, in kVA, is obtained by adding the kVA ratings of the three transformers.

• The open-delta connection (V connection):

1. This connection uses two transformers only.

2. It can be used in emergency situations when one of three transformers is damaged in a three-phase service. The damaged transformer is cut out of the system, and the configuration of the open-delta connection is used.

3. With two transformers supplying the service, the total capacity is only 58% of the capacity of the closed-delta connection.

4. On the secondary side, the line voltage and the line current are the same as the secondary coil current and voltage.

5. The original transformer installation may consist of an open-delta bank. As the industrial power load requirements increase, a third transformer may be added. When the third transformer is added, a delta–delta bank (closed-delta bank) is formed.

6. The total kVA capacity for an open-delta bank is Total kVA = kVA1 + kVA2 X 0.866

• Advantages of an enclosed three-phase transformer:

1. The operating efficiency of a three-phase transformer is slightly higher than the overall efficiency of three separate single-phase transformers.

2. The three-phase transformer weighs less and requires less space than do three separate single-phase transformers.

3. The three-phase transformer supplies the same kVA output and costs less than three single-phase transformers.

4. The installation equipment required (such as bus bars, switchgear, and wiring) is easier to install and is less complex than that required by a transformer bank consisting of three single-phase transformers.

• If the three-phase transformer develops a problem, such as a defective phase winding, then the entire three-phase unit must be taken out of service.

• T-connected transformers are similar to an open-delta connection in that only two trans- formers are required to make the connection.

1. Before two transformers can be connected T, one transformer must have a 50% tap on both the primary and secondary windings. It is preferable for the second transformer to have an 86.6% tap.

2. T-connected transformers are generally wound specially for the purpose and are contained in the same case.

3. The phase balance of the T-connected transformer is better than that of an open- delta bank.

4. The T-connected transformer can be connected to supply three-phase, four-wire service in a manner similar to that for a four-wire wye connection.

• Scott-connected transformers are similar to T-connected ones in that the main trans- former must have a 50% tap on both the primary and secondary, and the teaser trans- former must have an 86.6% tap.

1. The Scott connection is used to produce two-phase power from a three-phase connection.

2. A two-phase system has voltages 90° out of phase with each other.

• The zigzag connection is generally used for grounding purposes.

• Harmonics can cause heating problems in ac circuits.

• Harmonics are generally caused by devices that cause pulsations on the line such as switching power supplies and variable-frequency drives.

• The third harmonic generally causes overload conditions on neutral conductors.

• It is sometimes necessary to derate transformers because of harmonic problems.

Achievement Review

1. An industrial plant has a 2400-V, three-phase, three-wire service. It uses three 100-kVA, single-phase transformers. Each transformer is rated at 2400/240 V. The transformers supply a 240-V, three-phase, three-wire system. Each trans- former has additive polarity.

a. Draw a connection diagram showing how the transformer bank is connected.

Mark the polarity of all transformer leads.

b. A balanced load of 200 kW at a lagging power factor of 0.70 is supplied by the transformer bank. Determine

1. the secondary line current.

2. the secondary coil current.

3. the primary coil current.

4. the primary line current.

2. What is the percentage of load in kVA on the transformer bank described in question 1?

3. Explain a procedure that may be used to connect the secondary windings of single-phase transformers in closed delta.

4. a. Assume that one of the transformers in the delta–delta transformer bank in question 1 is cut out of service because it is damaged by lightning. Assuming that plant operations are cut to a minimum so that the peak load does not exceed the capacity of the two remaining transformers, show how they could be connected during this emergency.

b. What is the maximum balanced load, in kilowatts, at a lagging power factor of 0.70, that may be connected to the transformer bank during the emergency described in part a of this question?

5. Explain a procedure that may be used to connect the secondary windings of three single-phase transformers in wye.

6. Three single-phase, 20-kVA, 2400/120-V transformers are connected in a three- phase transformer bank. The transformers have additive polarity. The bank steps down the 2400/4160-V, three-phase, four-wire primary service to a 120/208-V, three-phase, four-wire secondary service. This service supplies both a 120-V, single-phase lighting load and a 208-V, three-phase motor load. Draw a schematic diagram of the connections for this transformer bank.

7. a. What is the maximum balanced three-phase load, in kVA, that can be connected to the transformer bank in question 6?

b. If the load has a lagging power factor of 0.80, what is the maximum output in kW that can be obtained from the transformer bank?

8. Give two practical applications for a delta–wye transformer bank. Give one practical application for a wye–delta transformer bank.

9. A three-phase, four-wire, wye-connected transmission system has a voltage of approximately 60,550 V across the three line wires. In addition, there is 35,000 V from each line wire to the neutral. This voltage is to be stepped down at a substation to supply energy to a 5000-V, three-phase, three-wire distribution sys- tem. Each transformer is rated at 35,000/5000 V, 2000 kVA. Each transformer has subtractive polarity. Draw a schematic wiring diagram for this circuit and determine

a. the full-load capacity of the bank, in kVA.

b. the line current on the secondary side when the transformer bank is loaded to its rated capacity.

c. the line current on the primary side when the transformer bank is loaded to its rated capacity, neglecting any losses.

10. What are typical applications of a 277/480-V, three-phase, four-wire, wye- connected system? What are the advantages of such a system?

11. a. List several advantages of a three-phase transformer, as compared with a three-phase bank consisting of three single-phase transformers.

b. Give one disadvantage of the use of a three-phase transformer.

12. The high-voltage windings of a three-phase transformer are connected in wye. The low-voltage windings are connected in delta. The actual ratio between the high- voltage windings and their respective low-voltage windings is 10:1. The primary side of the transformer is supplied from a three-phase, four-wire, 2400/4160-V circuit. The secondary output is a three-phase, three-wire service for a three-phase industrial motor load. Determine

a. the secondary voltage.

b. the kVA output of the bank, when the current supplied to the motor load on the secondary is 60 A in each line wire.

c. the line current in each line wire on the high-voltage primary side of the trans- former, neglecting any losses.

13. What is the frequency of the second harmonic?

14. Of the following, identify those that are considered triplen harmonics: third, sixth, ninth, twelfth, fifteenth, and eighteenth.

15. Would a positive rotating harmonic or a negative rotating harmonic be more harmful to an induction motor? Explain your answer.

16. What instrument should be used to determine what harmonics are present in a power system?

17. A 22.5-kVA single-phase transformer is tested with a true RMS ammeter and an ammeter that indicates the peak value. The true RMS reading is 94 A. The peak reading is 204 A. Should this transformer be derated, and if so, by how much?

PRACTICE PROBLEMS FOR UNIT 14

In the following problems, three single-phase control transformers have been con- nected to operate with a primary voltage of 240 V and a secondary voltage of 120 V. This gives each transformer a turns ratio of 2:1. It will be assumed that a line-to-line voltage of 208 V is connected to the primary winding, and that the load connected to the secondary has an impedance of 4 !1 in each phase. Find the unknown values in each of the following problems. It will be necessary to use the formulas in the Transformers and Three-Phase Connections sections of Appendix 15.

[Note: When computing values of voltage and current between the primary and secondary windings, use phase values and not line values.] In the following problems: