solid-state relay

A solid-state relay is less-commonly referred to by its acronym, SSR. It is sometimes regarded as an optocoupler, but in this encyclopedia the two components have separate entries. An optocoupler is a relatively simple device consisting of a light source (usually an LED) and a light sensor, in one package. It is used primarily for isolation rather than to switch a high current. A solid-state relay can be thought of as a substitute for an electromagnetic relay, usually has additional components in its package, and is intended to switch currents of at least 1A.

A component that works like a solid-state relay but only switches a 5V (or lower) logic signal may be referred to as a switch, even though it is entirely solid-state. This type of component is included in this entry because it functions so similarly to a solid-state relay.

What It Does

A solid-state relay (SSR) is a semiconductor package that emulates an electromagnetic re– lay (see Volume 1). It switches power on or off between its output terminals in response to a smaller current and voltage between its input terminals. Variants can switch AC or DC and may be controlled by AC or DC. An SSR functions as a SPST switch, and is available in normally open or normally closed versions. SSRs that function as an SPDT switch are relatively unusual and actual- ly contain more than one SSR.

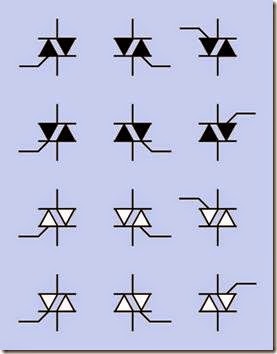

No single schematic symbol has been adopted to represent a solid-state relay, but some alter- natives are shown in Figure 4-1:

An unusually detailed depiction of an SSR that switches DC current using MOSFETS. Symbols for this device often omit the diodes

on the output side and may simplify the MOSFET symbols.

Bottom left

An SSR that uses an internal triac to switch

AC. The box labeled 0x indicates that this is a zero-crossing relay, meaning that it switches when alternating voltage crosses the 0V level from positive to negative or neg- ative to positive.

Bottom right

A generic SSR, showing a symbol for a nor- mally open relay, although whether it is de- signed for AC or DC is unclear.

Advantages

• Great reliability and long life.

• No physical contacts that are vulnerable to arcing and erosion or (under extreme con- ditions) that could weld themselves together.

• Very fast response, typically 1µs on and 0.5µs off.

• Very low power consumption on the input side, as low as 5mA at 5VDC. Many solid-state relays can be driven directly from logic chips.

• Lack of mechanical noise.

• No contact bounce; a clean output signal.

• No coil that would introduce back EMF into the circuit.

• Safe with flammable vapors, as there is no sparking of contacts.

• Often smaller than a comparable electro- magnetic relay.

• Insensitive to vibration.

• Safer for switching high voltages, as there is complete internal separation between input and output.

• Some variants work with input control vol- tages as low as 1.5VDC. Electromagnetic re- lays typically require at least 3VDC (or more, where larger relays are required to switch higher currents).

Disadvantages

• Less efficient; its internal impedance intro- duces a fixed-value voltage drop on the out- put side (although this may be negligible when switching higher voltages).

• Generates waste heat in its “on” mode, in ac- cordance with the voltage drop.

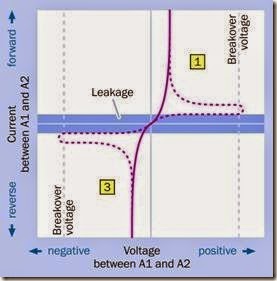

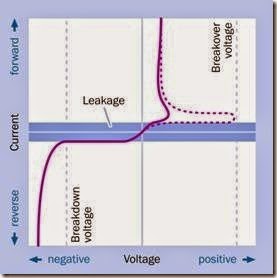

• Passes some leakage current (usually meas- ured in microamps) on the output side when the relay is supposed to be “off.”

• A DC solid-state relay usually requires obser- vation of polarity on the output side. An electromagnetic relay does not.

• Brief voltage spikes on the input side, which would be ignored by a slower electromag- netic relay, may trigger a solid-state relay.

• More vulnerable than an electromagnetic relay to surges and spikes in the current that is switched on the output side.

Figure 4-1. Schematic symbols for solid-state relays have not been standardized. See text for details.

How It Works

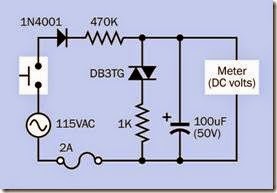

Almost all modern SSRs contain an internal LED (light-emitting diode, see Chapter 22) which is switched on by the control input. Infrared light from the LED is detected by a sensor consisting of one or more phototransistors or photodiodes. In a relay that controls DC current, the sensor usually switches a MOSFET (see Volume 1) or an SCR (silicon-controlled rectifier—see Chapter 1). In relays that control AC current, a triac (see Chapter 3) controls the output. Because the input side and the output side of the SSR are linked only by a light signal, they are electrically isolated from each other.

The MOSFETs require so little power, it can be provided entirely by light falling on an array of 20 or more photodiodes inside the SSR package.

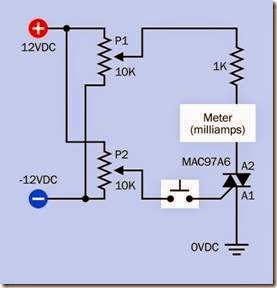

Typical solid-state relays are shown in Figures 4-2 and 4-3.

Figure 4-2. A solid-state relay capable of switching up to 7A DC. See text for a detailed description.

The Crydom DC60S7 accepts a control voltage ranging from 3.5VDC to 32VDC, with a typical in- put current of less than 3mA. Maximum turn-on time is 0.1ms and maximum turn-off time is 0.3ms. This relay can switch up to 7A and tolerates a surge of up to twice that current. It imposes a voltage drop of as much as 1.7VDC, which can become a drawback when switching voltages that are significantly lower than its maximum 60VDC. The electronics are sealed in thermally conductive epoxy, mounted on a metal plate ap- proximately 1/8” thick which can be screwed down onto an additional heat sink.

The Crydom CMX60D10 tolerates a more limited range of control voltages (3VDC to 10VDC) and requires a higher input current of 15mA at 5VDC. However, its very low maximum on-state resistance of 0.018Ω imposes a much smaller voltage drop of less than 0.2 volts when passing 10A. This results in less waste heat and enables a single- inline package (SIP) without a heat sink. The

CMX60D10 weighs 0.4 ounces, as opposed to the 3 ounces of the DC60S7. Relays from other manufacturers use similar packaging and have similar specifications.

Figure 4-3. A solid-state relay capable of switching up to 10A. Its lower internal resistance results in less waste heat and enables a smaller package. See text for a detailed description.

Variants

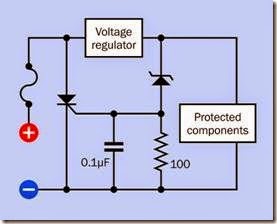

Many solid-state relays have protective components built into the package, such as a varistor on the output side to absorb transients. Check datasheets carefully to determine how much protection from external components may be necessary when switching an inductive load.

Instantaneous versus Zero Crossing

A zero crossing SSR is one that (a) switches AC current and (b) will not switch “on” until the instant when the AC voltage crosses through 0V. The advantages of this type are that it does not have to be built to switch such a high current, and creates minimal voltage spike when the switching occurs.

All SSRs that are designed to switch AC will wait for the next voltage zero crossing before switching to their “off” state.

NC and NO Modes

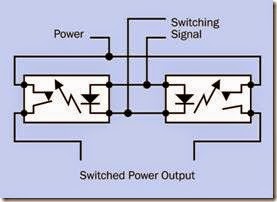

Solid-state relays are SPST devices, but different models may have a normally closed or normally open output. If you require double-throw operation, two relays can be combined, one normally closed, the other normally open. See Figure 4-4. A few manufacturers combine a normally closed relay and a normally open relay in one package, to emulate a SPDT relay.

Figure 4-4. A normally closed solid-state relay can be paired with a normally open solid-state relay to emulate a SPDT switch. This combination is available in a single package from some manufacturers.

Packaging

High-current solid-state relays are often pack- aged with screw terminals and a metal base that is appropriate for mating with a heat sink. Some are sold with heat sinks integrated. Spade terminals and crimp terminals may be optional. The Crydom DC60S7 shown in Figure 4-2 is an example. This type of package may be referred to as industrial mount.

Lower-current solid-state relays (5A or less), and those with a very low output resistance, may be packaged with single-inline pins for through- hole mounting in circuit boards.

Solid-State Analog Switch

DIP packaging may be used for solid-state relays that are designed for compatibility with the low voltages and currents of logic chips. This type of component may be referred to simply as a switch. The 74HC4316 is an example, pictured in Figure 4-5.

Figure 4-5. This DIP package contains four “switches” that function as solid-state relays but are restricted to low voltages and currents, compatible with logic chips. See text for details.

Typically the control voltage and the switched voltage are limited between +7V and −7V, with a maximum output current of 25mA. Each internal switch has its own Control pin, while an additional Enable pin forces all switches into an “off” state if its logic state is high. The simplified functionality of this component is illustrated in Figure 4-6, without showing internal optical isolation.

The “on” resistance of each internal pathway will be approximately 200Ω when the component is powered with +5VDC on the positive side and 0VDC on the negative side. This resistance drops to 100Ω if the negative power supply is -5VDC.

If all of the outputs from the chip are shorted together, it functions as a multiplexer (see Chap- ter 16). In fact, this type of switch component is often listed in catalogs as a multiplexer, even though it has other applications.

Because the component tolerates equal and opposite input voltages, it is capable of switching AC.

Figure 4-6. The functionality of a chip containing four solid-state analog switches. A high state on a Control pin closes its associated switch. The Enable pin must be held low for normal operation; a high Enable state forces all the switches into the “off” position. If the outputs are tied together, this component can function as a multiplexer.

Values

Industrial-mount solid-state relays typically can switch currents ranging from 5A to 500A, with 50A being very common. The higher-current re- lays mostly require DC control voltage; 4V to 32V are typical, although some versions can go much higher. They contain an SCR or triac to switch AC.

Smaller solid-state relays in SIP, DIP, or surface- mount packages often use MOSFETs on the out- put side, and are often capable of switching up to 2A or 3A. Some can switch either AC or DC, depending on the way the output is wired. The LED on the input side may require as little as 3mA to 5mA for triggering.

How to Use It

Solid-state relays find their primary uses in telecommunications equipment, industrial control systems and signalling, and security systems.

The component is very simple externally. Power on the input side can come from any source capable of delivering the voltage and current specified by the manufacturer, and any device that doesn’t exceed maximum current rating can be connected to the output side, so long as provision is made for suppressing back-EMF from an inductive load, as shown in Figure 4-7. Often a solid-state relay can be substituted directly for an electromagnetic relay, without modifying the circuit.

Figure 4-7. Use of a diode around an inductive load, to protect a solid-state relay from back-EMF.

Solid-state relays are heat sensitive, and their rating for switching current will diminish as their temperature increases. Manufacturer datasheets will provide specific guidance. Using a heat sink will greatly improve the performance. Bear in mind that the relay generates heat continuously while it is in its “on” mode—about 1 watt per ampere.

Because it requires so little current on the input side (typically no more than 15mA), a solid-state relay can usually be driven directly by chips such as microcontrollers that would not be able to ac- tivate an equivalent electromagnetic relay.

Applications may take advantage of the solid- state relay’s reliability, immunity to vibration, lack of contact sparking, freedom from coil- induced surges on the input side, and lack of contact bounce on the output side. A solid-state relay is ideal within digital equipment that is sensitive to power spikes. It may switch a fuel pump that handles volatile, flammable liquids, or a wastewater pump in a basement subject to flooding (where long-term zero-maintenance re- liability is necessary, and contact corrosion could be a risk in electromagnetic relays). Small solid- state relays can switch motors in robots or appliances where vibration is common, and are often used in arcade games.

What Can Go Wrong

Overheating Caused by Overloading

Relays must be derated when used at operating temperatures above the typical 20 or 25º C for which their specification applies. In other words, the sustained operating current must be reduced, usually by an amount such as 20% to 30% for each 10-degree increase in ambient temperature. Failure to observe this rule may result in failure of the component. Burnout may also occur if a high-current solid-state relay is used without a heat sink, or the heat sink isn’t big enough, or thermal compound is not applied be- tween the solid-state relay and the heat sink.

Overheating Caused by Bad Terminal Contact

If the screw terminals on the output side of a high-current solid-state relay are not tightened sufficiently, or if there is a loose spade terminal, or if a crimped connection isn’t crimped tightly enough, the poor contact will create electrical resistance, and at high currents, the resistance will create heat, which can cause the solid-state relay to overheat and burn out.

Overheating Caused by Changing Duty Cycle

If a high-current solid-state relay is chosen for an application where it is in its “on” state only half the time, but the application changes during product development so that the solid-state re- lay is in its “on” state almost all the time, it will have to dissippate almost twice as much heat. Any time the duty cycle is changed, heat should be considered. The possibility of the relay being used in an unconventional or unexpected manner should also be considered.

Overheating Caused by Component Crowding

Overheating increases dramatically when components are tightly crowded. At least 2cm (3/4”) should be allowed between components.

Overheating in Dual Packaging When a package contains two solid-state relays, the additive effects of the heat created by each of them must be considered.

Reverse-Voltage Burnout

Because a solid-state relay is more sensitive to back-EMF than an electromagnetic relay, greater care should be used to protect it from reverse voltage when switching inductive loads. A protection diode should be used, and a snubber can be added between its output terminals, if it is not included inside the relay package.

Low Voltage Output Current May Not Work

Unlike electromagnetic relays, solid-state relays require some voltage on the output side to en- able their internal operation. If there is no volt- age, or only a very low voltage, the SSR may not respond to an input. The minimum voltage required on the output side is usually specified in a datasheet.

To test a solid-state relay, apply actual voltages on input and output sides and use a load such as an incandescent light bulb. Merely applying a meter on the output side, set to measure continuity, may not provide sufficient voltage to en- able the relay to function, creating the erroneous impression that it has failed.

Inability to Measure AC Output When a multimeter is used to test continuity across the output of an AC-switching solid-state relay of zero-crossing specification, the meter

will generate enough voltage to prevent the solid-state relay from finding zero voltage across its output terminals, and consequently the solid- state relay won’t switch its output.

Relay Turns On but Won’t Turn Off When a solid-state relay controls a relatively high-impedance load such as a small solenoid

(see Volume 1) or a neon bulb (see Chapter 19), the relay may switch the device on but will seem unable to switch it off. This is because the leakage current of the solid-state relay, in its “off” state, may be just enough to maintain the load in its “on” state.

If an SSR containing a triac is used erroneously to switch DC, it will not be able to switch off the current.

Relays in Parallel Won’t Work

Two solid-state relays usually cannot be used in parallel to switch twice as much current. Because of small manufacturing variances, one relay will switch on a moment before the other. When the first relay is on, it will divert the load current away from the second relay. The second relay needs a small amount of current on its output side, to function. Without any current, it will not switch on. This means the first relay will pass the total current without any help from the second relay, and will probably burn out, while the second re- lay does nothing.

Output Device Doesn’t Run at Full Power

A solid-state relay imposes a voltage reduction on its output side. This will be a fixed amount, not a percentage. When switching 110V, this difference may be negligible; when switching 12V, it may deliver only 10.5V, which represents enough of a drop to cause a motor or a pump to run noticeably more slowly. The internal switching de- vice inside the relay (MOSFET, triac, SSR, or bipolar transistor) will largely determine the voltage drop. Check the manufacturer’s datasheet before using the relay.

Solid-State Relays and Safety Disconnects

Because a solid-state relay always allows some leakage in its “off” state, it can still deliver a shock when used to switch high voltages. For this reason, it may not be suitable in a safety disconnect.