LED area lighting

The term LED area lighting is used in this encyclopedia to describe a white LED source that is bright enough to illuminate rooms, offices, or outdoor areas. It may also be used in desk lamps or table lamps as task lighting. LEDs for these purposes may be categorized as high-brightness, high-power, high-output, or high-intensity. A complete fixture containing at least one light source is properly known as a luminaire, although the term is not uniformly applied and is sometimes written incorrectly as a luminary.

The full term light-emitting diode is not normally applied to an LED used for area lighting. For this purpose, the LED acronym has become universal. Periods are not normally placed between the letters.

While an LED area-lighting package may contain more than one diode, it is still categorized here as a single source. By contrast, any component consisting of multiple separately discernible light-emitting diodes, as in a seven-segment numeral, a 14- and 16- segment alphanumeric character, a dot-matrix character, or a display of multiple characters, is listed in a separate entry as an LED display.

The term OLED is an acronym for Organic Light-Emitting Diode, a thin panel in which an organic compound is contained between two flat electrodes. Despite its functionality as a form of LED, its design is similar to that of thin-film electroluminiscent light sources. Therefore it is discussed in the entry on electroluminescence.

What It Does

High-brightness white LEDs provide a plug- compatible alternative to incandescent lamps, halogen lighting, and fluorescent lights for work spaces and the home.

At the time of writing, products are still evolving rapidly in the field of LED area lighting. A shared goal of manufacturers is to increase efficiency while reducing retail price to the point where high-brightness LEDs will displace fluorescent tubes for most low-cost lighting applications.

A wall-mounted LED reflector-bulb that emulates a halogen fixture is shown in Figure 23-1. A small LED floodlight for exterior use is shown in Figure 23-2. An early attempt to package an LED area light in a traditional-style bulb is shown in Figure 23-3. Within a decade, as LED area lighting continues to evolve, some of these examples

may look quaint. Configurations are evolving, with final results that remain to be seen.

Figure 23-1. A small LED reflector-light emulating a halo- gen fixture. Note the square of yellow phosphors mounted on the diode.

Figure 23-2. A floodlight for exterior use. Nine LEDs are assembled behind the yellow phosphors. The steel frame measures about 4” by 3”.

Trends in Cost and Efficiency

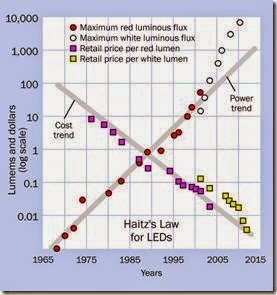

The luminous flux of a source is the total power that it radiates in all directions, within the visible spectrum. The unit that measures luminous flux is the lumen. For a more detailed discussion of

this topic, see “Power” on page 177. Since 1965, the cost per lumen of light from a given color of LED has decreased by about a factor of 10, while the maximum number of lumens emitted by an LED package has increased by a factor of 20, dur- ing each decade. This is known as Haitz’s Law, named after Dr. Roland Haitz of Agilent Technol- ogies. Figure 23-4 illustrates it graphically.

Figure 23-3. An LED light bulb. Unlike an incandescent bulb, it focuses the illumination in one direction, like a reflector-light. Consuming only 6W, it is claimed to be equivalent to a 40W incandescent bulb.

Schematic Symbol

Schematic symbols that are commonly used to represent an LED are shown in Figure 23-5. The symbol remains the same regardless of the size or power of the component, but architectural plans may represent any type of light using the circle-and-X symbol at bottom right.

How It Works

A high-brighteness LED functions on the same basis explained in the entry describing LED in- dicators. Photons are emitted when electrons are sufficiently energized to cross a PN junction and combine with electron-holes.

An LED that appears white, or off-white, actually emits blue light that is re-radiated over a wide range of wavelengths by adding a layer of yellow phosphors to the chip. A cutaway diagram of an LED chip (properly known as a die), mounted un- der a silicone lens, is shown in Figure 23-6.

Figure 23-4. The increase in light output (luminous flux, in lumens) of a single LED compared with the decrease in cost-per-lumen during the years since 1965. The vertical logarithmic scale measures both dollars and lumens. Source: Philips Gardco site-lighting fact sheet with additional data from a “Strategies in Light Report” published by Semiconductor Equipment and Materials International in 2013.

Figure 23-5. The symbol for an LED remains the same re- gardless of its size and power, but architectural plans may use the circle-and-X symbol at bottom right for any type of light fixture.

LEDs are mass-produced by etching them into crystals that are then cut into wafers before being subdivided into dies, like silicon chips. Most of the blue LEDs that form the basis of white lighting use sapphire crystals as their substrate. The crystal may range in diameter from two inches to six inches. Large sapphire wafers are also finding potential applications in camera lens covers and scratch-resistant cover plates for cellular phones.

Figure 23-6. Cutaway diagram of a high-brightness white LED. Adapted from Philips Lumileds Technical Reference document.

While a die for an LED indicator may be 0.3mm x 0.3mm, a die in a high-brightness LED is often 1mm x 1mm. The size is limited by technical is- sues involving total internal reflection of the generated light.

The precise color of the light is adjusted by adding red phosphors to the yellow phosphors. This reduces the overall efficiency of the LED by around 10% but creates a “warmer” radiance. A graphical illustration of this principle is shown in Figure 22-3, in the entry on LED indicators.

The color temperature of white or offwhite light is measured in degrees Kelvin, typically ranging from 2,500K to 6,500K, where a lower number represents a light with more red in it and a higher number represents a light with more blue in it. This system of measurement was originally used with incandescent bulbs to define the temper- ature of the filament, which determined its color. See “Spectrum” on page 173 for a detailed ex- planation.

Visible Differences

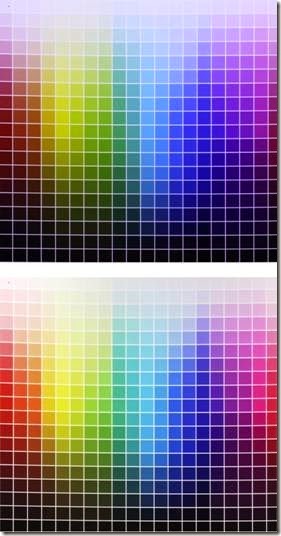

The effects of different types of illumination are compared in Figure 23-7. To create this figure, first a color chart was prepared in Photoshop and printed on high-gloss photo-grade paper with a Canon Pro9000 Mark II inkjet printer, which has separate colors for red and green in addition to cyan, pale cyan, magenta, pale magenta, yellow, and black.

The color chart was then photographed twice with a Canon 5D Mark II, using a fixed white balance of 4000K. The first exposure was made with “daylight spectrum” LED lighting (claimed color temperature of 6500K) while the second was made with halogen lighting (claimed color temperature of 2900K). The photographs were adjusted in Photoshop for levels only, to fill the available range of 256 values. The two exposures show how the same chart would appear when viewed under the different lights, if the human eye did not adjust itself at all. Note the large area of the LED exposure which is rendered in shades of blue or purple. Also note the dullness of the reds. This confirms the everyday belief that “day- light spectrum” LEDs tend to have a cold, purplish cast while incandescents have a warmer, yellow look.

The same camera was then used to make two more exposures, this time with the white balance set to 6500 for LED lighting and 2900 for halogen lighting, which would be the recommended standard procedure, suggesting the kind of com- pensation that the human eye also tends to make for different ambient lighting. The result is shown at Figure 23-8. The LED version has improved, but the reds and yellows are still muted. The halogen version also looks better than before, but the magenta end of the spectrum has too much yellow in it. These images show the limits of white- balance correction for indoor photography.

Figure 23-7. The same printed color chart viewed with “daylight white” LEDs (top) and halogen lighting (bot- tom), without any compensation to allow for the different light spectra. A fixed white balance of 4000K was used for both pictures.

Side-by-Side Comparison

Because the human eye is much better at com- paring colors when they are adjacent to each other, another color chart was prepared using just six color bars of fully saturated red, yellow, green, cyan, blue, and magenta, with paler and darker versions above and below. The bars were separated with large white gaps. The chart was photographed first with the white balance set to 6500 under “daylight white” LED lighting and then again with the white balance at 2900 for halogen lighting. In Photoshop, the bars from the halogen version were copied and pasted beside the bars from the LED version to facilitate an A-B comparison. The result is shown in Figure 23-9.

Figure 23-8. The same color chart as before, photo- graphed with appropriate color temperature settings of 6500K (top, using “daylight-spectrum” LEDs) and 2900K (bottom, using halogen).

In each pair of colors, LEDs lit the one on the left, and halogen lights lit the one on the right. This figure shows the dramatic difference at the red end of the spectrum, and the poor reproduction of yellows by LED lighting. However, the LED rendering of green is better, and likewise the rendering of magenta, except where its darker version is concerned. Among the pale versions of the colors, the LED lights produce much less density (i.e., they have a brighter look) in the blues, greens, and cyans. The low densities will show up as pale highlights in a photograph of an object, and the picture will tend to have excessive co trast. This will also contribute to the “harsh” look of “daylight white” LED lighting which may be perceived by the eye.

Figure 23-9. A range of six fully saturated colors, with lighter and darker shades added above and below, photo- graphed first with “daylight spectrum” LEDs and then with halogen lights, after which the two sets of colors were paired for easy comparison. The LED version is on the left in each pair.

Halogen is deficient at the blue-violet end of the spectrum, even when the camera has an appropriate white-balance setting. Photographers can correct this using image-editing software. LED “daylight spectrum” lights are more difficult to correct. LEDs classified as “warm” should repro- duce reds better, but may not do so well with blues.

Diffuse light from a uniformly cloudy sky may be the most ideal form of lighting for photographing objects, but this is of little help for people who work (or take photographs) under artificial lights.

LED lights that contain separate red, green, and blue emitters may perform better, but create a different problem, in that shadows will tend to have color fringes caused by the small offsets between the colored emitters.

Heat Dissipation

An LED is less than 100% efficient because not all electrons mate with electron holes. Some man- age to bypass the semiconductor junction; some recombine without generating light; and some transfer their energy to other atoms. In each in- stance, waste heat is created. While the heat in an incandescent bulb is mostly dissipated by ra- diation, an LED must get rid of the heat almost entirely by conduction, typically through a heat sink. This complicates the design of a fixture, be- cause the integrity of the pathway to dispose of the heat must be retained when the LED bulb or tube is replaced.

Efficacy

The radiant luminous efficacy (LER) of an incandescent light source measures how effective it is at channeling its output within the visible spectrum instead of wasting it in infrared radiation. LER is expressed in lumens per watt, and in an incandescent bulb, it is calculated by dividing the power emitted in the visible spectrum (the luminous flux) by the power emitted over all wave- lengths. This is described in detail in “Efficacy” on page 179 in the entry dealing with incandescent lamps.

In an LED indicator, almost all the radiation can be contained within the visible spectrum, which suggests that its efficacy should be 100%. How- ever, because some waste heat is still created internally, the efficacy is calculated by dividing the light output, in lumens, by the power input, in watts, at the voltage required by the LED. (Lumens can be converted directly to watts, and therefore this division makes a comparison be- tween similar units).

In an LED lighting fixture that contains its own electronics to convert higher voltage AC to lower voltage DC, the power consumption of the fixture is measured not at the diode, but at the input side of the electronics. Therefore, the inefficiency of the electronics reduces the efficacy value of the lighting unit.

Dimming

An incandescent bulb is very sensitive to reduction in power. It becomes radically inefficient, emitting perhaps 1% of its normal light output if the power is reduced to 40%.

LEDs have an almost linear response to the sup- plied power. Usually a triac-based dimmer will not work well with LED area lighting, and a dimmer designed for LEDs must be substituted, using pulse-width modulation.

Ultraviolet Output

The gas plasma in a fluorescent light generates ultraviolet wavelengths that are shifted to the visible spectrum by the phosphor coating inside the glass envelope. Imperfections in the phosphor coating can potentially allow leakage of ultraviolet light, causing some researchers to claim that the use of CFLs (compact fluorescent lighting) for close-up work with desk lamps can in- crease the risk of developing some forms of skin cancer. (This claim remains controversial.)

LED manufacturers are quick to point out that white LEDs do not emit any ultraviolet radiation. Figure 23-10 shows spectral power distribution curves derived from measurements of three high-brightness Color Kinetics LEDs manufactured by Philips. The manufacturer states categorically that “The LED-based color and white light products made by Color Kinetics do not emit outside the visible spectrum.” Infrared radiation is also negligible.

Color Variation

The correlated color temperature (CCT) is deter- mined by finding the conventional incandescent color temperature which looks most similar to the light from a white LED. Unfortunately, be- cause the CCT standard is insufficiently precise,

and because small manufacturing inaccuracies can occur, two LED sources with the same CCT number may still appear different when they are side by side. While the human eye adjusts itself to overall color temperature, it is sensitive to differences between adjacent sources. If two or more white LEDs in a lighting fixture do not have identical spectra, the difference will be noticeable.

Figure 23-10. Spectral power distribution curves for three high-brightness white LED lamps showing no ultraviolet emissions. (Adapted from a graph in a white paper published by Color Kinetics Incorporated.)

To address the issue, manufacturers introduced the concept of “binning,” in which lights are sub- classified to tighter specifications and are as- signed bin numbers based on their measured characteristics. The Philips Optibin system, for instance, assesses the light from various angles, as well as perpendicularly to the source. This is especially important where a large area such as a building lobby is painted white and is lit by high-brightness LEDs that must appear uniform in color temperature.

Variants

LED area lighting products are often designed to emulate the form factors of incandescent bulbs, halogen reflector bulbs, or fluorescent tubes. The standard screw-in base of an LED light bulb, the pin-base of a miniature 12V LED reflector bulb, and the pins on an LED tube enable easy migration to the newer technology.

Strip lights are unique to LED lighting systems. They are thick, flexible plastic ribbons in which are embedded a series of LEDs. For area lighting, the LEDs are white, and the strips can contain necessary control electronics for conversion of AC power. The strips can be placed behind ledges or moldings to provide soft, even illumination of the ceiling above.

Strip lights are also available for 12VDC power, to create lighting effects in customized automobiles and trucks. These strip lights are available in various colors in addition to white. Many have multicolor capability and can be controlled with a handheld remote.

Comparisons

The advantages of an incandescent lamp are listed in “Relative Advantages” on page 179, while advantages of fluorescent lights are listed in “Comparisons” on page 194. These lists can be compared with the following advantages for LED area lighting:

• While the life of an incandescent lamp for room lighting can be as little as 1,000 hours, LED area lighting typically claims up to 50,000 hours.

• The lifetime of an incandescent bulb is the average time it can emit light before cata- strophic failure. The lifetime of an LED is the average time it can emit light before gradu- ally dimming to 70% of its rated output. This is a much gentler, less inconvenient failure mode that does not require immediate re- placement.

• Unlike a fluorescent light or incandescent bulb, the LED does not contain hot tungsten that fails as a result of erosion.

• Unlike a fluorescent light, an LED does not contain mercury, and therefore does not re- quire special recycling arrangements that entail associated fees.

• While fluorescents can have difficulty starting in low temperatures, an LED is not sensitive to a cold environment.

• Bright LEDs are available in a wide range of colors that do not require filtering. Filters greatly reduce the efficiency of incandescent bulbs when they are used in applications such as traffic signals or rear lights on automobiles.

• High-brightness LEDs can be dimmable. Flu- orescent lights are usually not dimmable, or perform poorly in this role.

• LEDs are inherently directional, because the die radiates light at an angle of 90 degrees to its plane. This makes it ideal for ceiling mounting, where as much light as possible should be directed downward. A fluorescent tube or incandescent bulb often requires a reflector which reduces the overall efficiency.

• LEDs are insensitive to cycling. The life expectancy of an incandescent bulb or (especially) a fluorescent tube is reduced by cy- cling it on and off.

• No flickering. Fluorescent tubes may start to flicker as they age.

• No electrical interference. Fluorescent tubes can interfere with AM radio reception and some audio devices.

• Safe from breakage. LED area lighting does not necessarily use any glass.

However, high-brightness LEDs still have some barriers to overcome:

• Cost. In the United States, before 60W incandescent bulbs were legislated out of existence, they could be sold profitably for less than $1 each. A T8 fluorescent tube, measuring 1” diameter and 48” long, currently costs between $5 and $6 (retail) but has a life expectancy in the region of 25,000 hours, and uses only 20% of the power of an incan- descent bulb to generate two to three times as much light. Clearly the fluorescent tube is a more economical choice, despite the price of the electronics that must be included in the fixture to start the tube. By comparison, currently the purchase price of an LED tube is three times that of a fluorescent tube. It may last twice as long, but is not significantly more efficient, generating perhaps 100 lumens per watt while a fluorescent is typically capable of 90 lumens per watt. Prototype high-brightness LEDs have exceeded 200 lumens per watt, and should be competitive with fluorescents by 2020, but even then, migration will take time.

• Heat sensitivity. Heat reduces the light out- put and the lifespan of LED fixtures.

• Placement issues. Because LEDs are heat sensitive, they must be installed in locations that do not become excessively hot, their heat sinks must be correctly oriented, and they must have adequate ventilation.

• Color shift. Heat and age may cause the color temperature of an LED to shift slightly, as the color is usually derived from two types of phosphors.

• Nonuniformity. Manufacturing inconsistencies can cause LEDs of the same type to dis- play slightly different color temperatures. Fluorescents and incandescents are more uniform.

• Lower heat output than incandescents. While this is an advantage from the point of view of efficiency, it can be a disadvantage in applications such as traffic signals or air- port runway lighting where waste heat can help to keep the lights free from snow or ice.

Values

Although the output from an LED area light is directional, while the output from an incandes- cent bulb or a fluorescent light is omnidirection- al, the intensity is measured the same way in each instance, using lumens. This unit expresses the total light emission, without taking directionality into account. (The intensity of LED indicators is calibrated in candelas, which measure the power within an angle of dispersion; but candelas are not used for area lighting.)

Typical values for incandescent bulbs are 450 lmens for a power consumption of 40 watts, 800 lumens for a consumption of 60 watts, 1,100 lumens for a consumption of 75 watts, and 1,600 lumens for a consumption of 100 watts. Because much of the output from an incandescent bulb may be wasted by using inefficient reflectors or allowing the light to shine in directions where it is not needed, a high-brightness LED rated at 1,000 lumens may actually appear brighter than a 75-watt incandescent bulb.

A T8 fluorescent tube measuring 48” long by 1” in diameter consumes only 32 watts but emits almost 3,000 lumens—when it is new. This out- put gradually diminishes by as much as 40% over the lifetime of the tube.

Incandescent bulbs deliver between 10 and 15 lumens per watt, approximately. A new fluorescent tube produces around 80 to 90 lumens per watt, and LED area lighting at the time of writing can provide 100 lumens per watt, under real- world conditions.

What Can Go Wrong

Wrong Voltage

Many high-brightness LED lighting units can be used with either 115VAC or 230VAC. There are exceptions, however. Check the specifications to make sure. Also, it is important to avoid applying domestic supply voltage to 12V LED miniature reflector-bulbs that are intended to replace 12VAC halogen bulbs of the same size.

Overheating

If a high-brightness LED fixture is equipped with a heat sink, this must be exposed to freely flowing air. Any vanes on the heat sink should be oriented vertically to encourage convection, and the fixture must not be placed in an enclosure. Overheating will radically shorten LED life.

Fluorescent Ballast Issues

A fluorescent fixture contains a ballast to limit the tendency of the tube to draw excessive current. The ballast is contained in a plastic box attached to the back of the frame in which the tube is mounted.

A magnetic ballast contains a coil, and is by- passed by an additional starter that applies un- limited current for one second when the power is switched on, preheating the tube to initiate plasma discharge.

An electronic ballast performs the same function without a separate starter.

Some LED tubes designed as substitutes for fluorescent tubes may allow a magnetic ballast to remain in the circuit, but may not tolerate an electronic ballast. Other LED tubes require any type of ballast to be unwired from the circuit. The unwiring operation will require disconnection of a couple of wires by removing wire nuts (assuming that the fixture has been designed to comply with U.S. building codes). The wires are then re- connected to apply power directly to the tube, and the wire nuts are reapplied to complete the new connection. The ballast can remain passively in the fixture.

Failing to remove the ballast and/or the starter from a fluorescent fixture before installing an LED tube that requires direct connection to the power supply can damage the tube. Connecting the power incorrectly to the LED tube may result in it failing to light up. Documentation supplied with the LED tube should provide guidance for disconnecting the ballast and connecting the tube. Note that the pin functions on LED tubes are not standardized at this time.

Misleading Color Representation Because the spectrum of a white LED is not evenly weighted across all wavelengths, it will fail to represent some colors accurately, as shown previously. This can be important if LEDs are used to illuminate full-color printing or artwork, or if they are installed in stores selling merchandise such as clothes, furnishings, or food.