incandescent lamp

The terms incandescent light, incandescent bulb, and incandescent light bulb are often used interchangeably with incandescent lamp. Because the term “lamp” seems to be most common, it is used here. A panel-mounted indicator lamp is considered to be an assembly containing an incandescent lamp.

A carbon arc, which generates light as a self-sustaining spark between two carbon electrodes, can be thought of as a form of incandescent lamp, but is now rare and is not included in this encyclopedia.

What It Does

The term incandescent describes an object that emits visible light purely as a consequence of being hot. This principle is used in an incandescent lamp where a wire filament glows as a result of electric current passing through it and raising it to a high temperature. To prevent oxidation of the filament, it is contained within a sealed bulb or tube containing an inert gas under low pres- sure or (less often) a vacuum.

Because incandescent lamps are relatively inefficient, they are not considered a wise environ- mental choice for area lighting and have been prohibited for that purpose in some areas. How- ever, small, low-voltage, panel-mount versions are still widely available. For a summary of ad- vantages of miniature incandescent lamps relative to light-emitting diodes (LEDs) see “Relative Advantages” on page 179.

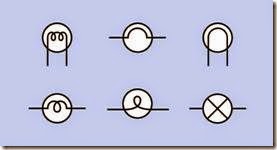

Schematic symbols representing an incandescent lamp are shown in Figure 18-1. The symbols are all functionally identical except that the one at bottom right is more likely to be used to rep- resent small panel-mounted indicators.

Figure 18-1. A variety of symbols can represent an incandescent lamp. The one at bottom right may be more commonly used for small panel-mounted indicators.

The parts of a generic incandescent light bulb are identified in Figure 18-2:

A: Glass bulb.

B: Inert gas at low pressure.

C: Tungsten filament.

D: Contact wires (connecting internally with brass base and center contact, below).

E: Wires to support the filament. F: Internal glass stem.

G: Brass base or cap. H: Vitreous insulation. I: Center contact.

Figure 18-2. The parts of a typical incandescent lamp (see text for details).

History

The concept of generating light by using electricity to heat a metal originated with English- man Humphrey Davy, who demonstrated it with a large battery and a strip of platinum in 1802. Platinum was thought to be suitable because it has a relatively high melting point. The lamp worked but was not practical, being insufficiently bright and having a short lifespan. In addition, the platinum was prohibitively expensive.

The first patent for an incandescent lamp was is- sued in England in 1841, but it still used platinum. Subsequently, British physicist and chemist Joseph Swan spent many years attempting to develop practical carbon filaments, and obtained a patent in 1880 for parchmentized thread. His house was the first in the world to be illuminated by light bulbs.

Thomas Edison began work to refine the electric lamp in 1878, and achieved a successful test with a carbonized filament in October 1879. The bulb lasted slightly more than 13 hours. Lawsuits over patent rights ensued. Carbonized filaments were used until a tungsten filament was patented in 1904 by the German/Hungarian inventor Just Sándor Frigyes and the Croatian inventor Franjo Hanaman. This type of bulb was filled with an inert gas, instead of using a vacuum.

Many other pioneers participated in the effort to develop electric light on a practical basis. Thus it is incorrect to state that “Thomas Edison invented the light bulb.” The device went through a very lengthy process of gradual refinement, and one of Edison’s most significant achievements was the development of a power distribution system that could run multiple lamps in parallel, using filaments that had a relatively high resistance. His error was insisting on using direct cur- rent (DC) while his rival Westinghouse pioneered alternating currrent (AC), enabling power trans- mission over longer distances through the use of transformers. The use of AC also enabled Tesla’s brushless induction motor.

By the mid-1900s, most incandescent bulbs used tungsten filaments.

How It Works

All objects emit electromagnetic radiation as a function of their temperature. This is known as black body radiation, based on the concept of an object that absorbs all incoming light, and thus does not reflect any sources from outside itself. As its temperature increases, the intensity of the radiation increases while the wavelength of the radiation tends to decrease.

If the temperature is high enough, the wave- length of the radiation enters the visible spec- trum, between 380 and 740 nanometers. (A nanometer is one-billionth of a meter.)

The melting point of tungsten is 3,442 degrees Celsius, but a lamp filament typically operates between 2,000 and 3,000 degrees. At the higher end of this scale, evaporation of metal from the filament tends to cause deposition of a dark residue on the inside of the bulb, and erodes the filament more rapidly, to the point where it eventually breaks. At the lower end of this scale, the light will be yellow and the intensity will be reduced.

Spectrum

The color of black-body radiation is measured using the Kelvin temperature scale. The increment of 1 degree Kelvin is the same as 1 degree Celsius, but the Kelvin scale has a zero value at absolute zero. This is the theoretical lowest conceivable temperature, at which there is complete absence of heat. It is approximately –273 degrees Celsius.

From this it is evident that if K is a temperature in degrees Kelvin and C is a temperature in degrees Celsius:

K = C + 273 (approximately)

Calibration of light sources in degrees Kelvin is common in photography. Many digital cameras allow the user to specify the color temperature of lights that are illuminating an indoor scene, and the camera will compensate so that the light source appears to be pure white with all colors in the visible spectrum being represented equally.

Some computer monitors also allow the user to specify a white value in degrees Kelvin.

Color temperature is used in astronomy, because the spectrum of many stars is comparable with that of a theoretical black body.

A color temperature of 1,000 degrees K will have a dark orange hue, while 15,000 degrees K or higher will have a blue hue comparable to that of a pale blue sky. The color temperature of the sun is approximately 5,800 K. Interior lighting is often around 3,000 K, which many people find acceptable because it creates pleasant flesh tones. An incandescent bulb described by the manufacturer as “soft white” or “warm” will have a lower color temperature than one which is sold as “pure white” or “paper white.”

Graphs showing the emission of wavelengths at various color temperatures are shown in Figure 18-3. The rainbow section indicates the approximate range of visible wavelengths be- tween ultraviolet, on the left, and infrared, on the right. For purposes of clarity, the peak intensity for each color temperature has been equalized. In reality, increasing the temperature also increases the light output.

Figure 18-3. Approximate peak wavelengths for black- body radiation at various color temperatures in degrees Kelvin. The curves have been adjusted so that their peak values are equalized. Adapted from an illustration in the reference book Light Emitting Diodes by E. Fred Schubert.

Non-Incandescent Sources

So long as light is generated by heating a filament, plotting the intensity against wavelength will result in a smooth curve without irregularities. A higher Kelvin value will simply displace and compress the curve laterally without changing its basic shape to a significant degree.

The introduction of fluorescent sources and, subsequently, light-emitting diodes (LEDs) has complicated this scenario. Because they are luminescent rather than incandescent, they do not generate an evenly weighted, continuous range of wavelengths.

LEDs tend to emit monochromatic light, meaning that it is tightly centered around just one col- or. A “white” LED is really a blue LED in which a phosphor coating on the semiconductor die is excited to create light over a broader range. A fluorescent light tends to create spectral lines which show up as sharp peaks at a few wave- lengths determined by the mercury inside the bulb. Figure 18-4 illustrates these problems.

The human eye tends to compensate for the yellow emphasis of incandescent lamps and for the irregularities in spectra emitted by other light sources. Also, the eye is often unable to distinguish between “white” light created as a mix of all the visible wavelengths, and light that appears white even though it is dominated by a few isolated wavelengths from a fluorescent source.

However, when the eye views colors that are illuminated by a source that has gaps in its spectrum, some of the colors will appear unnaturally dull or dark. This is true also if an imperfect source is used as a backlight to create colors on a video monitor. Colors rendered by different light sources are shown in Figure 23-7 and subsequent figures.

Figure 18-4. The relative performance of three light sources compared with sensitivity of the human eye to the visible spectrum. Note that the range of wavelengths on the horizontal scale in this figure is not the same as the range in the previous figure. The color assigned to each curve is arbitrary. Adapted from VU1 Corporation.

Photography is adversely affected by the use of LEDs or fluorescents as a light source. Reds, for example, can seem dark when lit by white LEDs, while blues can be inappropriately intense. Be- cause the source does not have an emission curve comparable to that of an incandescent light, the auto-white balance feature of a digital camera may be unable to address this problem, and it cannot be resolved by entering a different Kelvin number manually.

The fidelity with which a light source is capable of displaying the full visible spectrum is known as the color rendering index (CRI), ranging from a perfect score of 100 down to 0 or even lower (sodium-vapor street lighting has a negative val- ue). Computing the index requires standard reference color samples and has been criticized for generating scores that do not correlate well with subjective assessments.

Incandescent bulbs can have a CRI of 100, while an uncorrected “white” LED may score as low as 80.

Power Consumption

Approximately 95% of the power consumed by an incandescent lamp generates heat instead of visible light. This wastage of power in room lighting is compounded by the power consumption of air conditioning to remove the heat from en- closed spaces in hot climates. While the heat from incandescent lamps does reduce the need for space heating in cold environments, heat is delivered more efficiently by using systems de- signed for that purpose. Consequently, greater energy efficiency can be achieved with a light source that generates less heat, regardless of ambient air temperature.

Variants

Miniature Lamps

Prior to the development of LEDs, all light- emitting panel-mounted indicators were either neon bulbs or incandescent lamps. The use of neon is limited by its need for a relatively high voltage.

Miniature incandescents were the traditional choice for battery-powered light sources, and at the time of writing are still used in cheap flash- lights. Variants are available that are as small as a 5mm LED, with a claimed life expectancy that is comparable, although they draw more current to generate an equivalent light intensity, because much of their power is wasted in infrared wave- lengths.

The photograph in Figure 18-5 is of a miniature lamp terminating in pins spaced 0.05” apart. The total height of the lamp, including its ceramic base, is less than 0.4,” while its diameter is just over 0.1”. It draws 60mA at 5V and is rated for 25,000 hours.

The photograph in Figure 18-6 is of a lamp of similar size and power consumption, but terminating in wire leads and rated for 100,000 hours. It emits 0.63 lumens.

Figure 18-5. A miniature lamp less than 0.4” high, terminating in pins spaced 0.05” apart.

Figure 18-6. This lamp is 0.25” high and terminates in wire leads.

Figure 18-6. This lamp is 0.25” high and terminates in wire leads.

The lamp pictured in Figure 18-7 is slightly larger, with a glass envelope about 0.25” diameter. It is rated for less than half the lifetime of the lamp in Figure 18-6 but emits three times as much light

—a typical tradeoff. Various base styles are avail- able.

Figure 18-7. This lamp has a glass envelope about 0.35” high. Its screw-in base makes it easier to replace than an LED.

In the United States, the light output from miniature incandescent lamps may be measured in lumens, but is more often rated in mean spherical candlepower (MSCP). An explanation of light measurement is included in “MSCP” on page 178.

Lamp lenses provide a quick and simple way to add color to a miniature incandescent lamp. Usually the lens is cylindrical with a hemispherical end cap, and is designed to push-fit or snap-fit over a small lamp. Even when the cap is translucent, it may still be referred to as a lens.

Panel-Mount Indicator Lamps

This term often refers to a tubular assembly containing a miniature lamp, ready for installation.

The enclosure is often designed to snap-fit into a hole drilled in the panel. If the incandescent bulb inside the enclosure cannot be replaced, the component is said to be “non-relampable.” Figure 18-8 shows a 12-volt panel-mount indicator lamp.

Figure 18-8. This panel-mount indicator lamp is designed to push-fit into a hole 1/2” in diameter. The bulb inside it is not replacable, causing the assembly to be classified as “non-relampable.”

Halogen or Quartz-Halogen

This is a type of incandescent lamp containing gases under pressure in which halogens such as iodine or bromine cause evaporated tungsten atoms to be redeposited on the filament. A halogen lamp can therefore operate at a higher temperature, creating a light that is less yellow and brighter than that from a comparable incandescent lamp. It also enables a smaller bulb, but requires an envelope of borosilicate-halide glass (often termed fused quartz) instead of regular glass. A halogen lamp will be slightly more efficient than an incandescent bulb of the same wattage, and will last longer.

Halogens are available in a variety of formats. The small bulb pictured in Figure 18-9 consumes 75W, emitting 1,500 lumens at 3,000 degrees Kelvin. The light intensity is claimed to be equivalent to that of a 100W incandescent bulb. It has a mini-candelabra base.

Oven Lamps

Oven lamps are designed to withstand the high temperature in an oven. Typically they are usable with ambient temperatures up to 300 degrees C. A common power rating is 15W.

Figure 18-9. A halogen bulb slightly more than 2” in length, designed for 115VAC.

Base Variants

Miniature lamps are available with a wide variety of connection options, including wire terminals, single-contact bayonet, double-contact bayonet, miniature screw base, and fuse style. Most of these options require a matching socket.

Screw-in lamps for room illumination are common in household lighting in the United States and many other countries (but not in the UK, where bayonet fittings are used). The US socket size is designated by letter E followed by a number that gives the socket diameter in millimeters. Common sizes are E10, E14 and E27.

A bayonet base is fitted with two small lugs protruding on opposite sides. The lamp is secured by pushing it in and twisting it to engage the lugs in slots in the socket. The advantage of a bayonet

base is that the bulb is less likely to become loose as a result of vibration.

A pin base consists simply of a pair of pins that will push-fit into small holes in a socket.

A flange base has a flange that engages in a sock- et where flexible segments will retain it.

A wedge base is forced between two contacts which retain the bulb by friction.

Some indicator lamps terminate simply in long, thin leads that can be soldered.

Values

While the power consumption of full-size incandescent lamps is rated in watts, small indicator lamps are rated in milliamps at the voltage for which they are designed. Miniature lamps may require specific voltages ranging from as low as 2V to 24V. A higher voltage generally necessitates a longer filament, which may entail a larger bulb.

The light that a lamp will emit can be measured in two ways: either as the power of the lamp (not its power consumption, but its radiating power), or as the light delivered to a specific area at a specific distance. These two measurements may differ because a lamp may concentrate its light in a beam, as in the case of a reflector bulb or an LED.

Power

Flux, in watts, is a measurement of energy flow in joules per second. The total radiating power of a lamp, in all wavelengths, in all directions, is known as its radiant flux. Because invisible wave- lengths are of little interest when assessing the brightness of a lamp, the term luminous flux is used to describe the apparent brightness of the lamp in the visible spectrum. The unit for luminous flux is the lumen.

The human eye is most responsive to yellow- green hues in the center of the spectrum. Consequently, the measurement of luminous flux is weighted toward green at a wavelength of 555 nanometers. Red and violet are considered to have low luminous flux, while infrared and ultra- violet have a zero value.

When considering a value expressed in lumens, remember:

• Lumens are a measure of the total radiated power output of a light source, in all directions, in the visible spectrum only, weighted toward the characteristics of the human eye.

• The number of lumens of a light source does not define the direction in which the light is shining, or its uniformity.

• The abbreviation for lumen is lm.

A conventional incandescent lamp that consumes 100W of electricity is likely to have a light output of about 1,500 lumens. A 40W fluorescent tube can have a light output of about 2,600 lumens.

Illuminance

The illuminance of a light source is defined as the luminous flux per unit of area. This can be thought of as the brightness of a surface illuminated by the source.

Illuminance is measured in lux, where 1 lux = 1 lumen per square meter. For accurate calibration, the illuminated surface should be spherical in shape, and must be located 1 meter from the light source, with the source at the geometrical center of the sphere.

Illuminance used to be measured in foot- candles, where 1 foot-candle was 1 lumen per square foot.

• The number of lumens per square meter (lux) does not define the size of the illuminated area, only the brightness per unit of area.

• A lamp that has a tightly focused beam can achieve a high lux rating. When selecting a lamp for an application, the angle of dispersion of the beam must be considered in con- junction with its lux rating.

Intensity

A candela measures the luminous flux within an angle of dispersion. The angle is three- dimensional, and can be imagined as the sharp- ness of a point of a cone, where the light source is at the point and the cone represents the dispersion of light.

The three-dimensional angle of dispersion is measured in steradians. If a light source is at the center of a sphere that has a radius of 1 meter, and is illuminating one square meter of the surface of the sphere, the angle of dispersion is 1 steradian.

• A source of 1 lumen which projects all its light through a dispersion angle of 1 steradian is rated at 1 candela.

• The number of candelas does not define the angle of dispersion, only the intensity within that angle.

• A light source rated for 1,000 candelas could have a power of 10 lumens concentrated within an angle of 0.01 steradians, or could have a power of only 1 lumen concentrated within an angle of 0.001 steradians.

• There are 1,000 millicandelas in 1 candela. The abbreviation for candela is cd while the abbreviation for a millicandela is mcd.

• LEDs are often rated in mcd. The number de- scribes the intensity of light within its angle of dispersion.

MSCP

Although the term candlepower is obsolete, it has been redefined as being equal to 1 candela. Mean spherical candlepower (MSCP) is a measurement of all the light emitted from a lamp in all directions. Because the light is assumed to be omnidirectional, it fills 4 * π (about 12.57) steradians. Therefore 1 MSCP = approximately 12.57

lumens. In the United States, MSCP is still the most common method of rating the total light output of a miniature lamp.

Efficacy

The radiant luminous efficacy (abbreviated LER) assesses how effective a lamp is at channeling its output within the visible spectrum, instead of wasting it in other wavelengths, especially infra- red. LER is calculated by dividing the power emit- ted in the visible spectrum (the luminous flux) by the power emitted over all wavelengths.

Thus, if VP is the power emitted in the visible spectrum, and AP is the power emitted in all wavelengths:

LER = VP / AP

LER is expressed in lumens per watt. It can range from a low value of around 12 lm/W for a 40W incandescent bulb to 24 lm/W for a quartz halo- gen lamp. Fluorescent lamps may average 50 lm/ W. LEDs vary, but can achieve 100 lm/W.

Efficiency

The radiant luminous efficiency (abbreviated LFR) of a lamp measures how good its radiant luminous efficacy is, compared with an imaginary ideal lamp. (Note the difference between the words “efficiency” and “efficacy.”) LFR is deter- mined by dividing the radiant luminous efficacy (LER) by the maximum theoretical LER value of 683 lm/W, and multiplying by 100 to express the result as a percentage. Thus:

LFR = 100 * ( LER / 683 )

The LFR ranges from around 2% for a 40W bulb to 3.5% for a quartz halogen lamp. LEDs may be around 15% while fluorescents are closer to 10%.

How to Use It

When first introduced, LEDs were limited by their higher price, lower maximum light output, and inability to display blue or white. The price difference has disappeared for small indicators, while gaps in the color range have been filled

(although the color rendering index of LEDs is still inferior).

Brightness remains an advantage for large incandescents relative to LEDs, as they are more upwardly scalable. However, fluorescents and vapor lamps have an advantage for very high light output, as in the lighting of big-box stores or parking lots. Thus the range of applications for incandescent bulbs is diminishing, especially be- cause common types are now illegal for domes- tic light fixtures in many parts of the world.

Relative Advantages

When choosing whether to use an incandescent lamp or an LED, these advantages of an incandescent lamp should be considered:

• The intensity can be adjusted with a triacbased dimmer. Regular fluorescents cannot be dimmed, while LEDs often require different dimmer circuitry.

• The intensity can also be adjusted with a rheostat. The output from fluorescents can- not.

• Easy white-balance correction. LEDs and fluorescents do not naturally produce a consistent output over the visible spectrum.

• Can be designed to operate directly from a wide range of voltages (down to around 2V and up to around 300V). A higher voltage entails a longer filament wire, which may re- quire a larger bulb. LEDs require additional components and circuitry to use higher voltages.

• Incandescent bulbs are more tolerant of volt- age fluctuations than LEDs. With battery operation, the incandescent will still provide some reduced light output when the voltage has diminished radically. LEDs will not per- form at all at currents lower than their threshold.

• An incandescent is nonpolarized and may be socketed, which simplifies user replacement.

LEDs are polarized and are usually soldered in.

• Can be powered by AC or DC without any modification or additional circuitry. LEDs re- quire DC, which must be provided through a transformer and rectifier, or similar electronics, if AC power is the primary source.

• Can be equally visible from a wide range of viewing angles. LEDs have restricted viewing angles.

• The heat output from an incandescent bulb may occasionally be useful (for example in a terrarium, or in incubators for poultry).

• Trouble-free switching. Fluorescents tend to hesitate and blink when power is applied, and they require a ballast to energize them. The lifespan of fluorescents is reduced by frequent switching.

• No low-temperature problems. Incandescent lamps are not significantly affected by low temperatures. Fluorescents may not start easily in a cold environment, and may flicker or glow dimly for 10 minutes (or more) until they are warm enough to function properly.

• Easy disposal. Fluorescent lights contain small quantities of mercury that are an environmental hazard. They should not be mixed with ordinary trash. Compact fluorescent

although the lifetime of a small panel indicator can be equal to that of an LED if a low color temperature is acceptable.

• Requires a filter or tinted glass envelope to generate colored light. This further reduces the lamp’s efficiency.

• Cannot be miniaturized to the same degree as an LED indicator.

Derating

The lifespan of a lamp can be greatly extended by choosing one with a higher current rating or using it at a lower voltage. The light output will be reduced, and the color temperature will be at a lower Kelvin number, but in some situations this tradeoff may be acceptable.

The graphs in Figure 18-10 suggest that if the voltage of a hypothetical miniature lamp is reduced to 80% of the manufacturer’s recommended value, this can make the lamp last 20 times as long. Note, however, that this will cut the light intensity to 50% of its normal value.

Conversely, using 130% normal voltage will give 250% of the normal light output, while shortening the life of the lamp to 1/20 of its normal value. Naturally these figures are approximations that may not apply precisely to a specific lamp.

What Can Go Wrong

lamps (CFLs) and LEDs used for room lighting will be packaged with electronics that should ideally be recycled, although this is not very practical. Incandescent bulbs impose the least burden on the environment when they are thrown away.

However, the incandescent lamp has some obvious disadvantages:

• Relatively inefficient.

• More susceptible to vibration.

• Likely to have a shorter natural life expectancy than LEDs, fluorescents, or neon bulbs,

High Temperature Environment

If an incandescent lamp is used in an environment hotter than 100 degrees Celsius, the life of the lamp is likely to be reduced by the “water cycle.” Any water molecules inside the glass envelope will break down, allowing oxygen to com- bine with the tungsten filament to form tungsten oxide. The tungsten is deposited on the inside of the glass while the oxygen is liberated and be- gins a new cycle.

Figure 18-10. The life expectancy of a hypothetical miniature lamp is very strongly influenced by voltage. Applying only 60% of the rated voltage can make a lamp last 500 times its normal lifespan, although it will greatly reduce light output. Note that the vertical axes apply to curves of the same color. Adapted from “Characteristics of Miniature Lamps” from Toshiba Lighting and Technology Corporation.

Fire Risk

The partially evacuated bulb of an incandescent lamp provides some separation and protection from the heat in the filament, but if the bulb can- not disperse heat by radiation or convection, its temperature can rise to the point where it ignites flammable materials.

Halogen lamps have an elevated fire risk because they operate at a higher temperature and are smaller, providing less surface area to disperse the heat. They also contain gases under seven to eight atmospheres of pressure. Thermal stress can cause a halogen bulb to shatter, and finger- prints on the glass can increase this risk.

Current Inrush

When an incandescent lamp is first switched on, its filament has one-tenth the resistance that it will exhibit when it becomes hot. Consequently, the lamp will take a large initial surge of current, which stabilizes after about 50 milliseconds. This should be considered if one or more small lamps shares a DC power supply with components such as logic chips that may be sensitive to voltage fluctuations.

Replacement Problems

Because of the limited life of incandescent lamps, they should be installed in such a way that they are easy to replace. This can be an issue with panel indicators, where disassembly of a device may be necessary to reach the lamp.

The range of small incandescent lamps is diminishing, and may continue to diminish in the future. Future availability of replacement lamps should be considered when designing a circuit. When building equipment in small quantities, spare lamps should be purchased for future use.