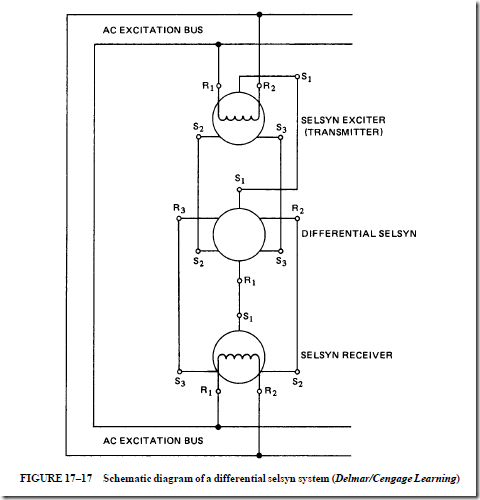

SELSYN DIFFERENTIAL SYSTEM

A selsyn differential system consists of a transmitter, a differential, and a receiver, Figure 17–17. The differential selsyn resembles a miniature wound-rotor induction motor. There are three rotor windings, usually connected in wye. The windings are brought out through three slip rings to external terminals R1, R2, and R3. The stator windings are also connected in wye. They are brought out to terminals S1, S2, and S3. The differential selsyn is really a single-phase transformer. Three-phase voltages and currents are not present.

The stator windings serve as the primary side. The rotor windings serve as the second- ary side. The differential selsyn is used to modify the electrical angle transmitted by the transmitter selsyn. This means that the selsyn receiver will take up a position that is either the sum or the difference of the angles applied to the selsyn transmitter and the differential selsyn. Thus, two selsyn generators (transmitters) can be connected through a differential selsyn and turned through any angle. The differential selsyn will indicate the difference between the two angles.

For the differential system shown in Figure 17–17, the voltage distribution in the pri- mary winding is the same as that in the secondary winding of the excited selsyn. If any one of the three selsyns is fixed in position, and a second selsyn is displaced by a certain angle, the third selsyn will turn through the same angle. The direction of rotation can be reversed by reversing any pair of leads to the rotor or stator windings of the differential selsyn. If any two of the selsyns are rotated at the same time, the third selsyn will rotate through an angle equal to the algebraic sum of the movement of the first two selsyns. The algebraic sign of the angle depends on the physical direction of rotation of the rotors and the phase rotation of the windings.

The differential selsyn is not connected directly to the excitation source. The excitation current for the differential must be furnished through one, or both, of the standard selsyn units. Generally the excitation current is supplied to the primary (stator) windings of the differential selsyn from the exciter selsyn. For this reason, the exciter selsyn is always designed to be larger in capacity than the selsyn transmitter or receiver.

SUMMARY

• The synchronous motor

1. It is a three-phase ac motor that operates at a constant speed from no load to full load.

2. It is similar to a three-phase generator.

3. It has a revolving field. This field is separately excited from a direct-current source, which can be varied to obtain a wide range of lagging and leading power factor values.

4. The synchronous motor is used in many industrial applications because

a. it has a fixed speed from no load to full load.

b. it has a high efficiency.

c. the initial cost is low.

d. it can improve the power factor of three-phase ac industrial circuits.

5. Construction

a. The three-phase synchronous motor consists of

(1) a laminated stator core with a three-phase armature winding.

(2) a revolving field with an amortisseur winding and slip rings.

(3) brushes and brush holders.

(4) two end shields that house the bearings supporting the rotor shaft.

b. The leads for the stator winding are marked T1, T2, and T3.

c. The field is marked F1 and F2.

6. Operating principles

b. A three-phase voltage applied to the stator windings causes a rotating mag- netic field.

(1) This field travels at the synchronous speed.

(2) The field cuts across the amortisseur (squirrel-cage) winding of the rotor.

(3) A magnetic field is set up in the rotor. This field reacts with the stator field and causes the rotation of the rotor.

(4) The rotor speed reached 95% to 97% of synchronous speed.

c. A synchronous motor is started by connecting its armature winding (stator) to the ac line and its field windings (rotor) to a field discharge resistor. The motor is started as an induction motor.

(1) The voltage induced in the field windings may reach 1500 V. Therefore, the field circuits must be well insulated and enclosed to protect personnel.

(2) The field discharge resistor is connected across the field windings so that the energy in the field circuit is spent in the resistor.

d. Once the motor accelerates to nearly 95% of synchronous speed

(1) the field circuit is energized from the dc source.

(2) the field discharge resistor is disconnected.

(3) the rotor pulls into synchronism with the revolving armature (stator) flux. Thus, the motor will operate at a constant speed.

e. To shut down the motor, the field circuit is deenergized by opening the field discharge switch. The field discharge resistor is connected across the field circuit to reduce the induced voltage in the field as the field flux collapses. The energy stored in the magnetic field is spent in the resistor, and a lower voltage is induced in the field circuit.

• Load on a synchronous motor

1. Once the rated load is applied, there is an angular displacement of the rotor pole with respect to the stator pole.

2. The speed is unchanged because the rotor continues to rotate at the synchronous speed.

3. The angular displacement between the centers of the stator and rotor field poles is called the torque angle and is represented by the Greek letter alpha, a.

a. At no load, the torque angle is nearly 0°.

b. As the mechanical load increases, the torque angle increases. The phase angle between the impressed voltage and the counter emf also increases. This increase means that the impressed voltage will cause more current in the sta- tor windings to meet the additional load demands.

c. A serious overload causes too large a value of the phase angle. In this case, the rotor pulls out of synchronism. With the aid of the amortisseur winding, the motor will operate as an induction motor.

d. The pullout torque is the maximum torque value that can be developed by a synchronous motor without dropping out of synchronism. The pullout torque is usually 150% to 200% of the rated torque output.

• Power factor of a synchronous motor

1. Changes in dc field excitation alter the power factor of a synchronous motor.

a. Increasing the resistance of the field rheostat lowers the field current. A poor lagging power factor results. As the field current decreases, more magnetizing current is supplied by the ac stator windings. This ac current lags the voltage by 90° and causes a low lagging power factor.

b. As the field current increases, the stator supplies a smaller magnetizing com- ponent of current. Thus, the power factor increases.

2. The field strength can be increased until the power factor is unity or 100%.

3. When the power factor reaches unity, the three-phase ac circuit supplies energy current only.

4. The amount of dc field excitation required to obtain a unity power factor is called the normal field excitation.

5. Overexciting the dc field produces a demagnetizing component of current called the quadrature lead current. The motor has a leading power factor.

• Industrial applications

1. Synchronous motors rated at 20 hp or more are used for constant-speed applications.

2. They are used to drive large air and gas compressors that are operated at fixed speeds to maintain a constant output at the maximum efficiency.

3. They are also used to drive dc generators, fans, blowers, and large pumps in water- pumping stations.

4. Three-phase synchronous motors can be used to drive mechanical loads and correct power factor values.

5. When the synchronous motor is used to correct the power factor only, it is called a synchronous capacitor or a synchronous condenser. It then has the same function as a bank of capacitors.

• Formulas for synchronous motors

• Generally, a synchronous motor is started at full voltage. Motors rated as high as 10,000 or 15,000 hp may be started at full voltage.

1. When the starting inrush current is high enough to cause voltage disturbances, reduced voltage starting current can be used.

2. Fifty percent to 65% of the rated line voltage is applied to the motor through a reactor or an autotransformer starter.

3. At a reduced voltage, the motor starts as an induction motor. It accelerates to a speed close to the synchronous speed. Then the autotransformer, or reactor starter, is shifted into the running position. At this point, the dc field circuit is energized.

• Nameplate data

1. The nameplate data for the synchronous motor is the same as that for an ac generator. A horsepower rating is given for the synchronous motor instead of a kVA rating.

2. The mechanical load, in horsepower output, and the electrical load, in leading kilovars, must not exceed the rating of the motor.

• Synchronous motor losses are the same as those for an ac generator.

• The efficiency of the three-phase synchronous motor is slightly higher than that of an induction motor having the same speed and horsepower ratings.

• Small single-phase synchronous motor

1. This type of motor is used in many applications, including electric clocks, time switches, graphical recording instruments, and stroboscope devices.

2. These motors do not require dc field excitation.

3. The Warren (or General Electric) clock motor is a commonly used motor of this type.

a. It consists of a laminated stator core with an exciting coil. Normally, this coil is wound for 120-V operation.

b. The coil has two poles, and each pole is divided into two sections. One turn of heavy copper wire is placed over half of each pole to produce a rotating field effect.

c. The rotor consists of several hardened steel discs that are pressed on the small rotor shaft. The rotating field acts on the rotor to produce a strong torque. The rotor accelerates to a speed near synchronous speed. It then locks into synchronism with the rotating field. The flux of the rotating field seeks the path of minimum reluctance (resistance) through the two small rotor crossbars.

4. The Holtz motor

a. This type of motor has the same shaded-pole arrangement as the Warren motor.

b. The rotor has six slots that hold a small squirrel-cage winding.

c. The motor starts as a squirrel-cage motor. The salient poles of the rotor then lock with the sections of the field poles twice each cycle. The resulting speed at 60 Hz is one-third of the synchronous speed, or 1200 r/min.

5. Selsyn motors

a. Selsyn is a contraction of the term self-synchronous.

b. Selsyn motors are used to interconnect two or more remote points of a system by electrical means.

c. A selsyn system indicates the positions of remote devices such as generator rheostats, steam turbine governors, waterwheel governors, transformer tap connections, swing gates or valves, elevators, and the roll height in steel roll- ing mills. Selsyn motors are also used in automatic control systems, signaling systems, and remote control systems.

d. The rotor terminals are marked R1 and R2. The stator terminals are marked S1, S2, and S3.

e. The rotor field circuit is excited from an external single-phase source.

f. The stator windings consist of a conventional three-phase winding.

g. One motor of a selsyn system is called the transmitter and the other motor is called the receiver.

(1) The stator terminals of one motor are wired to the stator terminals of the other motor in sequence.

(2) The rotors (R1 and R2 ) are tied together and are connected in common to an alternating-current source. Turning the rotor of one motor causes the rotor of the other motor to be displaced an equal amount.

6. Selsyn differential system

a. A differential unit is added between the transmitter and the receiver of the common selsyn system.

b. The differential resembles a miniature wound-rotor induction motor.

There are three rotor windings. Leads R1, R2 , and R3 are brought out through three slip rings. The stator windings are marked S1, S2, and S3.

c. The differential selsyn is used to modify the electrical angle transmitted by the transmitter selsyn. The differential selsyn indicates the sum or difference between the two selsyns.

Achievement Review

1. What are the factors that determine the speed of a synchronous motor?

2. Explain how the operation of a synchronous motor is different from that of a squirrel-cage induction motor.

3. What is the purpose of the amortisseur winding in a synchronous motor?

4. Explain how a synchronous motor adjusts its electrical input with an increase in the mechanical output.

5. What is the purpose of the field discharge resistor that is used with the separately excited dc field circuit of a synchronous motor?

6. A motor generator set is used for frequency conversion from 60 Hz to another frequency. A three-phase, 60-Hz synchronous motor with 24 poles is used as the prime mover. The ac generator has 20 poles.

a. Find the speed of the synchronous motor.

b. Find the frequency of the output voltage of the ac generator.

7. When is a synchronous motor underexcited? When is it overexcited?

8. Describe a method for starting a large three-phase synchronous motor.

9. A three-phase, three-wire, 208-V feeder supplies two motors. One motor is a three-phase, squirrel-cage induction motor and requires 50 A at 0.80 lagging power factor. The other motor is a three-phase synchronous motor that requires 40 A at a leading power factor of 0.75.

a. For the squirrel-cage induction motor, determine

(1) the apparent power, in kilovolt-amperes.

(2) the true power, in kilowatts.

(3) the reactive power, in kVARs.

b. For the three-phase synchronous motor, determine

(1) the apparent power, in kilovolt-amperes.

(2) the true power, in kilowatts.

(3) the reactive power, in kVARs.

10. For the circuit given in question 9, determine

a. the total true power, in kilowatts, supplied by the feeder circuit.

b. the total apparent power, in kVA, supplied by the feeder circuit.

c. the power factor of the feeder circuit. Indicate whether it is a leading or lag- ging power factor.

d. the quadrature power, in kVARs, supplied by the feeder circuit.

e. the total current, in amperes, supplied by the three-phase, three-wire feeder to operate both motors.

11. A three-phase, three-wire, 2400-V feeder supplies an industrial plant that has a 500-kVA load operating at a lagging power factor of 0.75. A 2400-V, three- phase synchronous motor is to be installed. This motor will require 200 kVA at a power factor of 0.80 lead. With the synchronous motor in operation, determine

a. the total load, in kW, on the 2400-V feeder.

b. the total load, in kVA, on the 2400-V feeder.

c. the power factor on the 2400-V feeder. Indicate whether it is a leading or lag- ging power factor.

12. What are some practical applications for three-phase synchronous motors?

13. Explain the operation of a General Electric (Warren) clock.

14. Explain the operation of a single-phase Holtz motor.

15. Draw a circuit diagram for a selsyn circuit consisting of a selsyn transmitter and a selsyn receiver.

16. Explain the operation of the selsyn circuit in question 15.

17. Draw a circuit diagram for a selsyn circuit, including a selsyn transmitter, a differential selsyn, and a selsyn receiver.

18. Explain the operation of the differential selsyn system in question 17.

19. List some practical uses for selsyn units.