STEPPING MOTORS

Stepping motors are devices that convert electrical impulses into mechanical movement. Stepping motors differ from other types of dc or ac motors in that their output shaft moves through a specific angular rotation each time the motor receives a pulse. Each time a pulse is received, the motor shaft moves by a precise amount. The stepping motor allows a load to be controlled with regard to speed, distance, or position. These motors are very accurate in their control performance. Generally, less than 5% error per angle of rotation exists, and this error is not cumulative regardless of the number of rotations. Stepping motors are operated on dc power but can be used as a two-phase synchronous motor when connected to ac power.

Theory of Operation

Stepping motors operate on the theory that like magnetic poles repel and unlike magnetic poles attract. Consider the circuit shown in Figure 18–39. In this illustration, the rotor is a permanent magnet and the stator winding consists of two electromagnets. If cur- rent flows through the winding of stator pole A in such a direction that it creates a north

magnetic pole, and through B in such a direction that it creates a south magnetic pole, it would be impossible to determine the direction of rotation. In this condition, the rotor could turn in either direction.

Now consider the circuit shown in Figure 18–40. In this circuit, the motor contains four stator poles instead of two. The direction of current flow through stator pole A is still in such a direction as to produce a north magnetic field; the current flow through pole B

produces a south magnetic field. The current flow through stator pole C, however, produces a south magnetic field, and the current flow through pole D produces a north magnetic field. As illustrated, there is no doubt regarding the direction or angle of rotation. In this example, the rotor shaft will turn 90° in a counterclockwise direction.

Figure 18–41 shows yet another condition. In this example, the current flow through poles A and C is in such a direction as to form a north magnetic pole, and the direction of current flow through poles B and D forms south magnetic poles. In this illustration, the permanent-magnet rotor has rotated to a position between the actual pole pieces.

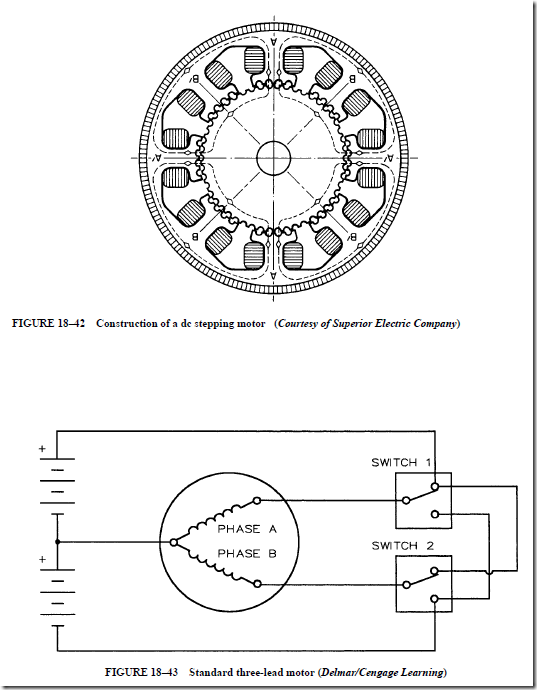

To allow for better stepping resolution, most stepping motors have eight stator poles, and the pole pieces and rotor have teeth machined into them as shown in Figure 18–42. In practice, the number of teeth machined in the stator and rotor determines the angular rotation achieved each time the motor is stepped. The stator–rotor tooth configuration shown in Figure 18–42 produces an angular rotation of 1.8° per step.

Winding

There are different methods for winding stepper motors. A standard three-lead motor is shown in Figure 18–43. The common terminal of the two windings is con-nected to ground of an aboveground–belowground power supply. Terminal 1 is connected to the common of a single-pole, double-throw switch (switch 1), and terminal 3 is connected to the common of another single-pole, double-throw switch (switch 2). One of the stationary contacts of each switch is connected to the positive or aboveground voltage,

and the other stationary contact is connected to the negative or belowground voltage. The polarity of each winding is determined by the position setting of its control switch.

Stepping motors can also be wound bifilar, as shown in Figure 18–44. The term bifilar means that there are two windings wound together. This is similar to a transformer winding with a center-tap lead. A bifilar stepping motor has twice as many windings as does the three-lead type, which makes it necessary to use smaller wire in the windings. This results in higher wire resistance in the winding, producing a better inductive–resistive (L/R) time constant for the bifilar wound motor. The increased L/R time constant results in better motor performance. The use of a bifilar stepper motor also simplifies the drive circuitry requirements. Notice that the bifilar motor does not require an aboveground–belowground power supply. As a general rule, the power supply voltage should be about five times greater than the motor voltage. A current-limiting resistance is used in the common lead of the motor. This current-limiting resistor also helps improve the L/R time constant.

Four-Step Switching (Full Stepping)

The switching arrangement shown in Figure 18–44 can be used for a four-step sequence. Each time one of the switches changes position, the rotor will advance one-fourth of a tooth. After four steps, the rotor has turned the angular rotation of one “full” tooth. If the rotor and stator have 50 teeth, it will require 200 steps for the motor to rotate one full revolution. This corresponds to an angular rotation of 1.8° per step (360°/200 steps 1.8° per step). Figure 18–45 illustrates the switch positions for each step.

Eight-Step Switching (Half-Stepping)

Figure 18–46 illustrates the connections for an eight-stepping sequence. In this arrangement, the center-tap lead for phases A and B are connected through their own separate current-limiting resistors back to the negative of the power supply. This circuit contains four separate single-pole switches instead of two switches. The advantage of this arrangement is that each step causes the motor to rotate one-eighth of a tooth instead of one-fourth of a tooth. The motor now requires 400 steps to produce one revolution, which

produces an angular rotation of 0.9° per step. This results in better stepping resolution and greater speed capability. The chart in Figure 18–47 illustrates the switch position for each step. Figure 18–48 depicts a solid-state switching circuit for an eight-step switching arrangement. A stepping motor is shown in Figure 18–49.

AC Operation

Stepping motors can be operated on ac voltage. In this mode of operation, they become two-phase ac synchronous constant-speed motors and are classified as permanent-magnet induction motors. Refer to the exploded diagram of a stepping motor in Figure 18–50. Notice that this motor has no brushes, slip rings, commutator, gears, or belts. Bearings maintain a constant airgap between the permanent-magnet rotor and the stator windings. A typical eight-stator pole-stepping motor will have a synchronous speed of 72 r/min when connected to a 60-Hz two-phase ac power line.

A resistive–capacitive network can be used to provide the 90° phase shift needed to change single-phase ac into two-phase ac. A simple forward–off–reverse switch can be added to provide directional control. A sample circuit of this type is shown in Figure 18–51. The correct values of resistance and capacitance are necessary for proper opera- tion. Incorrect values can result in random direction of rotation when the motor is started, change of direction when the load is varied, and erratic and unstable operation, as well as failure of the motor to start. The correct values of resistance and capacitance will be different with different stepping motors. The manufacturer’s recommendations should be followed for the particular type of stepping motor used.

Motor Characteristics

When stepping motors are used as two-phase synchronous motors, they have the ability to virtually start, stop, or reverse direction of rotation instantly. The motor will start within about 11⁄2 cycles of the applied voltage and stop within 5 to 25 ms. The motor can maintain a stalled condition without harm to it. Because the rotor is a permanent magnet, no induced current is in the rotor, and no high inrush of current occurs when the motor is started. The starting and running currents are the same. This simplifies the power requirements of the circuit used to supply the motor. Because of the permanent- magnet structure of the rotor, the motor does provide holding torque when turned off. If more holding torque is needed, dc voltage can be applied to one or both windings when the motor is turned off. An example circuit of this type is shown in Figure 18–52. If dc voltage is applied to one winding, the holding torque will be approximately 20% greater than the rated torque of the motor. If dc voltage is applied to both windings, the holding torque will be about 11⁄2 times greater than the rated torque.

SUMMARY

• Types of single-phase motors (split-phase)

1. Single-phase induction motor

2. Repulsion motor

3. Repulsion-induction motor

4. Series motor (universal motor)

5. Shaded-pole motor

• Three-phase motors generally perform better than do single-phase motors. In many instances, however, only single-phase service is available.

• Most single-phase motors have fractional horsepower ratings. In general, their use is limited to commercial and residential applications.

• Resistance-start, induction-run motor

1. A resistance-start, induction-run motor has the following basic parts:

a. A stator (stationary part).

b. A rotor (revolving part).

c. A centrifugal switch, located inside the motor.

d. Two end shields bolted to the steel frame; these shields house the rotor shaft bearings.

e. A cast steel frame; the stator core is pressed into this frame.

2. The stator contains two windings, which are placed 90 electrical degrees apart.

a. The main or running winding

b. The starting or auxiliary winding

3. At start-up, both windings are connected in parallel to the single-phase line. Once the motor accelerates to two-thirds or three-quarters of the rated speed, a centrifugal switch disconnects the starting winding automatically.

4. The rotor of the resistance-start, induction-run motor is the same as that of a three- phase, squirrel-cage induction motor.

a. The rotor contains no windings, brushes, slip rings, or commutator where faults may develop.

b. Fans are provided with the rotor to keep the temperature of the windings at a reasonable level.

5. The centrifugal switch is mounted inside the motor. It disconnects the starting winding after the rotor reaches approximately 66% to 75% of its rated speed.

6. The running winding has a low resistance and a high inductive reactance. Thus, the current of the running winding lags behind the voltage.

7. The current in the starting winding is more nearly in phase with the voltage because the winding has a high resistance and a low inductive reactance.

8. When a current passes through each of these windings, the resulting pulsating field effect gives rise to a rotating field around the inside of the stator core.

9. While traveling at the synchronous speed, S 120 f /P, the rotating field cuts the copper bars of the squirrel-cage winding (rotor). Voltages are induced in the winding and cause currents in the rotor bars.

10. A rotor field is created. This field reacts with the stator field to develop the torque that causes the rotor to turn.

11. As the rotor nears the rated speed, the centrifugal switch disconnects the start- ing winding from the line. The motor then continues to operate, using only the running winding and the current induced in the rotor. The alternating voltages produced generate a torque that keeps the rotor turning.

12. The motor resembles a two-phase induction motor because the currents of the windings are approximately 90 electrical degrees out of phase with each other. However, a single-phase source supplies the motor. Therefore, the motor is called a split-phase motor.

13. If the motor does not start, but a low humming sound is present, then one wind- ing is open. The centrifugal switch should be checked to determine whether its mechanism is faulty or whether the switch contacts are pitted.

14. If the motor operates on its starting winding for more than 60 seconds, the winding may char or burn out.

15. To reverse the rotation of the motor, interchange the leads of either the starting winding or the running winding (preferably the starting winding). Interchanging these leads reverses the direction of rotation of the field.

16. Dual-voltage motors

a. Some single-phase motors have dual-voltage ratings such as 115/230 V. The running winding consists of two sections, each of which is rated at 115 V.

b. The windings are marked “T1 and T2” and “T3 and T4 .”

c. For the higher voltage, the two windings are connected in series across 230 V.

d. For the lower voltage, the windings are connected in parallel across 115 V.

e. The starting winding consists of one winding rated at 115 V.

f. It is connected in parallel across 115 V with the two running windings.

g. For the higher voltage, the starting winding is connected in parallel across one of the series running windings.

17. Speed regulation

a. A resistance-start, induction-run motor has very good speed regulation from no load to full load.

b. The regulation compares to that of a three-phase, squirrel-cage induction motor.

c. The percent slip ranges from 4% to 6%.

18. Starting torque

a. The starting torque of the motor is poor.

b. A phase angle of 30° to 50° is large enough to provide a weak rotating mag- netic field and the starting torque is small.

• Capacitor-start, induction-run motor

1. This type of motor is similar to the resistance-start, induction-run motor. A capacitor is connected in series with the starting winding. The capacitor is mounted in or on the motor.

2. The starting torque is higher than that of a resistance-start motor.

3. The capacitor limits the starting surge of current to a lower value as compared to the resistance-start motor.

4. This motor is used in refrigeration units, compressors, oil burners, small-machine equipment, and any application where split-phase induction motors are used.

5. The basic operation of this motor is nearly the same as that of the resistance-start, induction-run motor. The capacitor is energized for two or three seconds only at start-up. Thus, it cannot improve the power factor.

6. Defective capacitors often cause problems in the motors using them.

a. The capacitor may short-circuit and blow the fuse on the branch motor circuit.

b. If the fuse rating is high, and the fuse does not interrupt the power supply to the motor, the starting winding may burn out.

• Multispeed motors

1. Two basic types of motors are used for multispeed applications:

a. The consequent pole motor.

b. The capacitor-start, capacitor-run motor.

2. The consequent pole motor changes speed by changing the number of stator poles. This causes the synchronous speed of the rotating magnetic field to change.

3. The capacitor-start, capacitor-run (CSCR) type of multispeed motor changes speed by inserting impedance in series with the run winding.

4. Multispeed motors commonly have from two to five ranges of speed.

5. Capacitor-start, capacitor-run motors designed for use as multispeed motors have higher impedance windings than other CSCR motors.

• Repulsion-type motors

1. There are three types of repulsion motors:

a. The repulsion motor

b. The repulsion-start, induction-run motor

c. The repulsion-induction motor

2. These three types of motors differ in their construction, operating characteristics, and industrial applications.

a. Repulsion motor

(1) The stator is usually wound with four, six, or eight poles.

(2) The rotor is a slotted core containing a winding. The rotor is similar to the armature of a dc motor. The coils are connected to the commutator through segments, or bars, parallel to the armature shaft.

(3) Carbon brushes contact the commutator surface. The brush holders are movable. They are connected together by heavy copper jumpers. The brushes are movable so that they can make contact at different points to obtain the correct rotation and maximum torque output.

(4) To reverse the motor, the brushes are shifted 15 electrical degrees to the other side of the stator field pole centers.

(5) This motor has excellent starting torque.

(6) The speed of the motor can be changed by changing the value of the supply voltage.

(7) The motor has very unstable speed characteristics. It may race to a very high speed if there is no mechanical load.

b. Repulsion-start, induction-run motor

(1) This motor is available in two basic types: the brush-lifting motor and the brush-riding motor.

(2) For the brush-lifting motor, a centrifugal device lifts the brushes from the commutator surface at 75% of the rated speed. A short-circuiting necklace shorts out the commutator. The brushes are lifted from the commutator, thus saving wear and tear on all parts.

(3) The brush-riding type of motor has the same short-circuiting neck- lace, but the brushes ride on the commutator at all times.

(4) This motor starts like a repulsion motor. After it reaches 75% of the rated speed, it runs as an induction motor.

(5) To reverse the direction of rotation, follow the steps outlined for a repul- sion motor.

(6) These motors may be designed for dual-voltage connections.

c. Repulsion-induction motor

(1) This type of motor has the same characteristics as a repulsion-start, induction-run motor. It does not have a centrifugal mechanism.

(2) It does have a squirrel-cage winding beneath the slots of the armature.

The squirrel-cage winding improves the speed regulation from no load to full load.

(3) The speed for this type of motor is similar to that of the dc compound motor.

(4) The motor may be designed for dual-voltage windings.

• The same schematic diagram symbol is used for the repulsion-induction motor, the repulsion motor, and the repulsion-start, induction-run motor.

• The dc series or shunt motor cannot be operated from an ac supply.

• Universal motor

1. The field poles of a universal motor are laminated to reduce eddy currents.

2. The voltage loss across the field poles is reduced by using a small number of field turns on a low-reluctance core.

3. A universal motor can be operated on an ac or dc supply.

4. Universal motors are available with fractional horsepower ratings and are commonly used in household appliances.

5. The field windings and the armature of a universal motor are connected in series.

6. There are two versions of the universal distributed field motor: the two-field motor and the single-field compensated motor. The two-field motor has a main winding and a compensating winding to reduce the reactance voltage developed in the armature by the alternating flux.

7. The speed of a universal motor can be controlled by varying the inductance through taps on one of the field poles. The motor may be operated at an excessive speed with no load. Universal motors are permanently connected to the devices being driven.

8. To reverse the direction of rotation, the current flow is reversed through the field circuit or the armature circuit.

• Conductive and inductive compensation

1. Conductive compensation is achieved by placing special windings in slots cut in the pole faces to overcome the armature reaction under load.

a. The strength of this field increases with an increase in the load current.

b. The compensating winding is connected in series with the series field winding and the armature.

c. A motor with conductive compensation has high starting torque and poor speed regulation.

2. An inductively coupled winding is also used to overcome armature reaction in ac series motors.

a. This winding acts like a short-circuited secondary winding in a transformer.

b. The operating characteristics of an inductively compensated motor are similar to those of the conductively compensated motor.

• Shaded-pole induction motor

1. Small fractional horsepower induction motors may be started by shading coils mounted on each of the stator poles.

2. A standard squirrel-cage rotor is used.

3. The motor does not require a starter mechanism such as a centrifugal switch.

4. The shading coil is a low-resistance copper loop.

5. The shading poles distort the main flux pattern, and therefore set up a rotating magnetic field.

6. The torque produced is small.

7. Shaded poles are used only on motors rated at 1⁄10 hp or smaller.

8. A shaded-pole motor is used in applications where a strong torque is not needed, such as for fans and blowers.

• Variable-speed motors

1. Two types of motors are used for variable-speed control:

a. The capacitor-start, capacitor-run motor

b. The shaded-pole induction motor

2. These motors are generally used because they do not require the use of a centrifugal switch.

3. Motors used for variable-speed control have higher impedance windings than do other types of motors not designed for use as variable-speed motors.

4. There are two general methods used to control the speed of variable-speed motors:

a. Variable-voltage control

b. Inserting impedance in series with the motor winding

5. Two common methods of obtaining variable voltage are

a. A solid-state controller using a triac

b. An autotransformer

6. Only triac controllers designed for use as variable-speed motor controllers should be used.

• Stepping motors

1. Stepping motors generally operate on direct current and are used to produce angular movements in steps.

2. Stepping motors are generally used for position control.

3. Stepping motors can be used as single-phase synchronous motors when connected to two-phase ac.

4. Most stepping motors operate at a synchronous speed of 72 r/min when connected to 60-Hz ac.

5. Stepping motors can produce a holding torque by applying a continuous direct current to their stator windings.

6. Full stepping produces an angular rotation of 1.8° per step for a total of 200 steps per revolution.

7. Half stepping produces an angular rotation of 0.9° per step for a total of 400 steps per revolution.

Achievement Review

1. Explain how a motor is started using the split-phase method.

2. Explain why the starting torque of a capacitor-start, induction-run motor is better than that of a resistance-start, induction-run motor.

3. How is the direction of rotation reversed for each of the following?

a. Resistance-start, induction run motor

b. Capacitor-start, induction-run motor

4. The centrifugal switch contacts fail to close when a resistance-start, induction-run motor is deenergized. Explain what happens when the motor is energized.

5. A resistance-start, induction-run motor is started with a heavy overload. The motor fails to accelerate to a speed high enough to open the centrifugal switch contacts. What will happen?

6. A resistance-start, induction-run motor has a dual-voltage rating of 120/240 V. This motor has two running windings, each rated at 120 V, and one starting wind- ing rated at 120 V. Draw a schematic connection diagram for this motor connected for 240 V.

7. Show the connections for a 120-V, capacitor-start, induction-run motor.

8. a. Compare the operating characteristics of a resistance-start, induction-run motor with those of a capacitor-start, induction-run motor.

b. List three applications for

(1) a resistance-start, induction-run motor.

(2) a capacitor-start, induction run motor.

9. Explain the differences in construction and operation between a capacitor-start, induction-run motor and a capacitor-start, capacitor-run motor.

10. Explain how a repulsion motor operates.

11. a. Explain why torque is not developed by a repulsion motor when the brushes are placed directly in line with the stator pole centers.

b. The brushes are shifted 90 electrical degrees from the position described in part a of this question. Is a torque developed by the motor in this case?

c. At what position should the brushes be placed relative to the stator pole centers to obtain the maximum torque?

12. Explain how a repulsion-start, induction-run motor operates.

13. Explain the difference between a repulsion-start, induction-run motor (brush-lift- ing type) and a repulsion-start, induction-run motor (brush-riding type).

14. How are the following motors reversed?

a. A repulsion motor

b. A repulsion-start, induction-run motor

15. Compare the operating characteristics of a repulsion motor with those of a repulsion- start, induction-run motor.

16. List three practical applications for

a. a repulsion motor.

b. a repulsion-start, induction-run motor.

17. Explain the difference between a repulsion-start, induction-run motor and a repulsion- induction motor.

18. Explain why shunt motors cannot be operated satisfactorily on ac service.

19. What is the difference between an ac series motor and a dc series motor?

20. Why are ac series motors with small fractional horsepower ratings called

universal motors?

21. What is the difference between a series motor with conductive compensation and a series motor with inductive compensation?

22. List four practical applications for ac series motors.

23. Describe the construction and operation of a shaded-pole motor.

24. Where is the shaded-pole motor used?

25. A 120-V, two-pole, 60-Hz, capacitor-start, induction-run motor has a full-load speed of 3450 r/min. Determine

a. the synchronous speed.

b. the percent slip.

26. Name two methods of changing the speed of the rotating magnetic field.

27. What type of multispeed motor changes speed by changing the synchronous speed of the rotating magnetic field?

28. Name a major difference between capacitor-start, capacitor-run motors designed for multispeed use and CSCR motors that are not.

29. What two types of motors are used as variable-speed motors?

30. Why are these types of motors used?

31. Name two methods of controlling the speed of variable-speed motors.

32. What solid-state component is used to control the voltage applied to a variable- speed motor?

33. Explain the difference in operation between a stepping motor and a common dc motor.

34. What is the principle of operation of a stepping motor?

35. Why do stepping motors have teeth machined into the stator poles and rotor?

36. When a stepping motor is connected to ac power, how many phases must be applied to the motor?

37. How many degrees out of phase are the voltages of a two-phase system?

38. What is the synchronous speed of an eight-pole stepping motor when connected to a two-phase, 60-Hz ac line?

39. How can the holding torque of a stepping motor be increased?