REPULSION-TYPE MOTORS

There are three general types of repulsion motors: the repulsion motor; the repulsion- start, induction-run motor; and the repulsion-induction motor. These three types of motors differ in their construction, operating characteristics, and industrial applications.

REPULSION MOTOR

Construction

A repulsion motor has the following basic components:

1. A laminated stator core; one winding of the stator is similar to the main (running) winding of a split-phase motor. The stator is usually wound with four, six, or eight poles.

2. A rotor consisting of a slotted core containing a winding. This rotor is called an armature because it is similar to the armature of a dc motor. The coils of this armature winding are connected to the commutator. The axial-type commutator has segments, or bars, parallel to the armature shaft.

3. Two cast steel end shields that act as protection for the motor bearings. These bear- ings are mounted on the motor frame.

4. Carbon brushes that contact with the commutator surface. A brush holder assembly, mounted on one of the end shields, holds the brushes in place. The brushes are con- nected together by heavy copper jumpers. The brush holder assembly can be moved. In this way, the brushes can contact the commutator at different points to obtain the correct rotation and maximum torque output.

5. Two bearings that support and center the armature shaft in the stator core. Either sleeve bearings or ball bearings may be used.

6. A cast steel frame; the stator core is pressed into this frame.

Operation of a Repulsion Motor

When the stator winding is connected to a single-phase line, a field is set up by the current in the windings. A voltage and a resultant current are induced in the rotor windings by this field. By placing the brushes in the proper position on the commutator segments, the current induced in the armature windings causes magnetic poles in the armature. These poles have a set relationship to the stator field poles.

The armature field poles are displaced by 15 electrical degrees from the field poles of the stator windings. Because the instantaneous polarity of the rotor poles is the same as that of the adjacent stator poles, a repulsion torque is formed. This torque causes the motor armature to rotate. This motor is known as a repulsion motor because it is based on the principle that like poles repel.

Positioning the Brushes. Figure 18–20, parts A–D, shows how the positioning of the brushes affects the torque. In Figure 18–20A, there is no torque when the brushes are placed at right angles to the stator poles. In this position, there are equal induced voltages in the two halves of the armature winding. These voltages oppose each other at the connection between the two sets of brushes. Therefore, there is no current in the windings, and no flux is set up by the armature windings.

In Figure 18–20B, the brushes are now under the center of the stator poles. In this position, there is a heavy current in the armature windings. However, a torque is not created. The armature poles due to the current are in line with the stator poles. Thus, there is no twisting force (torque) in either the clockwise or counterclockwise direction.

Figure 18–20C shows the brushes shifted in a counterclockwise direction from the stator pole centers by 15 electrical degrees. The magnetic poles set up in the armature are 15 electrical degrees from the stator pole centers and have the same polarity. Thus, a repulsion torque is formed between the stator and rotor field poles. This torque causes the armature to rotate counterclockwise.

To reverse the motor, the brushes are shifted 15 electrical degrees to the other side of the stator field pole centers (Figure 18–20D). The armature poles formed again have the same polarity but are now 15° in a clockwise direction from the stator pole centers. This torque causes the armature to rotate clockwise.

Torque and Speed. The repulsion motor has excellent starting torque. The speed of this motor can be varied by changing the value of the supply voltage. However, the repulsion motor has unstable speed characteristics. It may race to a very high speed if there is no mechanical load. The repulsion motor can be used for applications requiring a strong starting torque and a range of speed control.

REPULSION-START, INDUCTION-RUN MOTOR

There are two basic types of repulsion-start, induction-run motors. For the brush- lifting type of motor, the brushes lift off the commutator surface once the motor accelerates to nearly 75% of the rated speed. The second type of motor is known as the brush-riding type. In this motor, the brushes ride on the commutator surface at all times.

Construction

A repulsion-start, induction-run motor has the following components:

1. A laminated stator core. This core has one winding that is similar to the running winding of a split-phase motor.

2. A rotor consisting of a slotted core. The core contains a winding that is connected to a commutator. The rotor core and winding are similar to the armature of a dc motor. Thus, the rotor is called an armature.

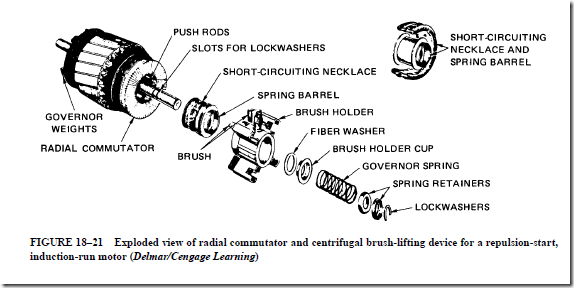

3. a. For the brush-lifting motor, a centrifugal device lifts the brushes from the commutator surface at 75% of the rated speed. The centrifugal mechanism consists of governor weights, a short-circuiting necklace, spring barrel, spring, push rods, brush holders, and brushes.

b. For the brush-riding motor, a centrifugal device also operates at 75% of the rated speed. This mechanism consists of governor weights, a short-circuiting neck- lace, and a spring barrel. The centrifugal device short-circuits the commutator segments but does not lift the brushes and brush holders from the commutator surface.

4. A special radial-type commutator is used in the brush-lifting motor. The brush-riding motor has an axial-type commutator.

5. a. The brush holder assembly for the brush-riding motor is the same as the one used on a repulsion motor.

b. The brush holder assembly for the brush-lifting motor is designed so that the centrifugal device can lift the brush holders and the brushes from the commutator surface.

6. The end shields, bearings, and motor frame are the same as those used in the repulsion motor.

Operation

A repulsion-start, induction-run motor and a repulsion motor are started in the same way. The repulsion-start, induction-run motor, however, operates as an induction motor once it accelerates to 75% of the rated speed.

Figure 18–21 is an exploded view of an armature, radial commutator, and centrifugal device used on the brush-lifting motor.

Operation of the Centrifugal Mechanism. As the push rods of the centrifugal mechanism move forward, they push the spring barrel forward. The short-circuiting necklace then contacts the bars of the radial commutator and all of the bars are short-circuited. At the same time, the brush holders and brushes are lifted from the commutator surface. In this way, there is no unnecessary wear on the brushes and the commutator surface. Lifting the brushes from the commutator also eliminates a great deal of noise.

By short-circuiting the commutator bars, the armature is converted to a form of squirrel-cage rotor. As a result, the motor operates as a single-phase induction motor. This type of motor starts as a repulsion motor and runs as an induction motor.

Brush-Riding Motor. The brush-riding type of motor uses an axial commutator. The centrifugal mechanism consists of a number of copper segments held in place by a spring (Figure 18–22). This device is mounted next to the commutator. At nearly 75% of the rated speed, centrifugal force causes the short-circuiting necklace to short-circuit the commuta- tor segments. When this happens, the motor operates as an induction motor.

Torque and Speed. The starting torque and speed performances are very good for both types of repulsion-start, induction-run motors. Therefore, these motors are suitable for applications requiring a strong starting torque and a fairly constant speed from no load to full load. Typical uses include commercial refrigerators, compressors, and pumps.

To reverse the direction of rotation of the repulsion-start, induction-run motor, follow the steps outlined for a repulsion motor.

Schematic Diagrams. A schematic diagram of a repulsion-start, induction-run motor is shown in Figure 18–23. The same diagram also represents a repulsion motor.

Repulsion-start, induction-run motors are often constructed for operation on either 120 or 240 V. That is, two stator windings are provided. For 120-V operation, the wind- ings are connected in parallel. For 240-V operation, the windings are connected in series.

A schematic diagram is given in Figure 18–24 for a dual-voltage, repulsion-start, induction-run motor. The connection table provided shows how the leads of this motor are connected for 120- or 240-V operation. The same connections also apply to dual-voltage repulsion motors.

REPULSION–INDUCTION MOTOR

A repulsion-induction motor has nearly the same operating characteristics as a repulsion-start, induction-run motor. However, this type of motor has no centrifugal mechanism. The repulsion-induction motor has the same type of armature and commutator as the repulsion motor, but it does not have a centrifugal mechanism. There is a squirrel-cage winding beneath the slots of the armature of the repulsion-induction motor, as shown in Figure 18–25.

Both the repulsion-induction, motor and the repulsion-start, induction-run motor have very good starting torque because they start as repulsion motors. The squirrel-case winding of the repulsion-induction motor means that it has fairly constant speed regulation from no load to full load. The start-up of this motor and that of the repulsion-start, induction-run motor are similar. This motor is called a repulsion-induction motor to distinguish it from the repulsion-start, induction-run motor having a centrifugal system.

The torque–speed performance of a repulsion-induction motor is similar to that of a dc compound motor.

The repulsion-induction motor is designed for use on 120 or 240 V. The stator wind- ings have two sections that are connected in parallel for 120-V operation and in series for 240-V operation. The markings of the motor terminals and the connection arrangement

for these leads are the same as for a repulsion-start, induction-run motor. The repulsion- induction motor, the repulsion motor, and the repulsion-start, induction-run motor all have the same schematic diagram symbol.

ALTERNATING-CURRENT SERIES MOTOR

Without careful examination, it may appear that the typical dc series or shunt motor can be operated from an ac supply. If the line terminals to the dc motor are reversed, the current and the magnetic flux are reversed in both the field and armature circuits. For a motor operating from an ac source, the net torque will be in the same direction. As a result, it is impractical to operate a dc shunt motor in this manner because the high inductance of the shunt field causes the field current and the field flux to lag the line voltage by almost 90°. The motor thus develops little torque.

Universal Motors

Another reason why the series dc motor should not be operated on ac is the large amount of heat due to eddy currents in the field poles. In addition, there is an excessive voltage drop across the series field windings due to the high reactance. The field poles may be laminated to reduce the eddy currents. The voltage loss across the field poles can be reduced by using a small number of field turns on a low reluctance core. The core is then operated at a low flux density. This type of motor is known as a universal motor and can operate on ac or dc. Universal motors are available with fractional horsepower ratings and are commonly used in household appliances.

A concentrated field universal motor has two salient poles and a winding of few turns connected to give the opposite magnetic polarity. Figure 18–26 shows the laminated field structure of a typical concentrated field universal motor.

The field windings and armature of a universal motor are connected in series, as shown in Figure 18–27.

Universal Motor Type

Another type of universal motor is the distributed field motor. One version of this motor is a single-field compensated motor. A second version is a two-field compensated motor. The field windings of a two-pole, single-field compensated motor resemble the sta- tor winding of a two-pole, split-phase ac motor. A two-field compensated motor has a stator with a main winding and a compensating winding. These windings are spaced 90 electrical degrees apart. When the motor is operated from an ac source, the compensating winding reduces the reactance voltage developed in the armature by the alternating flux.

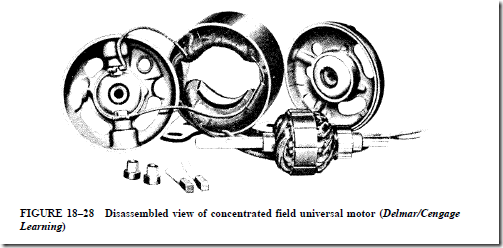

Universal motors have aluminum, cast iron, and rolled steel frames (Figure 18–28). The field poles are bolted to the frame. The field cores consist of laminations bolted together. The armature core is also laminated. A conventional commutator and brushes are used.

Speed Control

Universal motors operate at nearly the same speed on dc and single-phase ac. These series-wound motors operate at excessive speeds with no load. To overcome this, they are

permanently connected to the devices being driven. The speed regulation for universal motors consists of resistance inserted in series with the motor. Tapped resistors, rheostats and tapped nichrome wire coils, wound over a single-field pole, are used. The speed can also be controlled by varying the inductance through taps on one of the field poles.

Motor Reversal

Any series-wound motor can be reversed by changing the direction of the current in either the field or armature circuit. Universal motors are sensitive to brush position. Severe arcing at the brushes results when the direction of rotation is changed and the brushes are not shifted to the neutral (sparkless) plane.