21–4 FIELD DISTORTION AND THE NEED FOR INTERPOLES

In our study of generators we learned of a concept known as armature reaction (Section 19–4), which results in a distortion of the magnetic field. This distortion causes the neutral plane to shift forward (with respect to the direction of rotation).

In electric motors, as in generators, the current of the armature produces a magnetic field that interacts with and distorts the magnetic field in which the armature rotates. However, the magnetic action of motors is opposite to that of generators and, consequently, the neutral plane is shifted backward with respect to the direction of rotation; see Figure 21–9.

To counteract this warping of the magnetic field, large DC motors are often built with interpoles, or commutating poles. The windings of these poles are in series with the armature. The poles produce a field that counteracts the armature field. Interpoles increase efficiency and control excessive sparking at the commutator when the motor is operated under conditions requiring high armature current. In the motor shown in Figure 21–10, the four large poles are the main field poles, and the four small ones are the interpoles.

In a motor, the interpoles must have the same polarity as the main poles directly in back of them (back in the sense of direction of rotation of the armature); see Figure 21–11. In a generator, the interpoles have the same polarity as the main poles directly ahead of them.

In Figure 21–10, assuming a clockwise rotation of the armature (not shown), the polarities of the four main field poles and their interpoles would be as indicated.

DC machines are generally designed in such a manner that they can be employed as either a generator or a motor. Since the polarity of the interpoles differs between a genera- tor and a motor, many manufacturers provide access to the interpole winding by bringing leads out to the terminal connection box. Interpole, or commutating field, leads are generally labeled C1 and C2. Since the commutating field is connected in series with the armature, some manufacturers label the leads S3 and S4.

21–5 THE SHUNT MOTOR

DC motors, like DC generators, are classified by the way their field coils are connected; thus, we differentiate between shunt motors, series motors, and compound motors.

Shunt motors, as their name implies, have their field coils connected in parallel to their armature and the power supply, as shown in Figure 21–12. The shunt field, therefore, consists of many turns of fine wire and maintains a steady magnetic field as long as the line voltage is constant. The torque of the motor is therefore solely a function of the armature current.

Let us assume that the load on a motor is increased. As a result, the motor slows down. Consequently, the cemf goes down also, the armature current increases, and the motor increases its torque to meet the new demand of the load.

This action can be summarized by a form of shorthand notation, in which arrows pointing up indicate an increase of the quantity and vice versa, like this:

Speed Regulation

When the torque increases to meet the new load demand, the speed will readjust itself; thus, the motor maintains a fairly constant speed. We say that the motor is self-regulating. This self-regulating effect, called speed regulation, is a characteristic of the motor itself. The speed regulation is numerically expressed as

Note: The concept of speed regulation is not just for shunt motors but applies to all types of electric motors. The lower the percentage of regulation, the more constant the speed of the motor.

In a DC motor, the speed regulation is proportional to the resistance of the armature. The lower the armature resistance, the better speed regulation the motor will exhibit. DC motors operate on the principle of attraction and repulsion of magnetism between the magnetic field developed in the pole pieces and the magnetic field developed in the armature. If load is added to the motor, the motor must produce more torque to overcome the added load. To produce more torque, the magnetic field strength of the armature or pole pieces must increase. The increase in field strength is accomplished when the armature speed decreases, causing less counter-emf to be produced in the armature. The decrease of cemf permits more current to flow through the armature, causing an increase in magnetic field strength. The amount of counter-emf produced in the armature is proportional to the magnetic field strength of the pole pieces and the speed of armature rotation. If the armature resistance is very low, a small decrease of cemf will cause a significant increase in current and magnetic field strength.

EXAMPLE 21–3

Given: A motor turns 1,620 rpm at rated load but speeds up to 1,750 rpm when the load is removed.

Find: The speed regulation.

The concept of regulation allows us to compare the speed change characteristic of various motors. A low-percentage regulation indicates a fairly constant speed. Example 21–3 is typical of shunt motors, which makes this type of motor desirable for industrial applications with constant speed requirements.

Shunt motors have a peculiar characteristic. When resistance is added to their shunt field circuits, thereby decreasing the current and the magnetic flux, the motors will speed up. (This feature is explained in greater detail later in this chapter.) This fact must be understood to appreciate that shunt motors, especially the large ones, must be protected against an accidental loss of their magnetic field. If, for some reason, the shunt field should open up, the loss of the magnetic field would cause the motor to accelerate to dangerously high levels.

If you wonder how a motor can run without a magnetic field, remember that there is a sufficient amount of residual magnetism to cause the motor to run away. Runaway motors can eventually destroy themselves due to the physical stress caused by centrifugal force.

Note: Study groups desiring a more detailed analysis of shunt-motor characteristics are referred to the Appendix.

21–6 THE SERIES MOTOR

Unlike the shunt-motor field in which magnetization is attained by a small current in many turns, the series-motor field carries the entire current in a low-resistance coil of few turns; see Figure 21–13. Shunt field magnetization remains constant whether or not armature current changes; series field magnetization changes as the motor changes under varying load.

Unlike the shunt motor, the series motor does not have a constant speed characteristic. With every change in load, the current through the field coil changes correspondingly, causing tremendous speed variations.

Unlike in the shunt motor, the torque and speed of the series motor are inversely proportional. In our accepted shorthand notation, this can be expressed as

In other words, whenever the load on a series motor is reduced, the motor will speed up. In fact, if the load should be completely disconnected, the series motor might run away and destroy itself.

One might reason that the brisk acceleration would cause the cemf to increase rap- idly enough to shut off the torque-producing current. This, however, is not possible due to the sharp decrease in the magnetic flux. Thus, the torque accelerates the motor further, theoretically without limit. With the load removed, speeds can easily rise to 10,000 rpm, and if the friction in the motor is less than equivalent to the torque produced, speeds build up even more.

In actuality, the top speed of series motors is limited.

• In small motors, friction from bearings, brushes, and windage limits the speed. At 10,000 rpm, the entire power input can be expended on friction, and there is no further increase in speed.

• In large motors, high speed produces inertial forces that burst the bands holding the armature coils in place. At 5,000 rpm, the surface of an 8-inch-diameter armature is traveling at about 2 miles per minute, and each ounce of copper wire in the slots requires a force of 180 pounds to hold it in place.

For these reasons, it is recommended that series motors be used only in applications where the load is geared directly to the shaft of the motor. Belt drives, which are prone to slip or break, are not suitable for use with series motors.

A motor with such severe limitations must have some other strong advantages to recommend itself, and, indeed, it does. The series motor has the ability to provide high levels of torque at startup or whenever a sudden overload condition places a heavy demand on the motor. Let us see why this is so.

Torque is an interaction of the two fields produced by the armature and the series field. Let us assume the current through the motor is doubled. This, in turn, doubles the magnetic flux of the series field as well as the magnetic flux of the armature. As a result, the torque will increase by a factor of (2)2, or 4. We say that the torque of the series motor is proportional to the square of the current. (Of course, this statement is made with the assumption that the magnetic core is not saturated. Nevertheless, it should make the point that the series motor is ideally suited for any industrial application where extremely high torque is required and where very heavy overload is suddenly applied during operation. Examples of such applications include cranes, hoists, electric loco- motives for railways, and other electrical vehicles.)

But remember that this type of motor cannot be used where a relatively constant speed is required from no load to full load. Because the series motor has poor speed regulation, it can reach a dangerously fast speed when the load is removed.

Note: Study groups desiring a more detailed analysis of series-motor characteristics are referred to the Appendix.

Compare the advantages of series and shunt motors. The shunt motor has a more constant speed, but the series motor (of the same power rating) can exert a much greater torque without a great increase in current. These two desirable features can be obtained in the same motor by placing both a series field winding and a shunt field winding on the field poles of the motor, which is now a compound motor.

Consider the effect of adding a few series field turns to an existing shunt motor. At heavy loads, when the motor slows down, the increased current through the series field boosts the field strength, which gives added torque and speed.

Or consider the effect of adding a shunt field to a series motor. At light loads, when the motor tends to overspeed because of decreased field flux, the added constant-flux shunt field provides enough flux to put a reasonable limit on the top speed.

Combining the two fields within one motor results in a machine that retains the excellent starting torque of the series motor without the excessive speedup when the load is removed. These beneficial characteristics are derived only when the two field coils, the shunt and the series coils, produce magnetic fields aligned in the same direction (Figure 21–14). Wound in this manner, the windings are aiding each other in producing flux, and the motor is called a cumulative compound motor; see Figure 21–14. Most compound motors are wound in this manner and, therefore, the term compound motor implies that it is cumulatively compounded.

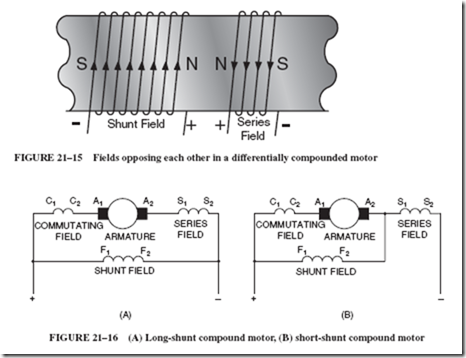

Infrequently, a motor is connected with its series field opposing the shunt field; in other words, their magnetic fields are opposing each other. This can be done either by winding the two coils in different directions on the field pole, as shown in Figure 21–15, or simply by reversing the current through one set of coils, arranged as in Figure 21–14. This type of motor is said to be differentially compounded.

When the shunt field is connected directly to the line, the connection is called long shunt, as shown in Figure 21–16A. When the shunt field is connected directly across the armature, the connection is called short shunt; see Figure 21–16B. The long-shunt connection is generally used, but the type of connection makes no particular difference in motor performace.

If a given long-shunt motor is reconnected to a short shunt, slight changes do occur. At no load, with small armature current, the shunt field current passing through

the series field slightly increases the total field flux. As a result, the maximum rpm of the motor is reduced. At heavy overload with high armature current, the voltage drop on the series field reduces voltage and current available to the shunt field. As a result, to maintain a high torque, the motor can take 1% more current and run 1% faster than when connected long shunt.

Excellent speed regulation can be obtained with this type of motor. The motor runs with practically constant speed under varying load conditions.

In summary, compound motors are generally connected long shunt and cumulative compound. Such motors develop a high torque when the load is suddenly increased. This motor also has another advantage: It does not race to an excessively high speed if the load is removed.

Some of the industrial applications for this motor are drives for passenger and freight elevators, for metal stamping presses, for rolling mills in the steel industry, for metal shears, and in similar applications.

The graphs in Figure 21–17 compare the characteristics of the three types of motors: series, shunt, and cumulative compound. Compound motors can be built with characteristics approaching either the series or the shunt characteristics, depending on the relative division of ampere-turns between series and shunt coils.