SUMMARY

This topic has presented information on miniature and microminiature (2M) repair procedures and 2M safety precautions. The information that follows summarizes the important points of this topic.

CONFORMAL COATINGS are protective materials applied to electronic assemblies to prevent damage caused by corrosion, moisture, and stress.

CONFORMAL COATINGS REMOVAL is accomplished mechanically, chemically, or thermally, depending on the material used.

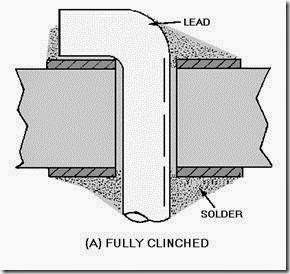

Component LEADS are terminated either through the board, above the board, or on the board.

SOLDER may be removed by wicking, by a manual vacuum plunger, or by a continuous vacuum solder extractor.

SOLDER may be removed by wicking, by a manual vacuum plunger, or by a continuous vacuum solder extractor.

ELECTRONIC ASSEMBLIES should be restored to the original manufacturer’s standards using the same orientation and termination method.

A GOOD SOLDER JOINT is bright and shiny with no cracks or pits.

When REPLACING DIPs, TOs, AND FLAT PACKS, make certain that pins are placed in the proper position.

COMPONENT LEADS may be clipped prior to removal only if the part is known to be bad or if normal removal will result in board damage.

The technician must determine through INSPECTION what method of repair is necessary for the board.

ELECTROSTATIC DISCHARGE (ESD) can damage or destroy many types of electronic components including integrated circuits and discrete components.

ELECTROSTATIC DISCHARGE (ESD) can damage or destroy many types of electronic components including integrated circuits and discrete components.

Special handling is required for ELECTROSTATIC-DISCHARGE-SENSITIVE (ESDS) devices or components.

USE PRESCRIBED SAFETY PRECAUTIONS when you use power tools, soldering irons, cleaning solvents, and aerosol dispensers.

ANSWERS TO QUESTIONS Q1. THROUGH Q36.

A1. Conformal coating.

A2. Chemical, mechanical, and thermal.

A3. Solvents or xylene and trichloroethane.

A4. Mechanical.

A5. To ensure protective characteristics are maintained.

A6. Interfacial connections.

A7. Clinched lead, straight-through, and offset pad.

A8. Above-the-board termination.

A9. On-the-board termination.

A10. During disassembly or repair.

A11. Wicking.

A12. Continuous vacuum.

A13. These methods should not be used.

A14. Manufacturer’s standards.

A15. A fine abrasive.

A16. 90 degrees.

A17. They should be readable from a single point.

A18. In the direction of the run.

A19. The ease with which molten solder wets the surfaces of the metals to be joined.

A20. Conductive-type soldering iron.

A21. The type of work to be done.

A22. A thermal shunt.

A23. Bright and shiny with no cracks or pits.

A24. If the component is known to be defective or if the board may be damaged by normal desoldering.

A25. By pushing it gently out of the board.

A26. Heat each lead and lift with tweezers.

A27. Use a skipping pattern.

A28. Inspect and test.

A29. Operational failures, repairs by untrained personnel, repair using improper tools, mishandling, improper shipping, packaging, and storage.

A30. Clinched staple.

A31. Epoxy a replacement pad to the board, set an eyelet, and solder it.

A32. Repairs by untrained personnel and technicians using improper tools.

A33. Epoxy and fiberglass powder.

A34. Esd, improper stowage, and improper handling.

A35. To discharge any static charge built up in the body.

A36. Deviation from prescribed safe operating procedures.