TWO-ELEMENT WATTMETER FOR THREE-PHASE SYSTEM

Unit 10 described power measurement in three-phase circuit systems. Recall that two single-phase wattmeters were used to measure the power in a three-phase, three-wire sys- tem. The two single-phase wattmeters can be combined into a single instrument. The scale of this instrument indicates the sum or difference of the power values indicated by the separate meters. To make the single wattmeter, two sets of potential coils are mounted on a single shaft. Also, two sets of field coils are mounted on the instrument frame so that they have the proper relationship to the armature coils. In this way, each of two power measuring mechanisms develops a torque that is proportional to the power in the circuit to which it is connected. These torque values are added to obtain the total power in the three-phase, three-wire circuit.

If the power factor of the system is less than 0.5, the torque of one mechanism opposes that of the second mechanism. The difference between the torque values is the power indication.

A wattmeter containing two dynamometer mechanisms (Figure 11–15) is called a two-element wattmeter.

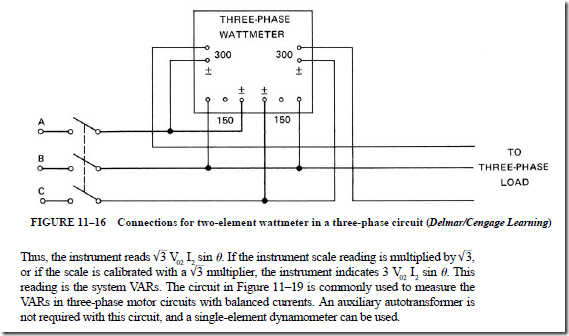

In Figure 11–16, a two-element wattmeter is shown connected into a three-phase circuit. The current and potential terminals are shown on the instrument case for both elements. Note that the connections shown in Figures 11–15 and 11–16 are the same as the connections given for the two-wattmeter method described in Unit 10.

VARMETERS

The previous section showed how the dynamometer-type mechanism is used to mea- sure true power in watts. This same instrument can also be used to measure the reactive volt-amperes (VARs) in an ac circuit. In this use, the instrument is known as a varmeter. The wattmeter indicates the product of the circuit voltage and the in-phase component of the current. The varmeter indicates the product of the circuit voltage and the current component 90° out of phase with the voltage.

To measure VARs, the phase of the potential coil voltage must be shifted by 90°. The flux of the potential coil is then in phase with the flux due to the quadrature component of current in the stationary coil. The phase shift in a single-phase circuit is obtained by connecting an external impedance in series with the potential coil. In this way, the current in the movable coils lags the voltage by 90°.

Measurement of VARs in a Three-Phase Circuit

To find the VARs in a three-phase circuit, a two-element varmeter is used. This device has the same construction as a two-element wattmeter. However, as shown in Figure 11–17, an external phase-shifting autotransformer is added to the varmeter to shift the potential coil voltages 90 electrical degrees.

In Figures 11–17 and 11–18, voltages 1–2 and 3–2 are applied to the transformer from the three-phase line. Taps on the autotransformer are selected as follows:

POWER FACTOR METERS

The power factor of a circuit can be determined by taking simultaneous readings with a wattmeter, an ammeter, and a voltmeter. However, this method is too inconvenient to be used when the power factor of a system is to be determined repeatedly. The task is

simplified by the use of a power factor meter. Any deflection of the meter pointer indicates the ratio of the power in watts to the apparent power in volt-amperes. The instrument also shows whether the current is lagging, or leading, the voltage.

Single-Phase Power Factor Meter

A single-phase power factor meter resembles a single-phase wattmeter. The stationary field coils are connected in series with one side of the line. The field coils carry the line current and produce the field flux. The single-phase power factor meter differs from the wattmeter in that it has no control springs. The moving coil, or armature construction, is also different in the power factor meter. The moving mechanism has two armature coils. These coils are mounted on the same shaft. The axes of the coils are 90° apart. One moving coil is connected across the line with a noninductive resistance in series. The flux of this coil reacts with that of the field coil to produce a torque that is proportional to the in-phase component of current. The other moving coil is connected across the line and has an inductive reactance in series with it. The current in this coil lags the line voltage by almost 90°. Thus, the torque for this coil is proportional to the line current component, which is 90° out of phase with the line voltage.

Crossed-Coil Power Factor Meter

A schematic diagram of a single-phase power factor meter is shown in Figure 11–20. This meter is called a crossed-coil power factor meter because the two moving coils are crossed at a 90° angle. A cutaway view of the mechanism of a crossed-coil power factor meter is shown in Figure 11–21.

When this type of meter is connected into a circuit containing a noninductive unity power factor load, the entire line current is in phase with the voltage. This means that full torque is developed by the moving coil. The voltage of this coil is in phase with the line current. The quadrature component of current at unity power factor is zero. Thus, torque is not developed by the moving coil whose current lags the line voltage by 90°. As a result, the mechanism moves to a position where the flux alignment between the field current and the active moving coil is at a maximum. The pointer then indicates a power factor of unity, or 1.00.

Assume that the meter shown in Figure 11–21 is connected to a circuit having a power factor less than unity. The movable coil is in series with the inductive reactance. This coil develops torque in a direction determined by the lagging or leading quadrature current

component in the fixed field coils. The torque magnitude is determined by the amount of quadrature current. A torque is also created by the in-phase component of current opposing the torque caused by the quadrature current. The resultant of these two torques determines the final position of the pointer. As a result, control springs are not required. The pointer position shows the lagging or leading power factor value.

Another form of the crossed-coil power factor meter is shown in Figure 11–22. In this meter, separate elements are used for the in-phase current and the quadrature potential current.

The crossed-coil power factor meter designed for three-phase service is similar in appearance and structure to the single-phase meter. However, the operating principle of the three-phase meter is different. In the three-phase meter, the crossed coils of the moving mechanism are connected in series with resistors across two phases. The connections are made so that the torques of the two coils oppose each other. The stationary field coil (current coil) is connected in series with one phase leg. The two potential coils are energized from two phases common to the line wire in which the field coil or current coil is connected.

Figure 11–23 is a schematic diagram of the connections for a three-phase, crossed-coil power factor meter. The potential coils are placed at an angle of 60° with each other. For a balanced load, power factor variations change the phase angle between the field coil cur- rent and the two potential coil currents. Thus, one phase angle increases and the other angle decreases. Therefore, the torque of one part of the element is proportional to the cosine of 30°, plus the circuit phase angle. The torque of the other part of the element is the cosine of 30°, minus the circuit phase angle. The deflection shown by the meter actually varies by the ratio of the readings that would be given by separate single-phase wattmeters connected in corresponding phases. This ratio can be calibrated directly as the power factor.