SHUNT MOTOR

A shunt motor is connected in the same way as a shunt generator. The field windings are connected in parallel (shunt) with the armature windings. The circuit for a shunt motor is shown in figure 2-4.

Figure 2-4. – Shunt-wound dc motor.

Once you adjust the speed of a dc shunt motor, the speed remains relatively constant even under changing load conditions. One reason for this is that the field flux remains constant. A constant voltage across the field makes the field independent of variations in the armature circuit. If the load on the motor is increased, the motor tends to slow down. When this happens, the counter emf generated in the armature decreases. This causes a corresponding decrease in the opposition to battery current flow through the armature. Armature current increases, causing the motor to speed up. The conditions that established the original speed are reestablished, and the original speed is maintained.

Conversely, if the motor load is decreased, the motor tends to increase speed; counter emf increases, armature current decreases, and the speed decreases. In each case, all of this happens so rapidly that any actual change in speed is slight.

There is instantaneous tendency to change rather than a large fluctuation in speed.

Q.9 What advantage does a shunt motor have over a series motor?

COMPOUND MOTOR

A compound motor has two field windings, as shown in figure 2-5. One is a shunt field connected in parallel with the armature; the other is a series field that is connected in series with the armature.

The shunt field gives this type of motor the constant speed advantage of a regular shunt motor. The series field gives it the advantage of being able to develop a large torque when the motor is started under a heavy load. It should not be a surprise that the compound motor has both shunt- and series-motor characteristics.

Figure 2-5. – Compound-wound dc motor.

When the shunt field is connected in parallel with the series field and armature, it is called a "long shunt" as shown in figure 2-5, (view A). Otherwise, it is called a "short shunt", as shown in figure 2-5, (view B).

TYPES OF ARMATURES

As with dc generators, dc motors can be constructed using one of two types of armatures. A brief review of the Gramme-ring and drum-wound armatures is necessary to emphasize the similarities between dc generators and dc motors.

GRAMME-RING ARMATURE

The Gramme-ring armature is constructed by winding an insulated wire around a soft-iron ring (fig. 2-6). Eight equally spaced connections are made to the winding. Each of these is connected to a commutator segment. The brushes touch only the top and bottom segments.

There are two parallel paths for current to follow – one up the left side and one up the right side. These paths are completed through the top brush back to the positive lead of the battery.

Figure 2-6. – Gramme-ring armature.

To check the direction of rotation of this armature, you should use the right-hand rule for motors. Hold your thumb, forefinger, and middle finger at right angles. Point your forefinger in the direction of field flux; in this case, from left to right. Now turn your wrist so that your middle finger points in the direction that the current flows in the winding on the outside of the ring. Note that current flows into the page (away from you) in the left-hand windings and out of the page (toward you) in the right-hand windings. Your thumb now points in the direction that the winding will move.

The Gramme-ring armature is seldom used in modem dc motors. The windings on the inside of the ring are shielded from magnetic flux, which causes this type of armature to be inefficient. The Gramme-ring armature is discussed primarily to help you better understand the drum-wound armature.

DRUM-WOUND ARMATURE

The drum-wound armature is generally used in ac motors. It is identical to the drum winding discussed in the chapter on dc generators.

If the drum-wound armature were cut in half, an end view at the cut would resemble the drawing in figure 2-7, (view A),Figure 2-7, (view B) is a side view of the armature and pole pieces. Notice that the length of each conductor is positioned parallel to the

faces of the pole pieces. Therefore, each conductor of the armature can cut the maximum flux of the motor field. The inefficiency of the Gramme-ring armature is overcome by this positioning.

Figure 2-7. – Drum-type armature.

The direction of current flow is marked in each conductor in figure 2-7, (view A) as though the armature were turning in a magnetic field. The dots show that current is flowing toward you on the left side, and the crosses show that the current is flowing away from you on the right side.

Strips of insulation are inserted in the slots to keep windings in place when the armature spins. These are shown as wedges in figure 2-7, (view A).

Q.10 Why is the Gramme-ring armature not more widely used?

Q.11 How is the disadvantage of the Gramme-ring armature overcome in the drum-wound armature?

Back

Home

Up

Next

DIRECTION OF ROTATION

The direction of rotation of a dc motor depends on the direction of the magnetic field and the direction of current flow in the armature. If either the direction of the field or the direction of current flow through the armature is reversed, the rotation of the motor will reverse. However, if both of these factors are reversed at the same time, the motor will continue rotating in the same direction. In actual practice, the field excitation voltage is reversed in order to reverse motor direction.

Ordinarily, a motor is set up to do a particular job that requires a fixed direction of rotation. However, there are times when it is necessary to change the direction of rotation, such as a drive motor for a gun turret or missile launcher. Each of these must be able to move in both directions.

Remember, the connections of either the armature or the field must be reversed, but not both. In such applications, the proper connections are brought out to a reversing switch.

Q.12 In a dc motor that must be able to rotate in both directions, how is the direction changed?

MOTOR SPEED

A motor whose speed can be controlled is called a variable-speed motor; dc motors are variable-speed motors. The speed of a dc motor is changed by changing the current in the field or by changing the current in the armature.

When the field current is decreased, the field flux is reduced, and the counter emf decreases. This permits more armature current. Therefore, the motor speeds up. When the field current is increased, the field flux is increased.

More counter emf is developed, which opposes the armature current. The armature current then decreases, and the motor slows down.

When the voltage applied to the armature is decreased, the armature current is decreased, and the motor again slows down. When the armature voltage and current are both increased, the motor speeds up.

In a shunt motor, speed is usually controlled by a rheostat connected in series with the

field windings, as shown in figure 2-8. When the resistance of the rheostat is increased, the current through the field winding is decreased. The decreased flux momentarily decreases the counter emf. The motor then speeds up, and the increase in counter emf keeps the armature current the same. In a similar manner, a decrease in rheostat resistance increases the current flow through the field windings and causes the motor to slow down.

Figure 2-8. – Controlling motor speed.

In a series motor, the rheostat speed control may be connected either in parallel or in series with the armature windings. In either case, moving the rheostat in a direction that lowers the voltage across the armature lowers the current through the armature and slows the motor. Moving the rheostat in a direction that increases the voltage and current through the armature increases motor speed.

Q.13 What is the effect on motor speed if the field current is increased?

Back

Home

Up

Next

ARMATURE REACTION

You will remember that the subject of armature reaction was covered in the previous chapter on dc generators. The reasons for armature reaction and the methods of compensating for its effects are basically the same for dc motors as for dc generators.

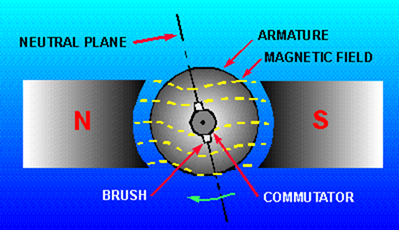

Figure 2-9 reiterates for you the distorting effect that the armature field has on the flux between the pole pieces. Notice, however, that the effect has shifted the neutral plane backward, against the direction of rotation. This is different from a dc generator, where the neutral plane shifted forward in the direction of rotation.

Figure 2-9. – Armature reaction.

As before, the brushes must be shifted to the new neutral plane. As shown in figure 2-9, the shift is counterclockwise. Again, the proper location is reached when there is no sparking from the brushes.

Q.14 Armature reaction in a dc motor causes a shift of the neutral plane in which direction?

Compensating windings and interpoles, two more "old" subjects, cancel armature reaction in dc motors. Shifting brushes reduces sparking, but it also makes the field less effective. Canceling armature reaction eliminates the need to shift brushes in the first place.

Compensating windings and interpoles are as important in motors as they are in generators. Compensating windings are relatively expensive; therefore, most large dc motors depend on interpoles to correct armature reaction. Compensating windings are the same in motors as they are in generators. Interpoles, however, are slightly different. The difference is that in a generator the interpole has the same polarity as the main pole AHEAD of it in the direction of rotation.

In a motor the interpole has the same polarity as the main pole FOLLOWING it.

The interpole coil in a motor is connected to carry the armature current the same as in a generator. As the load varies, the interpole flux varies, and commutation is automatically corrected as the load changes. It is not necessary to shift the brushes when there is an increase or decrease in load.

The brushes are located on the no-load neutral plane. They remain in that position for all conditions of load.

Q.15 What current flows in the interpole windings?

ARMATURE REACTION

You will remember that the subject of armature reaction was covered in the previous chapter on dc generators. The reasons for armature reaction and the methods of compensating for its effects are basically the same for dc motors as for dc generators.

Figure 2-9 reiterates for you the distorting effect that the armature field has on the flux between the pole pieces. Notice, however, that the effect has shifted the neutral plane backward, against the direction of rotation. This is different from a dc generator, where the neutral plane shifted forward in the direction of rotation.

Figure 2-9. – Armature reaction.

As before, the brushes must be shifted to the new neutral plane. As shown in figure 2-9, the shift is counterclockwise. Again, the proper location is reached when there is no sparking from the brushes.

Q.14 Armature reaction in a dc motor causes a shift of the neutral plane in which direction?

Compensating windings and interpoles, two more "old" subjects, cancel armature reaction in dc motors. Shifting brushes reduces sparking, but it also makes the field less effective. Canceling armature reaction eliminates the need to shift brushes in the first place.

Compensating windings and interpoles are as important in motors as they are in generators. Compensating windings are relatively expensive; therefore, most large dc motors depend on interpoles to correct armature reaction. Compensating windings are the same in motors as they are in generators. Interpoles, however, are slightly different. The difference is that in a generator the interpole has the same polarity as the main pole AHEAD of it in the direction of rotation.

In a motor the interpole has the same polarity as the main pole FOLLOWING it.

The interpole coil in a motor is connected to carry the armature current the same as in a generator. As the load varies, the interpole flux varies, and commutation is automatically corrected as the load changes. It is not necessary to shift the brushes when there is an increase or decrease in load.

The brushes are located on the no-load neutral plane. They remain in that position for all conditions of load.

Q.15 What current flows in the interpole windings?

Back

Home

Up

Next

The dc motor is reversed by reversing the direction of the current in the armature. When the armature current is reversed, the current through the interpole is also reversed. Therefore, the interpole still has the proper polarity to provide automatic commutation.

MANUAL AND AUTOMATIC STARTERS

Because the dc resistance of most motor armatures is low (0.05 to 0.5 ohm), and because the counter emf does not exist until the armature begins to turn, it is necessary to use an external starting resistance in series with the armature of a dc motor to keep the initial armature current to a safe value. As the armature begins to turn, counter emf increases; and, since the counter emf opposes the applied voltage, the armature current is reduced.

The external resistance in series with the armature is decreased or eliminated as the motor comes up to normal speed and full voltage is applied across the armature.

Controlling the starting resistance in a dc motor is accomplished either manually, by an operator, or by any of several automatic devices. The automatic devices are usually just switches controlled by motor speed sensors. Automatic starters are not covered in detail in this module.

Q.16 What is the purpose of starting resistors?

Back

Home

Up

Next

SUMMARY

This chapter presented the operating principles and characteristics of direct-current motors. The following information provides a summary of the main subjects for review.

The main PRINCIPLE OF A DC MOTOR is that current flow through the armature coil causes the armature to act as a magnet. The armature poles are attracted to field poles of opposite polarity, causing the armature to rotate.

The CONSTRUCTION of a dc motor is almost identical to that of a dc generator, both physically and electrically. In fact, most dc generators can be made to act as dc motors, and vice versa.

COMMUTATION IN A DC MOTOR is the process of reversing armature current at the moment when unlike poles of the armature and field are facing each other, thereby reversing the polarity of the armature field. Like poles of the armature and field then repel each other, causing armature rotation to continue.

COUNTER-ELECTROMOTIVE FORCE is generated in a dc motor as armature coils cut the field flux. This emf opposes the applied voltage, and limits the flow of armature current.

In SERIES MOTORS, the field windings are connected in series with the armature coil. The field strength varies with changes in armature current. When its speed is reduced by a load, the series motor develops greater torque. Its starting torque is greater than other types of dc motors. Its speed varies widely between full-load and no-load. Unloaded operation of large machines is dangerous.

In SHUNT MOTORS, the field windings are connected in parallel (shunt) across the armature coil. The field strength is independent of the armature current. Shunt-motor speed varies only slightly with changes in load, and the starting torque is less than that of other types of dc motors.

In COMPOUND MOTORS, one set of field windings is connected in series with the armature, and one set is connected in parallel. The speed and torque characteristics are a combination of the desirable characteristics of both series and shunt motors.

LOAD on a motor is the physical object to be moved by the motor.

DC MOTOR ARMATURES are of two types. They are the Gramme-ring and the drum-wound types.

THE GRAMME-RING ARMATURE is inefficient since part of each armature coil is prevented from cutting flux lines. Gramme-ring wound armatures are seldom used for this reason.

THE DRUM-WOUND ARMATURE consists of coils actually wound around the armature core so that all coil surfaces are exposed to the magnetic field. Nearly all dc motors have drum-wound armatures.

MOTOR REVERSAL in a dc motor can be accomplished by reversing the field connections or by reversing the armature connections. If both are reversed, rotation will continue in the original direction.

SPEED CONTROL IN A DC MOTOR is maintained by varying the resistance either in series with the field coil or in series with the armature coil. Increasing shunt-field circuit resistance increases motor speed. Increasing the armature circuit resistance decreases motor speed.

ARMATURE REACTION is the distortion of the main field in a motor by the armature field. This causes the neutral plane to be shifted in the direction opposite to that of armature rotation. Interpoles and compensating windings are used to reduce the effect of armature reaction on motor operation.

STARTING RESISTORS are necessary since the dc resistance of a motor armature is very low. Excessive current will flow when dc voltage is first applied unless current is limited in some way. Adding resistance in series with the armature windings reduces initial current. It may then be removed after counter emf has been built up.

Back

Home

Up

Next