Pipework and oil traps

Installation principles

The design and correct installation of the system pipework contributes to the reliability of the equipment, irrespective of the type. Design problems seldom occur with packaged systems because they would be overcome during development, but attention must be paid to other systems.

When a large installation is programmed, a site survey is usually carried out. This is intended to plan pipework routes, the method of installing and the components necessary to ensure a trouble-free installation, and to foresee any snags which might lead to costly modifications afterwards. In many instances the installation of small systems is left to the discretion of the installing engineer.

A reliable system must take into account the following:

1 The condensing unit should be mounted on a level and solid foundation.

2 Accessibility to all components for service and maintenance should be ensured.

3 Tubing runs between the evaporator and the condensing unit should be made as straight as possible and by the shortest route.

4 Excessive pressure drop should be avoided.

5 Where possible, depending upon the method of fixing, suction and liquid lines should be run together to produce an effective heat exchange.

6 Oil traps must be provided to ensure adequate oil return to the compressor.

7 Pipework must be firmly supported.

8 Where pipework passes through walls, floors and ceilings suitable sleeves should be provided. When routed at floor level, pipework should be protected.

9 The structure upon which the pipework is to be installed should be examined carefully.

10 Flexible couplings should be provided where necessary.

It is not intended to cover the finer details of installation practice.

Pipework fittings

Although it is general practice to install pipework where possible with brazed joints, flare fittings are still used. These should be kept to a minimum because too many in a circuit will create a pressure drop.

Flare unions and service and shut-off valve connections do not determine the diameter of the system pipework. It may be necessary to change a flare union to eliminate a pressure drop across a component.

A common cause of failure is the partial or complete loss of the refrigerant charge resulting from the use of an incorrect flare nut. A frostproof flare nut, for example, should be used on suction lines where extreme temperature changes can take place, i.e. frost on the suction line melting during an off cycle and freezing when the unit restarts. It is possible for ice to form between the long shoulder of a standard flare nut and the tubing; expansion of the ice and contraction of the tubing eventually fractures the flare (see Figure 66).

When a frostproof type is used on the high side of the system, vibration from gas pulsations at the compressor discharge or from an evaporator fan, plus the weight of the expansion valve, can cause the flare to rupture. The long shoulder

of the standard flare nut can prevent this by virtue of the reinforcement it provides, restricting lateral movement of the tubing and flare.

A vibration loop formed in a liquid line or in the small diameter tubing of a control line can have a twofold advantage. It will protect the flare against vibration, and may allow easy reforming of the tubing when a valve or control has to be changed (see Figure 67).

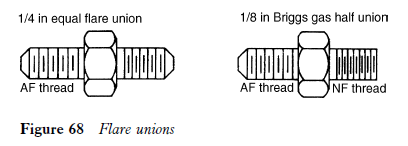

The leak potential is also increased when a flare union is used instead of a half union for connecting control lines to compressors or components. A half union does not have the seat facility of a flare union, although in some instances the threads may be the same. The difference is depicted in Figure 68.

Pipework supports

Currently three types of supports are used: the tubing saddle for smaller diameter tubing; a more elaborate assembly such as Hydra-zorb for larger diameter tubing; and the Munsen ring for iron and steel pipework, which obviously requires a stronger type of support structure (Figure 69).

Pipework must be well supported. For soft drawn copper tubing, the number of saddles used will depend upon the length of tubing run. For long runs the suction and liquid lines should be supported at intervals not exceeding 30 suction line tube diameters.

Hydra-zorb is ideal for larger hard drawn copper tubing and multiple installations. It consists of a metal wall mounted channel into which resilient tube mounting blocks and clamps are inserted.

The Munsen ring is basically a split clamp, which is usually cemented into the wall.

Soft drawn copper tubing supported by saddles brings both suction and liquid lines into close proximity. The tubing can be easily formed to touch and make thermal contact, thus creating heat exchange. The effect is to subcool the liquid refrigerant passing to the expansion valve and superheat the vapour returning to the compressor, which improves the system efficiency.

The other two types of support do not allow this heat exchange. Therefore for those types the tubing should be insulated where there is a possibility of frost or condensation forming.

The other two types of support do not allow this heat exchange. Therefore for those types the tubing should be insulated where there is a possibility of frost or condensation forming.

Isolating valves and controls should be installed in the pipework so as to provide easy access for maintenance or replacement.

Pipework should not obstruct the view of the crankcase oil sight glass. It should also be routed to avoid motor compressor end plates and terminal covers, and the drive belts and motors of open-type units.

Pipework should not obstruct the view of the crankcase oil sight glass. It should also be routed to avoid motor compressor end plates and terminal covers, and the drive belts and motors of open-type units.

When compressors are resiliently mounted it is advisable to install a flex- ible coupling (vibration eliminator) between the compressor and the pipework to compensate for movement when the compressor stops or starts. This is common with hermetic and semi-hermetic motor compressors. With open- type units this may not be necessary, but if a flexible coupling is used it should be installed parallel to the compressor drive shaft. These couplings are illustrated in Figure 70.

Pipework routes

When condensing units or remote condensers are located above the level of a coldroom, it is possible that the pipework will pass through a wooden floor. The pipework will be subject to variations in temperature. Condensation can form on a suction line, and if this is insulated the insulation can become saturated.

This will encourage wet rot and fungal growth. In addition, the combination of a warm liquid line and wet materials will create an ideal environment for bacteria.

To overcome this problem a sleeve of metal or plastic, preferably the latter, should be inserted into the pipework aperture (Figure 71). The pipework is routed in the sleeve, which can then be sealed with a moisture and fire resis- tant compound. The sleeve is anchored firmly to a joist to avoid movement. Effective sealing of the sleeve prevents ingress of vermin. It also blocks off a supply of air, which would be undesirable if a fire started in the space below the floor. The sealing compound, being resilient, will prevent damage to pipework due to vibration.

The same principles should apply when pipework passes through a brick wall. The sleeve provided for an outside wall must protrude 25 mm to deny entry of rain water into the sleeve (see Figure 72).

Under no circumstances must electrical cables occupy the same sleeve as the refrigerant carrying pipework.

A condensing unit may be located on the ceiling of a small coldroom. It must be mounted on load bearing members; the weight of the unit will then be taken up by the supporting walls of the coldroom, thus preventing any sagging of the ceiling and subsequent breakdown of the insulation. An example is given in Figure 73.

Oil traps

Suct on l ne o l traps

High suction line risers will inevitably lead to compressor lubrication problems if provision for oil return is not made. When the compressor is located above the evaporator, an oil trap must be installed.

During low suction pressure operation at the end of a cooling cycle, the oil will tend to separate from the suction vapour and cling to the surface of the tubing. It will drain back to become entrained in the evaporator during off cycles. The oil trap will collect the oil, and when the compressor restarts the higher suction pressure will return most of it to the compressor.

An excessive amount of oil in the evaporator will reduce the evaporator capacity.

Oil traps can be of a U formation or of the barrel type; both perform the same function. A typical suction oil trap, formed in the suction line during installation, is depicted in Figure 73. On larger installations the higher suction riser will need more oil traps, as depicted in Figure 74.

D scharge l ne o l traps

These are installed or formed in high discharge risers (Figure 74) to prevent oil from draining back to the compressor head during off cycles. If it is present in the head a dynamic pressure will develop as the compressor restarts,

resulting in damage to the compressor valves, blown gaskets and possibly broken connecting rods and drive shafts.

resulting in damage to the compressor valves, blown gaskets and possibly broken connecting rods and drive shafts.

Oil separators

A certain amount of oil leaves a compressor with the discharged refrigerant vapour. Large quantities may be prevented from circulating in the system by

Pipework and oil traps 119

using an oil separator. Most air conditioning systems employ one of three basic types; the most common is the float type.

Oil returns to the compressor after it has been collected in the separator. The oil separates from the discharged vapour because the vapour flow slows as it enters the separator. When a certain level of oil is reached, the float opens a valve to return the oil to the compressor crankcase.

The oil return line to the compressor crankcase must be of small diameter tubing (6 mm, 0.25 in) or a capillary. This will reduce the oil flow and prevent oil slugging in the compressor.

Some separators are serviceable (bolted construction), some are installed by brazing, and the smaller types have flare connections. An oil separator does not eliminate the necessity for oil traps. Figure 75 shows a typical method of installation.

The accumulator type of separator is used in the larger installations and is located in the suction lines. The bucket type, of much larger construction, is mainly used on industrial systems.

Refrigerant may condense to liquid and collect in the oil separator during long off cycles or during a manual shut-down period of long duration. This refrigerant liquid returning via the oil return line to the compressor could damage the compressor after restart. A check valve in the vapour outlet of the oil separator will reduce the possibility of compressor damage.

A solenoid valve installed in the oil return line and interlocked with the compressor motor starter is common practice. This ensures a positive shut- off in the return line, because the solenoid valve will be energized (open)

only when the compressor is operating, preventing oil and refrigerant from draining to the compressor crankcase during off cycles.

only when the compressor is operating, preventing oil and refrigerant from draining to the compressor crankcase during off cycles.

To minimize refrigerant condensation in the oil separator it should be installed as close to the compressor as possible, preferably in a warm location. The separator may be insulated to retard heat loss when the compressor stops.

An indicating sight glass and a hand shut-off valve are installed in the oil return line. In conjunction with the sight glass the shut-off valve can be used as a throttling device; it is adjusted so that liquid flow (oil and refrigerant) from the separator can be controlled to the compressor crankcase.

Discharge line mufflers

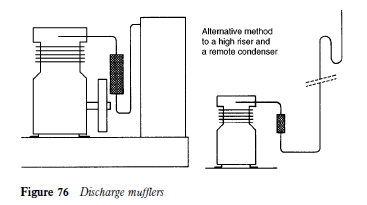

In the event of noise or vibration from gas pulsations, discharge mufflers are recommended and must be installed for the free draining of oil.

As previously stated, when compressors are idle the oil adhering to the inner surfaces of the discharge line risers will drain to the bottom of the risers. With a 3 m riser, plus the discharge muffler, the amount of oil can be quite considerable.

It is therefore advisable to loop the discharge line towards the floor to form a trap so that oil cannot drain to the compressor head. This trap will also collect any liquid refrigerant which may condense during the off cycle. It is especially important when the discharge line is in a cooler location than the condenser/receiver. Mufflers are normally installed vertically near the condensing unit to provide efficient oil movement. Figure 76 shows a discharge muffler installed in a discharge line loop.

When compressors are installed in parallel and share common suction and discharge lines, they are usually open-type units. Hermetic and semi-hermetic units are not used in case of a motor failure. The high temperatures resulting from the motor failure of one motor compressor can cause a chemical break- down of the refrigerant and oil, resulting in the contamination of the whole system.

However, two or more hermetic or semi-hermetic units can be used to accommodate a common load. When this is required each compressor is connected to an independent circuit within the evaporator and the condenser, so that they function without the possibility of cross-contamination. A single condenser is normally preferred for ease of control, but a separate condenser may be used for each compressor.

Discharge lines

Discharge lines should be installed so that the horizontal section is pitched downwards to join the common line. This will provide a free draining trap, preventing oil drain back to the idle compressor.

When the condenser is located above the compressors, separate risers should be used. Oil traps should be included at the base of each riser if the net lift to the condenser is more than 2 m. If the riser height is less than 2 m the oil traps may be omitted.

Figure 77 shows a basic pipework arrangement for discharge lines.

Discharge line equalizing

When individual condensers are installed, discharge lines must be equalized before they enter the condensers to allow them to function as one (Figure 78).

The pressure drop within equalizing lines is critical. For example, assume a pressure drop of 0.03 bar (0.5 psig) in the equalizer line. The pressure differential between an idle and an active condenser will cause condensed refrigerant from the active condenser to back through the liquid line to the idle condenser in an effort to equalize.

Crankcase equalizing

Obviously it is also necessary to prevent unequal oil distribution between the crankcases of the compressors. This is achieved by connecting an equalizer line to tappings provided (Figure 78).

The equalizer line size must be equal to the size of the tapping union. It is also essential that the compressors are mounted on the same level or that the oil levels are at the same height; compressor mounts can be adjusted to make this possible.

The equalizer line size must be equal to the size of the tapping union. It is also essential that the compressors are mounted on the same level or that the oil levels are at the same height; compressor mounts can be adjusted to make this possible.

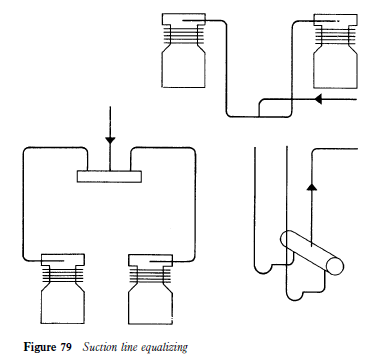

Suction line equalizing

Pipework should be routed to a manifold arrangement to equalize pressure at each unit. Common suction lines will drain freely, so this method is suitable for most systems (Figure 79).

When the evaporator is at a lower level than the compressor, the suction line should be pitched downwards. There should be two oil traps approximately

0.5 m (20 in) in height when suction risers are in excess of 3 m (10 ft).

Soft copper tubing up to 22 mm (7/8 in) diameter may be joined with flare fittings or by brazing. Hard drawn copper tubing is brazed. Iron and steel pipework is welded; cost restricts the use of welding to large industrial and ammonia systems, and it is not described here.

lare fittings

Flare connections will be perfectly satisfactory if the flaring of the tubing is carried out correctly.

Undersized or oversized flares are potential sources of leaks. In an under- sized flare the flare seat surface area is reduced and can allow movement within the flare fitting if the pipework is subjected to excessive vibration; the joint will eventually fracture. An oversized flare may prevent the correct seating to a union or a control; although it may well pass a leak test, a leak may develop when the pressures within the systems rise during operation. Flares are shown in Figure 80.

A good flare should allow withdrawal of the flare nut over the threads after it has been tightened down on to a union.

Brazing

Currently, most copper tubing is assembled with brazed joints because it is cheaper. In addition, if joints are made correctly the possibility of leaks is reduced.

In order to make a brazed joint the tubing has to be expanded. Various tools are available for this purpose: the punch-type expanders, swage formers used with a flare block and spinner, and the more elaborate tube expander.

The tube expander is generally used for larger diameter tubing, which may be hard or soft drawn copper. Hard drawn copper must be annealed before attempting to expand the tube. Annealing is a softening process, involving heating the tube and allowing it to cool.

When using a swage former or the expander, the depth of the swage will be determined by the former. It is approximately equivalent to the outside diameter of the tubing. Too shallow an expansion of the tube tends to produce a weak joint (see Figure 81).

Process

Brazing can be defined as jointing by applying high intensity heat to a high melting point alloy in order to fuse together two metal surfaces. It is often referred to as silver soldering.

Brazing rods should be cadmium free, and as described in BS 1845. All brazing should meet the requirements of BS 1723.

Hazards

Whilst it is possible to prefabricate some parts of the system pipework assembly in workshops, most brazing will be carried out on site.

The operator must be conversant with the site safety regulations and comply with fire regulations. Attention must be paid in particular to fire and smoke alarms whilst the brazing operations are being performed.

Where possible, work away from flammable materials such as wooden floors, joists and eaves. Use a protective metal or fire resistant sheet under conditions where a fire risk is obvious. Keep a fire extinguisher to hand when working in a risk area.

The number of brazed joints should be kept to a minimum, and the bending of copper tubing is preferred.

The number of brazed joints should be kept to a minimum, and the bending of copper tubing is preferred.

Preparation

All pipework and fittings to be brazed must be cleaned to remove dirt and oxides using a fine grade steel wool. A solvent may be necessary to remove preservative coatings from components or fittings.

Heat shields should always be used to protect areas surrounding the joint and to concentrate heat. Protect the system components, which could suffer damage when heat is applied, by wrapping a damp cloth around the component close to the joint.

Ensure that all joints are a tight fit. Support the pipework before brazing is attempted; any movement before the alloy has set can result in a leak or a weak joint.

Equipment usage

Select the correct pressure and nozzle (Table 5). Always light the blowtorch with a spark gun and not with matches or a cigarette lighter. Adjust the blowtorch to give the correct type of flame (see Figure 82).

Wear protective clothing and tinted goggles or glasses. Keep oxygen and acetylene cylinders away from any heat source. Always close down the equipment valves when leaving it unattended, even for a short period. Do not smoke when brazing. Note that toxic atmospheres are created during brazing operations when cadmium, galvanized metal and paint are heated.

Always pass nitrogen through the pipework or component being brazed to prevent oxidation and the formation of scale on the interior surfaces. Clean off all joints after brazing, especially when a flux has been used.

When brazing copper tubing, the joint area should be heated broadly with a continuous circular movement of the blowtorch until the copper changes colour to a cherry red; then apply the brazing rod. This will minimize the risk of local overheating and burnt tubing. Heat should be applied indirectly so that the rod and flux are melted by conduction through the base metal.