1.1 General

Direct-current electric machines (generators and motors)

have a wide field of application. The primary advantage of d.c. motors is that their speed can be readily varied as desired and that they can deve¬lop large starting torques. For this reason d.c. motors are widely used for electric traction tramways, trolleybuses and railways), and as drives in a variety of manufacturing and process plant.

Low power d.c. machines are employed to actuate final control elements and to serve as speed sensors in automatic control systems.

Direct-current generators are used to supply power for radio equipment, for battery charging, for electrolytic cells, and the like.

A disadvantage common to all d.c. machines is the complexity of design. mainly due to the use of brush gear . Apart from its com¬plex design, brush gear is subject to sparking. This reduces their reliability and limits their applicability. A substantional limitation is that a.c. supply for d.c. motors has to be first converted to d.c.

1.2 Construction of D.C. Machines

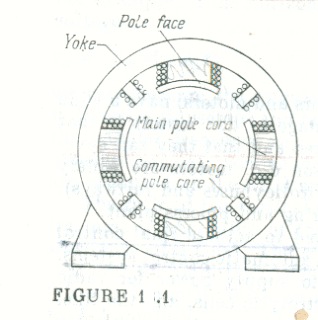

A d.c. machine consists essentially of a stationary part, called the field structure. which serves to excite the, main magnetic field. and a rotating part, called the armature, in which an emf is indued by the main magnetic field . The current produced by emf is indued by the main magnetic field and generates barking torque when the machine is operating as a generator, and driving torque when the machine is operating as a motor The field structure consists (fig 1.1 )

of a yoke which carries main poles to excite the main magnetic flux , and commutating poles to improve commutation (see Sec. 1.7) in the machine.

A main pole consists of a pole core (or shoe) built up of electrical-sheet steel laminations and bolted to the yoke, and a field coil wound the core. At its free end, the core has a pole face suitably shaped to ensure a uniform distribution of the magnetic flux around the armature .

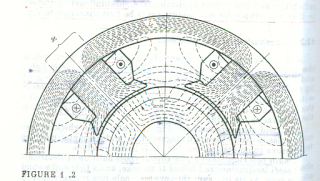

The yoke Φ (Fig.1.2)

. it is fabricated from cast steel rather than from laminations because the magnetic flux in it is relatively in magnitude .

The commutating poles (or compoles ) are bolted to the yoke midway Between the main poles . The compoles carry windings which are connected in series with the armature .

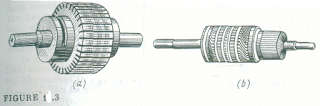

The armature is that part of a d.c. machine where an emf is induced as it rotates relative to the main field . the armature coninduced as it rotates relative to the main field . the armature consist of a toothed core , a winding dropped in the core slots ,and a commutator mounted on the armature shaft. The armature core is composed of electrical-sheet steel laminations (Fig. 1.3 a) usually 0.5 mm thick, insulated from one another with varnish. The armature winding consists of sections, or coils (Fig. 1.3 b).

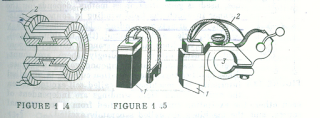

The commutator, which is a typical component of d.c. machines, is a hollow cylinder assembled from wedge-shaped copper bars, 1, insulated from one another and from the shaft with mica (Fig. 1.4). Conductors 2 connect the commutator bars to the coils of the armature winding in the slots. The armature winding is connected to the external circuit by the sliding contact that is formed between the commutator bars and brushes.

The brushes, 1, mounted in a box type of brushholder (Fig. 1.5) and are held on the commutator by a spring, 2, which gives a sufficient pressure. Current is conducted away from a brush (as in a generator ) or to a brush (as in a motor) by a pigtail. The brushholders are mounted on brush arms (also called brush studs or brackets which pass through a hole, 3, in each brushholder. In turn, the brush arms are secured to a brush yoke or rocker arm from which they are electrically insulated. The brush yoke or rocker arm is positioned coaxially with the armature so that it can be turned to change the location of the brushes relative to the poles of the machine.

As is the case with all electrical machines, a d.c._ machine is reversible . That is, it can operate as a generator if it is driven by

a primary mover, the main magnetic field is excited and the armature circuit is connected via the brushes to a load. In the circumstances, the emf induced in the armature winding gives rise to a current in the armature and the load. The interaction of the armature current with the main magnetic field produces at the shaft a braking torque which is overcome by the prime mover, In this way, a d.c. generator converts mechanical energy into electric energy.

when a d.c. machine is operating as a motor, the_armature and field circuits are connected to a power source . The interaction of the armature current with the main field produces a driving torque which

vercomes the load torque applied to the shaft, thereby converting electric energy into mechanical energy .

In other words, one and the same d.c. machine can be used as a generator and as a motor.

Direct-current machines may be classed according to several features, the main form of classification being according to the method of excitation of the main magnetic field. In some machines this purpose.

Is served by using permanent magnets on the poles. In many present-day machines, the main magnetic field is exerted by electromagnets which are called field coils because they consist of coils carrying the field-excitation current and put on the field-structure poles. The performance of d.c. machi¬nes, used as generators or as motors, depends on the manner in which the field winding is connected relative to the armature winding. The connection may be shunt series, and compound (that is, shunt-series), or the two windings may be arranged to be independent of eash other. Accordingly, there are shuntwound, series-wound and compound-wound machines. Since in all of them the excitation current is supplied internally, the machines are called self-excited. When the armature and field windings are independent of each other, the excitation current is supplied from some external source, and the machines are called separately excited.

A fact of practical importance is that with any form of connection the power taken by the field structure is relatively small, being about 5% of the power rating for small machines, and less than 1 % for large machines. This offers an economical means for controlling the operation of d.c. machines (the voltage of a generator and the an¬gular speed of a motor).

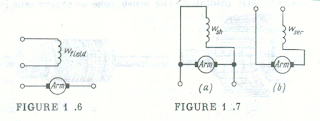

As already noted, in a separately excited d.c. machine the field winding is connected to some external source (Fig 1.6 ) so the current in the machine does not depend on the voltage across the armature terminals. The conductor size for the field winding of a sepa-rately excited machine is chosen to suit the voltage of a separately excited machine is chosen to suit the voltage of the external source . what is characteristic of separately exited machines is that the main field is independent of the load sustained by the machines .

In a shunt machine, the field winding is connected in parallel with the armature winding (Fig. 1.7 a). Now the excitation current, Ifield, is a small fraction (0.05-0.01) of the armature current, where¬ as the same voltage V exists between the terminals of the armature winding and the field winding. In consequence, the resistance of the field winding, rfield = V/Ifield , must he relatively high. Therefore, the field winding of a shunt machine is wound with many turns, wsh , of fine wire. What is characteristic of shunt machines operat¬ing within a large-power system is that the main magnetic flux is nearly constant at all loads.

In a series machine, the armature current, /arm, is equal to the field current (Fig. 1.7 b), so it is wound with a heavy-gauge conductor . The current in a series field winding is large, so the desired mmf, IarmWser, can be obtained with a relatively small number of turns, wser. Therefore, the resistance of a series field winding, rser, is re¬latively low. The feature typical of series machines is that the main magnetic flux varies noticeably with changes in load due to changes in the armature current which is at the same time the field current. In a compound machine, each pole Carries two windings (Fig. 1.8). That connected in parallel with the armature is the main winding, and the mmf it produces, Ishwsh, sets up the main magnetic field. The other is a series winding, wser, which only assists in controlling the magnetic field. Depending on which of the two mmfs predomi¬nates, the performance may be that of a series machine with a small shunt winding, or of a shunt machine with a small series winding. In most compound machines, the two windings are connected to aid each other, so that their mmfs are combined. Sometimes, the series winding is arranged to oppose the shunt winding, which means that their mmfs act in opposite directions. This arrangement is used in a few special cases.