TEST EQUIPMENT

Microelectronic developments have had a great impact on the test equipment, tools, and facilities necessary to maintain systems using this technology. This section discusses, in general terms, the importance of these developments.

Early electronic systems could be completely checked-out with general-purpose electronic test equipment (GPETE), such as multimeters, oscilloscopes, and signal generators. Using this equipment to individually test the microelectronics components in one of today’s very complex electronic systems would be extremely difficult if not impossible. Therefore, improvements in system testing procedures have been necessary.

One such improvement in system testing is the design of a method that can test systems at various functional levels. This allows groups of components to be tested as a whole and reduces the time required to test components individually. One advantage of this method is that complete test plans can be written to provide the best sequencing of tests for wave shape or voltage outputs for each functional level. This method of testing has led to the development of special test sets, called AUTOMATED TEST EQUIPMENT (ATE). These test sets are capable of simulating actual operating conditions of the system being tested. Appropriate signal voltages are applied by the test set to the various functional levels of the system, and the output of each level is monitored. Testing sequences are prewritten and steps may be switched-in manually or automatically. The limits for each functional level are preprogrammed to give either a "go/no-go" indication or diagnose a fault to a component. A go/no-go indication means that a functional level either meets the test specifications (go) or fails to meet the specifications (no-go).

If a no-go indication is observed for a given function, the area of the system in which it occurs is then further tested. You can test the trouble area by using general purpose electronic test equipment and the troubleshooting manual for the system. General purpose electronic test equipment (GPETE) will be discussed later in this topic. (Effective fault isolation at this point depends on the experience of the technician and the quality of the troubleshooting manual.) After the fault is located, the defective part is then replaced or repaired, depending on the nature of the defect. At this stage, the defective part is usually a circuit card, a module, or a discrete part, such as a switch, relay, transistor, or resistor.

BUILT-IN TEST EQUIPMENT

One type of fault isolation that can be either on-line or off-line is BUILT-IN TEST EQUIPMENT (BITE). BITE is any device that is permanently mounted in the prime equipment (system); it is used only for testing the equipment or system in which it is installed either independently or in association with external test equipment. The specific types of BITE are too varied to discuss here, but may be as simple as a set of meters and switches or as complex as a computer-controlled diagnostic system.

ON-LINE TEST EQUIPMENT

Functional-level testing and modular design have been successfully applied to most electronic systems in use today; however, the trend toward increasing the number of subassemblies within a module by incorporating microelectronics will make this method of testing less and less effective.

The increased circuit density and packaging possible with microelectronic components makes troubleshooting and fault location difficult or, in some cases, impossible. The technician’s efforts must be aided if timely repairs to microelectronic systems are to be achieved. These repairs are particularly significant when considered in the light of the very stringent availability requirements for today’s systems. This dilemma has led to the present trend of developing both ON-LINE and OFF-LINE automatic test systems. The on-line systems are designed to continuously monitor performance and to automatically isolate faults to removable assemblies. Off-line systems automatically check removable assemblies and isolate faults to the component level.

Two on-line systems, the TEST EVALUATION AND MONITORING SYSTEM (TEAMS) and the CENTRALIZED AUTOMATIC TEST SYSTEM (CATS), are presently in production or under development by the Navy.

Test Evaluation and Monitoring System (TEAMS)

TEAMS is an on-line system that continuously monitors the performance of electronic systems and isolates faults to a removable assembly. This system is controlled by a computer using a test program on perforated or magnetic tape, cassettes, or disks. Displays are used to present the status of the equipment and to provide data with instructions for fault localization. Lights, usually an LED, are used to indicate which equipments are being tested and also which equipments are in an out-of-tolerance condition. A printer provides a read out copy of the test results. These results are used by maintenance personnel to isolate the fault in a removable assembly to a replaceable part.

Centralized Automatic Test System (CATS)

CATS is an on-line system that continuously monitors the performance of electronic systems, predicts system performance trends, and isolates faults to removable assemblies. CATS, however, is computer controlled and the instructions are preprogrammed in the computer memory. The status of the electronic system being monitored by CATS is presented in various forms. Information concerning a failed module is presented on a status- and fault-isolation indicator to alert the maintenance technician of the need for a replacement module. If equipment design does not permit module replacement, complete electrical schematics and fault-isolation procedures will be made available to the maintenance technician.

OFF-LINE TEST EQUIPMENT

The Navy has under development an advanced assembly tester designated Naval Electronics Laboratory Assembly Tester (NELAT). This tester is an off-line, general-purpose test system designed to check-out and isolate faults in electronic plug-in assemblies, modules, and printed circuit boards. Equipped with a complete range of instrumentation, the system allows testing to be accomplished automatically, semiautomatically, or manually. In the automatic mode, a complete range of stimuli generators and monitors are connected and switched by means of a microfilmed test program.

The NELAT incorporates modular electronic assemblies that will facilitate updating of the system. The system is designed for use aboard ship. When put into service, this tester will greatly improve the technician’s capability in the checkout and fault isolation of microelectronic assemblies.

Another important system for off-line testing is the Versatile Avionic Shop Test System (VAST). VAST is used in the aviation community for fault isolation in aviation electronics (avionics) equipment on ships and shore commands with aircraft INTERMEDIATE MAINTENANCE DEPARTMENTS (AIMDs). It is an automatic, high-speed, computer controlled, general-purpose test set that will isolate faults to the component level.

GENERAL-PURPOSE ELECTRONIC TEST EQUIPMENT (GPETE)

When no automatic means of accomplishing fault isolation is available, general-purpose electronic test equipment and good troubleshooting procedures is used; however, such fault diagnosis should be attempted only by experienced technicians. Misuse of electrical probes and test equipment may permanently damage boards or microelectronic devices attached to them. The proximity of leads to one another and the effects of interconnecting the wiring make the testing of boards extremely difficult; these factors also make drift or current leakage measurements practically impossible.

Boards that have been conformally coated are difficult to probe because the coating is often too thick to penetrate for a good electrical contact. These boards must be removed for electrical probe testing. Many boards, however, are designed with test points that can be monitored either with special test sets or general-purpose test equipment. Another method of obtaining access to a greater number of test points is to use extender cards or cables. The use of extender cards or cables makes these test points easier to check.

Special care should be exercised when probing integrated circuits; they are easily damaged by excessive voltages or currents, and component leads may be physically damaged. Precautions concerning the use of test equipment for troubleshooting equipments containing integrated circuits are similar to those that should be observed when troubleshooting equipment containing semiconductor or other voltage and current-sensitive devices.

Voltage and resistance tests of resistors, transistors, inductors, and so forth, are usually effective in locating complete failures or defects that exhibit large changes from normal circuit characteristics; however, these methods are time-consuming and sometimes unsuccessful. The suspect device often must be desoldered, removed from the circuit, and then retested to verify the fault. If the defect is not verified, the device must be resoldered to the board again. If this procedure has to be repeated several times, or if the board is conformally coated, the defect may never be located. In fact, the circuit may be further damaged by the attempt to locate the fault. For these reasons, the device should never be desoldered until all possible in-circuit tests are performed and the defect verified.

Q7. List the three groups of test equipment used for fault isolation in 2M repair. Q8. What test equipment continuously monitors electronic systems?

Q9. NELAT and VAST are examples of what type of test equipment?

REPAIR STATIONS

In addition to the requirements for special skills, the repair of 2M electronic circuits also requires special tools. Because these tools are delicate and expensive, they are distributed only to trained and certified 2M repair technicians.

2M repair stations are equipped with electrical and mechanical units, tools, and general repair materials. Such equipments are needed to make reliable repairs to miniature and microminiature component circuit boards.

Although most of the tools and equipments are common to both miniature and microminiature repair stations, several pieces of equipment are used solely with microminiature repair. Precision drill presses and stereoscopic-zoom microscopes are examples of microminiature repair equipment normally not found in a miniature repair station. A brief description of some of the tools and equipments and their uses will broaden your knowledge and understanding of 2M repair.

The 2M repair set consists of special electrical units, tools, and materials necessary to make high- reliability repairs to component circuitry. The basic repair set is made up of a repair station power unit, magnifier/light system, card holder, a high-intensity light, a Pana Vise, and a tool chest with specialized tools and materials. As mentioned previously, stations that have microminiature repair capabilities will include a stereoscopic-zoom microscope and precision drill press.

REPAIR STATION POWER UNIT

The repair station power unit is a standardized system that provides controlled soldering and desoldering of all types of solder joint configurations. The unit is shown in figure 2-1. Included in the control unit’s capabilities are:

Figure 2-1.—Repair station power unit.

-

· "Spike free" power switching for attached electrical hand tools to eliminate damage to electrostatic discharge components.

-

· Abrading, milling, drilling, grinding, and cutting using a flexible shaft, rotary-drive machine.

This allows the technician to remove conformal coatings, oxides, eyelets, rivets, damaged board

material, and damaged platings from assemblies.

-

· Lap flow solder connections and thermal removal of conformal coatings.

-

· Resistive and conductive tweezer heating for connector soldering applications.

-

· Thermal wire stripping for removing polyvinyl chloride (PVC) and other synethetic wire coverings.

Power Source

The basic unit houses the power supply, power level indicator, motor control switch, hand tool temperature controls, air pressure and vacuum controls with quick connect fittings, positive ground terminal, the mechanical power-drive for the rotary-drive machine, and a vacuum/pressure pump. A two- position foot pedal, to the left of the power unit in the illustration, allows hand-free operation for all ancillary (additional) handpieces. The first detent on the pedal provides power to the voltage heating outputs. The second detent activates the motor drive or vacuum/pressure pump.

Handpieces

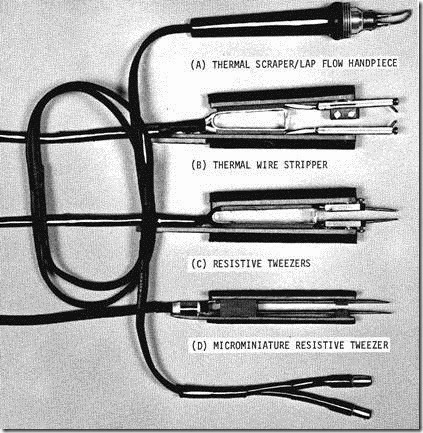

The handpieces used with the power unit are shown in figures 2-2 and 2-3. The lap flow handpiece, view (A) of figure 2-2, is used with the variable low-voltage power source. This handpiece allows removal of conformal coatings, release of sweat joints, and lap flow soldering capability. (Lap flow soldering will be discussed in topic 3.) The thermal wire stripper in view (B) is used to remove insulation from various sizes of wire easily and cleanly.

Figure 2-2.—Low voltage Handpiece.

Figure 2-3.—Motorized solder extrator.

The resistive tweezers, shown in view (C), are used for soldering components. Two sizes 173 views are provided to meet the needs of the technician. Both the thermal stripper and the resistive tweezers are used with the low-voltage power supply.

The solder extractor, shown in view (A) of figure 2-3, is connected to the variable high-voltage outlet. This handpiece allows airflow application (at controlled temperatures) of a vacuum or pressure to the selected area. Five sizes of extractor tips are provided, as shown in view (B). You can determine the one to be used by matching the tip with the circuit pad and the component being desoldered.

Soldering Irons

A soldering iron is shown in figure 2-4. This is connected to the 115-volt ac variable outlet of the power unit. You control the temperature by adjusting the voltage. The iron has replaceable tips. Chosen for their long life and good heat conductivity, soldering iron tips are high quality with iron-clad over copper construction. The tip shape and size and the heat range used are determined by the area and mass to be soldered.

Figure 2-4.—Soldering iron.

ROTARY-DRIVE MACHINE

This variable-speed, rotary power drive adapts to standard diameter shank drill bits, ball mills, wheels, disks, brushes, and mandrels for most drilling and abrasive removal techniques (figure 2-5).

Figure 2-5.—Rotary-drive machine handpieces.

The accessories used with the rotary-drive tool are shown in views (A) through (F) of figure 2-6. Abrasive ball mills, wheels, discs, and brushes are either premounted on mandrels or can be mounted by the technician on the mandrels provided. These attachments are used for sanding and smoothing repaired areas, drilling holes, removing conformal coatings, and repairing burned or damaged areas. A chuck- equipped handpiece allows it to accept rotary tools with varying shank sizes.

Figure 2-6.—Rotary-drive machine accessories. BALL MILLS

CIRCUIT CARD HOLDER AND MAGNIFIER

The circuit card holder is an adjustable, rotatable holder for virtually any size circuit card. Figure 2-7 shows the circuit card holder [view (A)] and the magnifier unit [view (B)]. The magnifier unit provides magnification when detail provided by a microscope is not required. The special lens allows the technician to view a rectangular area of over 14 square inches with low distortion, fine resolution, and excellent depth of field. The magnifier unit, which includes high intensity lamps, adapts to the vertical shaft of the circuit card holder.

Figure 2-7.—Card holder and magnifier.

HIGH-INTENSITY LIGHT

The high-intensity light provides a variable, high-intensity, portable light source over the work area. The two flexible arms permit both front and back lighting of the workpiece and provide a balanced light that eliminates shadows (figure 2-8).

Figure 2-8.—High intensity lamp.

The high-intensity light uses 115-volt, 60-hertz input power. One brightness knob controls a flood- type bulb, and the other knob controls a spot-type bulb.

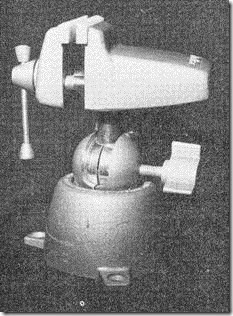

PANA VISE

This nylon-jawed, multiposition vise can rotate and tilt. With this flexibility the technician can achieve any compound angle for holding a workpiece during assembly, modification, or repair (figure 2-9).

Figure 2-9.—Pana Vise.

HAND TOOLS

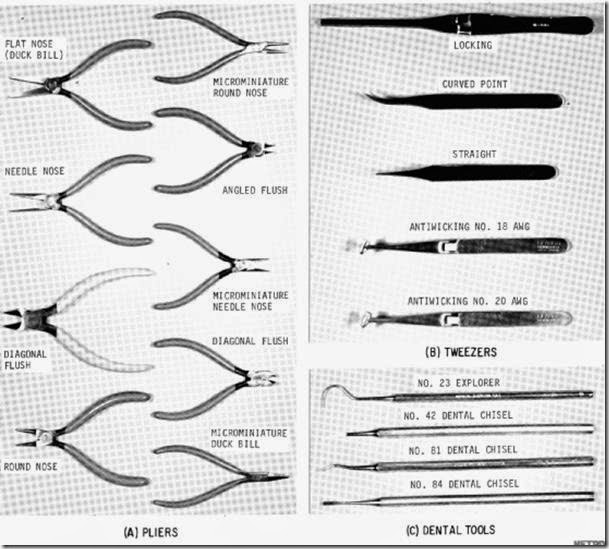

Figure 2-10, views (A) through (C), shows some representative types of hand tools used in 2M repair procedures.

Figure 2-10.—Pliers, tweezers, and dental tools.

Pliers

In view (A), the figure shows the pliers preferred for 2M repair procedures. These precision pliers have a long and useful life if handled and cared for properly. The flush-cutting pliers are used to cut various sizes of wire and component leads. The needlenose, roundnose, and flatnose pliers are used for forming, looping, and bending wires and component leads. They are also used for gripping components and leads during removal or installation.

Figure 2-10a.—Pliers.

Tweezers

View (B) shows tweezers contained in the 2M repair set. The top two pairs of tweezers are used to hold small components during installation and repair procedures. The other pairs are anti-wicking tweezers used to tin and solder stranded wire leads.

Dental Tools

View (C) shows some of the dental tools contained in the 2M repair set. They are used for picking, chipping, abrading, mixing, and smoothing various conformal coatings used on printed circuit boards and other general pcb repair techniques.

Figure 2-10c.—Dental tools.

Eyelet-Setting Tools

Among the repair procedures required of the 2M repair technician is the replacement of eyelets. Eyelets must sometimes be replaced because of the damage caused by incorrect repair procedures or complete failure of a printed circuit board. Figure 2-11 illustrates the tools used to replace these eyelets. Eyelets will be discussed in topic 3.

Figure 2-11.—Eyelet-setting tools.

MISCELLANEOUS TOOLS AND SUPPLIES

An assortment of some of the miscellaneous items used in 2M repair are shown in figure 2-12. A variety of brushes, files, scissors, thermal shunts, and consumables, such as solder wick, are included.

Even though all the items are not used in every repair procedure, it is extremely important that they be available for use should the need arise.

Figure 2-12.—Miscellaneous tools and supplies.

SAFETY EQUIPMENT

The nature of 2M repair requires items to be included in the tool kit for the personal safety of the technicians. The goggles and respirator illustrated in figure 2-13 have been approved for use by the technician. These should be worn at all times where dust, chips, fumes, and other hazardous substances are generated as a result of drilling, grinding, or other repair procedures.

Figure 2-13.—Safety equipment.

STEREOSCOPIC-ZOOM MICROSCOPE

The stereoscopic-zoom microscope provides a versatile optical viewing system. This viewing system is used in the fault detection, fault isolation, and repair of complex microminiature circuit boards and components. Figure 2-14 shows the microscope mounted on an adjustable stand. The microscope has a minimum of 3.5X and a maximum of 30X magnification to detect hairline cracks in conductor runs and stress cracks in solder joints.

Figure 2-14.—Stereoscopic zoom microscope.

TOOL CHEST

The tool chest (not shown), provides storage space for the electronic repair hand tools, dental tools, abrasive wheels, solder and solder wicks, eyelets, abrasive disks, ball mills, various burrs, and other consumables used with the repair procedures. The chest is portable, lockable, and has variously sized drawers for convenience.

REPLACEMENT PARTS

Replacement parts are provided with the 2M repair set to ensure the technician has the capability to maintain the equipment properly. Actual preventive and corrective maintenance procedures, as well as data on additional spare parts and ordering information, are found in the technical manual for the 2M repair set equipment.

REPAIR STATION FACILITIES

To be effective, 2M electronic component repair must be performed under proper environmental conditions. Repair facility requirements, whether afloat or ashore, include adequate lighting, ventilation, noise considerations, work surface area, ESD (electrostatic discharge) protection, and adequate power availability. The recommended environmental conditions are discussed below. With the exception of requirements imposed by the Naval Environmental Health Center and other authorities for ship and shore work conditions, each activity tailors the requirements to meet local needs.

LIGHTING

The recommended lighting for a work surface is 100 footcandles from a direct lighting source. Light- colored overheads and bulkheads and off-white or pastel workbench tops are used to complement the lighting provided.

VENTILATION

Fumes from burning flux, coating materials, grinding dust, and cleaning solvents require adequate ventilation. The use of toxic, flammable substances, solvents, and coating compounds requires a duct system that vents gasses and vapors. This type of system must be used to prevent contamination often

found in closed ventilation systems. This need is particularly important aboard ship. Vented hoods, ducts, or installations that are vented outside generally meet the minimum standards set by the Naval Environmental Health Center.

NOISE CONSIDERATIONS

Noise in the work area during normal work periods must be no greater than the acceptable level approved for each activity involved. Because the work is tedious and tiring, noise levels should be as low as possible. Ear protectors are required to be worn when a noise level exceeds 85 dB. Ear protectors should also be worn anytime the technician feels distracted by, or uncomfortable with, the noise level.

WORK SURFACE AREA

Work stations should have a minimum work surface of at least 60-inches wide and 30-inches deep. Standard Navy desks are excellent for this purpose. Standard shipboard workbenches are acceptable; however, off-white or pastel-colored heat-resistant tops should be installed on the workbenches. Chairs should be the type with backs and without arms. They should be comfortably padded and of the proper height to match the work surface height. Drawers or other suitable tool storage areas are usually provided.

ELECTROSTATIC DISCHARGE SENSITIVE DEVICE (ESDS) CAPABILITY

A 2M work station should be capable of becoming a static-free work station. This is specified in the Department of Defense Standard, Electrostatic DISCHARGE Control Program for Protection of Electrical and Electronic Parts, Assemblies, and Equipment. ESD will be discussed in greater detail in topic 3.

POWER REQUIREMENTS

No special power source or equipment mounting is required. The 2M repair equipment operates on 115-volt, 60-hertz power. A 15-ampere circuit is sufficient and six individual power receptacles should be available.

HIGH-RELIABILITY SOLDERING

The most common types of miniature and microminiature repair involve the removal and replacement of circuit components. The key to these repairs is a firm knowledge of solder and high- reliability soldering techniques.

Solder is a metal alloy used to join two or more metals with a metallic bond. The bonding occurs when molten solder dissolves a small amount of the metals and then cools to form a solid connection. The solder most commonly used in electronic assemblies is an alloy of tin and lead. Tin-lead alloys are identified by their percentage in the solder; the tin content is given first. Solder marked 60/40 is an alloy of 60 percent tin and 40 percent lead. The two most common alloys used in electronics are 60/40 and 63/37.

The melting temperature of tin-lead solder varies depending on the percentage of each metal. Lead melts at a temperature of 621 degrees Fahrenheit, and tin melts at 450 degrees Fahrenheit. Combinations of the two metals melt into a liquid at different temperatures. The 63/37 combination melts into a liquid at 361 degrees Fahrenheit. At this temperature, the alloy changes from a solid directly to a liquid with no plastic or semiliquid state. An alloy with such a sharp changing point is called a EUTECTIC ALLOY.

As the percentages of tin and lead are varied, the melting temperature increases. Alloy of 60/40 melts at 370 degrees Fahrenheit, and alloy of 70/30 melts at approximately 380 degrees Fahrenheit. Alloys, other than eutectic, go through a plastic or semiliquid state in their heating and cooling stages. Solder joints that are disturbed (moved) during the plastic state will result in damaged connections. For this reason, 63/37 solder is the best alloy for electronic work. Solder with 60/40 alloy is also acceptable, but it goes into a plastic state between 361 and 370 degrees Fahrenheit. When soldering joints with 60/40 alloy, you must exercise extreme care to prevent movement of the component during cooling.

USE OF FLUX IN SOLDER BONDING

Reliable solder connections can only be accomplished with clean surfaces. Using solvents and abrasives to clean the surfaces to be soldered is essential if you are to achieve good solder connections. In almost all cases, however, this cleaning process is insufficient because oxides form rapidly on heated metal surfaces. The rapid formation of oxides creates a nonmetallic film that prevents solder from contacting the metal. Good metal-to-metal contact must be obtained before good soldering joints may take place. Flux removes these surface oxides from metals to be soldered and keeps them removed during the soldering operation. Flux chemically breaks down surface oxides and causes the oxide film to loosen and break free from the metals being soldered.

Soldering fluxes are divided into three classifications or groups: CHLORIDE FLUX (commonly called ACID), ORGANIC FLUX, and ROSIN FLUX. Each flux has characteristics specific to its own group. Chloride fluxes are the most active of the three groups. They are effective on all common metals except aluminum and magnesium. Chloride fluxes, however, are NOT suitable for electronic soldering because they are highly corrosive, electrically conductive, and are difficult to remove from the soldered joint.

Organic fluxes are nearly as active as chloride fluxes, yet are less corrosive and easier to remove than chloride fluxes. Also, these fluxes are NOT satisfactory for electronic soldering because they must be removed completely to prevent corrosion.

Rosin fluxes ARE ideally suited to electronic soldering because of their molecular structure. The most common flux used in electronic soldering is a solution of pure rosin dissolved in suitable solvent. This solution works well with the tin- or solder-dipped metals commonly used for wires, lugs, and connectors. While inert at normal temperatures, rosin fluxes break down and become highly active at soldering temperatures. In addition, rosin is nonconductive.

Most electronic solder, in wire form, is made with one or more cores of rosin flux. When the joint or connection is heated and the wire solder is applied to the joint (not the iron), the flux flows onto the surface of the joint and removes the oxide. This process aids the wetting action of the solder. With enough heat the solder flows and replaces the flux. Insufficient heat results in a poor connection because the solder does not replace the flux.

Q10. Stereoscopic-zoom microscopes and precision drill presses are normally associated with what type of repair station?

Q11. Solder used in electronic repair is normally an alloy of what two elements? Q12. In soldering, what alloy changes directly from a solid state to a liquid state? Q13. Flux aids in soldering by removing what from surfaces to be soldered?

Q14. What type(s) of flux should never be used on electronic equipment?