CRYSTAL OSCILLATORS

Crystal oscillators are those in which a specially-cut crystal controls the frequency. CRYSTAL- CONTROLLED OSCILLATORS are the standard means used for maintaining the frequency of radio transmitting stations within their assigned frequency limits. A crystal-controlled oscillator is usually used to produce an output which is highly stable and at a very precise frequency.

As stated earlier, crystals used in electrical circuits are thin sheets cut from the natural crystal and are ground to the proper thickness for the desired resonant frequency. For any given crystal cut, the thinner the crystal, the higher the resonant frequency. The "cut" (X, Y, AT, and so forth) of the crystal means the precise way in which the usable crystal is cut from the natural crystal. Some typical crystal cuts may be seen in figure 2-19.

Transmitters which require a very high degree of frequency stability, such as a broadcast transmitter, use temperature-controlled ovens to maintain a constant crystal temperature. These ovens are thermostatically controlled containers in which the crystals are placed.

Transmitters which require a very high degree of frequency stability, such as a broadcast transmitter, use temperature-controlled ovens to maintain a constant crystal temperature. These ovens are thermostatically controlled containers in which the crystals are placed.

The type of cut also determines the activity of the crystal. Some crystals vibrate at more than one frequency and thus will operate at harmonic frequencies. Crystals which are not of uniform thickness may have two or more resonant frequencies. Usually one resonant frequency is more pronounced than the others. The other less pronounced resonant frequencies are referred to as SPURIOUS frequencies. Sometimes such a crystal oscillates at two frequencies at the same time.

The amount of current that can safely pass through a crystal ranges from 50 to 200 milliamperes. When the rated current is exceeded, the amplitude of mechanical vibration becomes too great, and the crystal may crack. Overloading the crystal affects the frequency of vibration because the power dissipation and crystal temperature increase with the amount of load current.

Crystals as Tuned Circuits

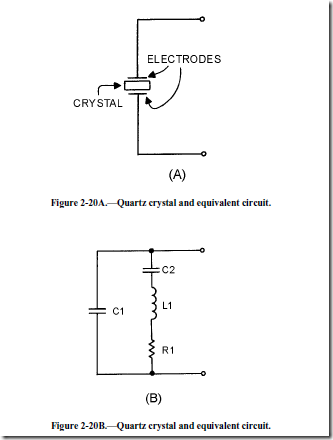

A quartz crystal and its equivalent circuit are shown in figure 2-20, views (A) and (B). Capacitor C2, inductor L1, and resistor R1 in view (B) represent the electrical equivalent of the quartz crystal in view (A). Capacitance C1 in (view B) represents the capacitance between the crystal electrodes in view (A). Depending upon the circuit characteristics, the crystal can act as a capacitor, an inductor, a series-tuned circuit, or a parallel-tuned circuit.

At some frequency, the reactances of equivalent capacitor C1 and inductor L will be equal and the crystal will act as a series-tuned circuit. A series-tuned circuit has a minimum impedance at resonance (figure 2-21). Above resonance the series-tuned circuit acts INDUCTIVELY, and below resonance it acts CAPACITIVELY. In other words, the crystal unit has its lowest impedance at the series-resonance frequency. The impedance increases as the frequency is lowered because the unit acts as a capacitor. The impedance of the crystal unit also increases as the frequency is raised above the series-resonant point because the unit acts as an inductor. Therefore, the crystal unit reacts as a series-tuned circuit.

Figure 2-21.—Frequency response of a crystal.

Since the series-tuned circuit acts as an inductor above the resonant point, the crystal unit becomes equivalent to an inductor and is parallel with the equivalent capacitor C1 (view (B) of figure 2-20). At some frequency above the series-resonant point, the crystal unit will act as a parallel-tuned circuit. A parallel-tuned circuit has a MAXIMUM impedance at the parallel-resonant frequency and acts inductively below parallel resonance (figure 2-21). Therefore, at some frequency, depending upon the cut of the crystal, the crystal unit will act as a parallel-tuned circuit.

The frequency stability of crystal-controlled oscillators depends on the Q of the crystal. The Q of a crystal is very high. It may be more than 100 times greater than that obtained with an equivalent electrical circuit. The Q of the crystal is determined by the cut, the type of holder, and the accuracy of grinding. Commercially produced crystals range in Q from 5,000 to 30,000 while some laboratory experiment crystals range in Q up to 400,000.

Crystal-Controlled Armstrong Oscillator

The crystal-controlled Armstrong oscillator (figure 2-22) uses the series-tuned mode of operation. It works much the same as the Hartley oscillator except that frequency stability is improved by the crystal (in the feedback path). To operate the oscillator at different frequencies, you simply change crystals (each crystal operates at a different frequency).

Variable capacitor C1 makes the circuit tunable to the selected crystal frequency. C1 is capable of tuning to a wide band of selected crystal frequencies. Regenerative feedback from the collector to base is through the mutual inductance between the transformer windings of T1. This provides the necessary 180-degree phase shift for the feedback signal. Resistors R B, RF, and RC provide the base and collector bias voltage. Capacitor CE bypasses ac variations around emitter resistor RE.

At frequencies above and below the series-resonant frequency of the selected crystal, the impedance of the crystal increases and reduces the amount of feedback signal. This, in turn, prevents oscillations at frequencies other than the series-resonant frequency.

Crystal-Controlled Pierce Oscillator

The crystal-controlled PIERCE OSCILLATOR uses a crystal unit as a parallel-resonant circuit. The Pierce oscillator is a modified Colpitts oscillator. They operate in the same way except that the crystal unit replaces the parallel-resonant circuit of the Colpitts.

Figure 2-23 shows the common-base configuration of the Pierce oscillator. Feedback is supplied from the collector to the emitter through capacitor C1. Resistors RB, RC, and RF provide the proper bias conditions for the circuit and resistor RE is the emitter resistor. Capacitors C1 and CE form a voltage divider connected across the output. Since no phase shift occurs in the common-base circuit, capacitor C1 feeds back a portion of the output signal to the emitter without a phase shift. The oscillating frequency is determined not only by the crystal but also by the parallel capacitance caused by capacitors C1 and CE. This parallel capacitance affects the oscillator frequency by lowering it. Any change in capacitance of either C1 or CE changes the frequency of the oscillator.

Figure 2-24 shows the common-emitter configuration of the Pierce oscillator. The resistors in the circuit provide the proper bias and stabilization conditions. The crystal unit and capacitors C1 and C2 determine the output frequency of the oscillator. The signal developed at the junction between Y1 and C1 is 180 degrees out of phase with the signal at the junction between Y1 and C2. Therefore, the signal at the Y1-C1 junction can be coupled back to the base of Q1 as a regenerative feedback signal to sustain oscillations.

Q-18. What is the impedance of a crystal at its resonant frequency when it is used in the parallel mode? Q-19. What is the impedance of a crystal at its resonant frequency when it is used in the series mode?